How to clean the nozzle of a 3D printer is a question every maker eventually faces. A clogged nozzle can lead to frustrating printing problems like skipped layers, inconsistent flow, and even filament jams. But don’t worry, cleaning your nozzle is a relatively simple process that can significantly improve the quality of your prints.

Whether you’re a seasoned 3D printing enthusiast or just starting out, understanding how to properly clean your nozzle is essential for maintaining your printer’s performance and achieving consistently excellent results.

This guide will walk you through the steps of identifying a clogged nozzle, gathering the right tools, and implementing effective cleaning methods. We’ll cover different nozzle types, preventative measures to avoid clogging, and even advanced techniques for stubborn clogs. By the end, you’ll be equipped with the knowledge and confidence to keep your nozzle clean and your 3D printer running smoothly.

Understanding the Importance of Nozzle Cleaning

Imagine your 3D printer as a tiny artist, meticulously laying down layers of plastic to create your designs. But what happens when the artist’s brush gets clogged with paint? The results are messy, inconsistent, and far from the beautiful masterpiece you envisioned.

Keeping your 3D printer nozzle clean is essential for smooth printing, just like ensuring your printer settings are optimized. You might think about things like “what is collated printing” what is collated printing when you’re dealing with regular printers, but with 3D printing, the nozzle is key.

Regular cleaning with a specialized tool or even a simple needle can make a huge difference in the quality of your prints.

That’s precisely what happens when your 3D printer nozzle gets clogged – it disrupts the smooth flow of filament, leading to a host of printing problems.Nozzle cleaning is an essential part of maintaining your 3D printer’s performance and ensuring high-quality prints.

A clean nozzle allows for a consistent flow of filament, resulting in smooth, detailed, and accurate prints.

Consequences of a Clogged Nozzle

A clogged nozzle can have a significant impact on your 3D printing experience. Here’s a breakdown of the common issues that arise when your nozzle is not clean:

- Poor Print Quality:A clogged nozzle can cause inconsistencies in filament flow, resulting in uneven layers, gaps, and rough surfaces. This significantly affects the overall quality and aesthetic appeal of your prints.

- Under Extrusion:When the nozzle is partially clogged, the filament flow is restricted, leading to under-extrusion. This results in thin, incomplete layers and weak prints.

- Filament Jams:A clogged nozzle can cause the filament to jam, leading to a complete halt in printing. This can be frustrating and time-consuming to resolve.

- Nozzle Damage:If the clog is severe, attempting to force filament through the nozzle can damage it, requiring replacement.

Common Printing Issues Caused by a Dirty Nozzle

Here are some common printing issues that often indicate a dirty nozzle:

- Stringing:This occurs when excess filament is deposited outside the print path, creating thin, stringy lines.

- Blobbing:When the filament flow is inconsistent, it can cause blobs or lumps on the print surface, affecting the smoothness of the final product.

- Layer Adhesion Problems:A dirty nozzle can lead to poor layer adhesion, resulting in layers separating or peeling off.

- Incomplete Prints:A clogged nozzle can cause the printer to stop mid-print, leaving your project incomplete.

Identifying Signs of a Clogged Nozzle

A clogged nozzle can significantly impact your 3D printing experience, leading to poor print quality, frustrating delays, and even damaged prints. It’s crucial to recognize the signs of a clogged nozzle early on to prevent further complications.

Visual Cues Indicating a Clogged Nozzle

A clogged nozzle can be identified through visual cues. Observing these signs early on can help you address the issue before it impacts your prints.

- Filament not extruding:If you observe that the filament is not extruding from the nozzle, it’s a strong indication of a clog. This is a common symptom, and it often occurs when the nozzle is completely blocked.

- Filament oozing out:In some cases, you might notice filament oozing out of the nozzle, but it’s not forming a consistent and continuous filament path. This suggests that the nozzle is partially clogged, preventing the filament from flowing freely.

- Discoloration or residue:If you see discoloration or residue around the nozzle, it could indicate that the filament has been partially melted and solidified within the nozzle, creating a blockage.

Common Symptoms Observed During Printing

The behavior of your 3D printer can also reveal the presence of a clogged nozzle. Here are some common symptoms to look out for:

- Skipping or missing layers:When a nozzle is clogged, the filament may not be able to flow smoothly, resulting in gaps or missing layers in your print.

- Uneven filament extrusion:A clogged nozzle can lead to inconsistent filament extrusion, creating uneven surfaces and inconsistent layer heights.

- Poor adhesion:The lack of proper filament flow due to a clog can also affect the adhesion between layers, causing prints to detach or become weak.

- Excessive filament oozing:If the nozzle is partially clogged, you might observe excessive filament oozing, resulting in messy prints with unwanted blobs of material.

Behavior of Filament When a Nozzle is Clogged

The filament’s behavior provides crucial insights into the extent of the clog.

- Filament not moving:When a nozzle is completely clogged, the filament will not move at all, even when the extruder is activated. This indicates a severe blockage requiring immediate attention.

- Filament moving but not extruding:If the filament moves through the extruder but doesn’t extrude from the nozzle, it suggests a partial clog. The filament might be able to move through the nozzle but cannot flow freely due to a blockage.

- Filament extruding unevenly:When the filament extrudes unevenly, it indicates that the nozzle is partially clogged, causing inconsistencies in the flow of material. This can lead to defects and imperfections in your prints.

Tools and Materials for Nozzle Cleaning

Nozzle cleaning requires a few essential tools and materials. These tools help you safely and effectively remove any obstructions from your nozzle, ensuring a smooth and reliable printing process.

Essential Tools and Materials

| Tool/Material | Description | Purpose | Alternative |

|---|---|---|---|

| Needle or Pin | A thin, pointed tool used to dislodge filament from the nozzle opening. | To clear blockages and remove debris from the nozzle orifice. | Paperclip, thin wire, or a small screwdriver. |

| Wire Brush | A small brush with fine bristles used to clean the nozzle opening and surrounding area. | To remove carbon buildup and other residue from the nozzle. | Toothbrush, cotton swab, or a soft cloth. |

| Isopropyl Alcohol (IPA) | A solvent used to clean and disinfect the nozzle and other printer components. | To dissolve and remove filament residue, grease, and other contaminants. | Denatured alcohol or a specialized 3D printer cleaning solution. |

| Paper Towels or Cloth | Absorbent materials used to dry the nozzle and other cleaned components. | To remove excess IPA and prevent moisture from affecting the printing process. | Cotton balls or a clean, lint-free cloth. |

| Gloves | Protective gear worn to prevent contamination of the nozzle and other components during cleaning. | To maintain hygiene and prevent the transfer of oils or dirt from your hands. | Clean hands and a workspace. |

Cleaning Methods for Different Nozzle Types

Nozzles are the heart of a 3D printer, responsible for extruding the filament and creating your 3D prints. Over time, they can get clogged with melted filament, dust, or other debris, leading to poor print quality. Cleaning your nozzle regularly is crucial for maintaining optimal performance and preventing costly repairs.Different nozzle types have different cleaning requirements.

We’ll delve into the most common types and their respective cleaning methods.

Nozzle Types and Cleaning Methods

Nozzle types are classified based on their material, size, and design. Each type has specific cleaning methods tailored to its properties.

