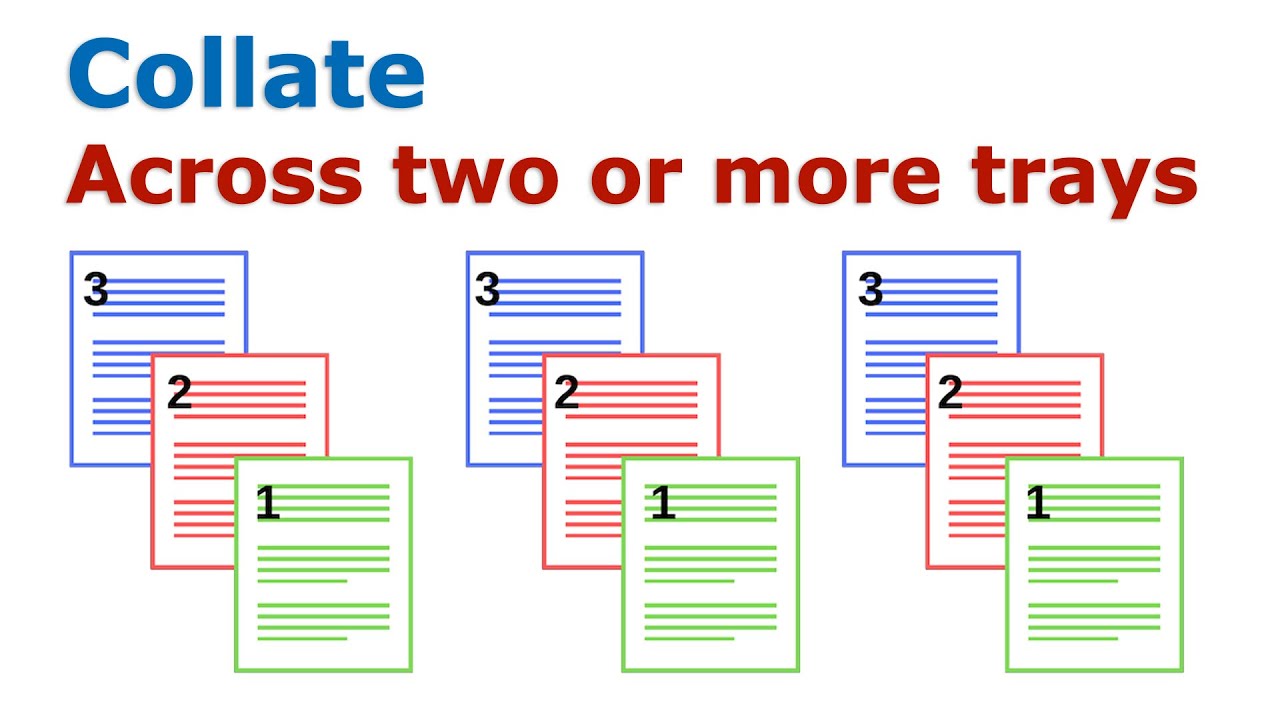

What does collated printing mean? Imagine you’re printing a multi-page document, like a report or a book. Collated printing means the pages are organized in the correct order, ready for binding or stapling. It’s like having a deck of cards perfectly sorted by suit and number, rather than a jumbled mess.

This makes the printing process much more efficient, especially for large projects.

Collated printing is a vital part of the printing process, especially for documents that require specific page order. It’s commonly used in businesses, schools, and publishing houses, and it’s essential for producing professional-looking documents.

Definition of Collated Printing

Collated printing refers to a printing method where pages are printed in the correct order and then assembled together to create a complete document. Think of it like assembling a puzzle – each page is a piece, and collated printing ensures that the pieces are put together in the right order.

Understanding Collated Printing

Collated printing ensures that pages are printed in the correct sequence, ready for binding or stapling. This is achieved by organizing pages in the correct order before printing. In contrast, non-collated printing produces pages in a random order, requiring manual sorting before assembly.

Collated printing is like getting your documents in order, with each page of a document together, instead of all mixed up. This can be super helpful for big projects, and with a Ricoh Document Scanner: Revolutionizing Document Management , you can scan your documents quickly and efficiently, making it easy to collate and organize your files for printing later.

Collated printing: pages are printed in the correct order.

Non-collated printing: pages are printed in a random order.

Process of Collated Printing

Collated printing is a method of printing that involves organizing and assembling pages in the correct order before they are bound or finished. This process ensures that the final printed document has pages in the correct sequence.

Steps Involved in Collated Printing

The collated printing process involves a series of steps, starting from the preparation stage and culminating in the final output. The following steps are involved in collated printing:

- Preparation:The first step involves preparing the printing files and setting up the printing equipment. This includes ensuring that the printing files are in the correct format and that the printing equipment is calibrated and ready to print.

- Printing:The printing process involves printing each page of the document separately. This is done on a high-speed printing press, which can print thousands of pages per minute.

- Collation:After printing, the pages are collated in the correct order. This can be done manually or using an automated collating machine. Collating machines use a series of feeders and conveyors to gather and organize the pages into the correct sequence.

- Binding:Once the pages are collated, they are bound together to create the final document. There are various binding methods available, including stapling, stitching, and perfect binding.

- Finishing:The final step involves finishing the document, which may include trimming, folding, and inserting covers.

Organization and Assembly of Pages, What does collated printing mean

In collated printing, pages are organized and assembled in the correct order to create the final document. This process ensures that the pages are arranged in the sequence they are intended to be read. The method of organization and assembly depends on the type of document being printed and the desired output.

- Sheetwise Collation:In sheetwise collation, the pages are organized into sheets, with each sheet containing a set of consecutive pages. For example, a sheet might contain pages 1-4, 5-8, and so on. The sheets are then collated in the correct order to form the final document.

- Signature Collation:In signature collation, the pages are organized into signatures, which are groups of folded sheets. Each signature contains a set of pages that are printed on both sides of the paper. The signatures are then collated in the correct order to form the final document.

Key Equipment and Technologies Used in Collated Printing

Collated printing relies on a variety of equipment and technologies to ensure efficient and accurate production. The following are some of the key equipment and technologies used in collated printing:

- High-Speed Printing Presses:These presses are capable of printing thousands of pages per minute, making them ideal for high-volume printing projects.

- Collating Machines:These machines automate the process of gathering and organizing pages in the correct order. They use a series of feeders and conveyors to move the pages through the machine and into the desired sequence.

- Binding Machines:These machines bind the collated pages together to create the final document. There are various types of binding machines, each suited for different types of documents and binding methods.

- Finishing Equipment:Finishing equipment is used to complete the final steps of the printing process, such as trimming, folding, and inserting covers.

- Digital Printing Systems:Digital printing systems are increasingly used in collated printing, as they offer flexibility and speed. Digital printing systems allow for on-demand printing and can be used to print a variety of documents, including books, brochures, and magazines.

Advantages of Collated Printing

Collated printing offers a range of benefits, making it a preferred choice for various projects. By organizing printed documents in the correct order, collated printing significantly enhances document organization and readability, streamlining workflows and improving user experience.

Benefits of Collated Printing

Collated printing delivers numerous advantages, enhancing efficiency, organization, and user experience. These benefits are particularly relevant for projects requiring multiple pages, ensuring documents are assembled correctly and easily navigated.

- Enhanced Organization:Collated printing ensures that pages are arranged in the correct sequence, simplifying document navigation and reducing the risk of misplaced or missing pages. This is especially crucial for lengthy documents, reports, and manuals, facilitating easy reference and information retrieval.

- Improved Readability:By presenting pages in the intended order, collated printing enhances document readability. Readers can effortlessly follow the flow of information, eliminating confusion and improving comprehension.

- Streamlined Workflows:Collated printing optimizes workflows by eliminating the need for manual sorting and assembling of documents. This saves time and resources, particularly for large print runs, and allows for efficient distribution and use.

- Professional Presentation:Collated printing conveys a sense of professionalism and attention to detail. Documents with pages in the correct order project a polished and organized image, enhancing the overall impression on recipients.

Industries Where Collated Printing is Beneficial

Collated printing is widely used across various industries, offering valuable benefits for specific applications. Its ability to organize documents effectively makes it a preferred choice for:

- Education:Collated printing is essential for educational institutions, facilitating the production of textbooks, handouts, and course materials. By ensuring pages are in the correct order, students can easily follow the curriculum and access information efficiently.

- Business:Businesses rely on collated printing for various applications, including reports, presentations, marketing materials, and proposals. The ability to organize documents professionally enhances communication and strengthens brand image.

- Legal:Legal professionals require accurate and organized documents for court filings, briefs, and contracts. Collated printing ensures the proper sequence of pages, crucial for maintaining legal validity and clarity.

- Healthcare:Collated printing is essential in healthcare, where patient records, medical reports, and insurance forms need to be organized and readily accessible. This ensures accurate information flow and facilitates efficient patient care.

Types of Collated Printing

Collated printing, as we’ve discussed, is a crucial aspect of many printing projects, ensuring that pages are arranged in the correct order for binding. However, the methods used for collating can vary significantly, each offering unique advantages and disadvantages. Let’s delve into the different types of collated printing to understand their nuances and best applications.

Manual Collation

Manual collation, as the name suggests, involves manually arranging pages in the correct order. This method is often used for smaller print runs or projects where speed is not a primary concern. It’s also a cost-effective option for small businesses or individuals who may not have access to automated collating equipment.

- Advantages:Cost-effective, suitable for small print runs, requires minimal specialized equipment.

- Disadvantages:Time-consuming, prone to errors, labor-intensive, not suitable for large print runs.

Offset Collation

Offset collation is a common method used in commercial printing. This method involves printing pages on separate sheets and then feeding them into a collating machine, which stacks them in the correct order. Offset collation is generally faster and more accurate than manual collation, making it ideal for large print runs.

- Advantages:High speed, accurate, suitable for large print runs, allows for the use of specialized finishing equipment.

- Disadvantages:Requires specialized equipment, can be more expensive than manual collation.

Digital Collation

Digital collation is a relatively new method that utilizes digital printing technology. In this process, pages are printed directly onto sheets of paper in the correct order. This eliminates the need for separate printing and collating steps, making it a highly efficient and accurate method.

- Advantages:Highly accurate, fast, eliminates the need for separate printing and collating steps, allows for variable data printing.

- Disadvantages:Can be more expensive than offset collation, may have limitations on paper types and sizes.

In-Line Collation

In-line collation is a method used in high-speed printing presses where pages are collated as they are printed. This method is extremely efficient and accurate, making it ideal for large-scale printing projects.

- Advantages:Extremely fast and accurate, eliminates the need for separate collating equipment, suitable for high-volume printing.

- Disadvantages:Requires specialized high-speed printing presses, can be expensive.

Examples of Collated Printing Applications: What Does Collated Printing Mean

Collated printing is a valuable technique that finds applications across numerous industries. It streamlines the printing process and ensures that documents are assembled in the correct order, making it a crucial component in many everyday tasks.

Examples of Collated Printing Applications in Different Industries

Collated printing is a versatile technique that benefits various industries. The following table provides examples of documents or projects that leverage the advantages of collated printing:

| Document Type | Industry | Specific Application of Collated Printing |

|---|---|---|

| Brochures | Marketing & Advertising | Collated printing ensures that pages are in the correct sequence for a professional and organized brochure. |

| Booklets | Publishing & Education | Collated printing is essential for assembling booklets with multiple pages, guaranteeing the right order for a cohesive reading experience. |

| Manuals & Instructions | Manufacturing & Technology | Collated printing plays a vital role in creating manuals and instructions with multiple pages, ensuring that users have the complete and accurate information. |

| Financial Reports | Finance & Accounting | Collated printing ensures that financial reports with numerous pages are organized correctly for efficient review and analysis. |

| Legal Documents | Law & Legal Services | Collated printing is crucial for assembling legal documents with multiple pages, guaranteeing the proper sequence for accurate and reliable legal proceedings. |

FAQ Section

What are the main differences between collated and non-collated printing?

Collated printing ensures pages are in the correct order, while non-collated printing delivers pages in a single stack, requiring manual sorting.

Is collated printing always necessary?

While not always essential, collated printing is highly recommended for multi-page documents, especially when a specific page order is crucial.

What are some common examples of collated printing applications?

Brochures, reports, magazines, books, and marketing materials are just a few examples where collated printing is widely used.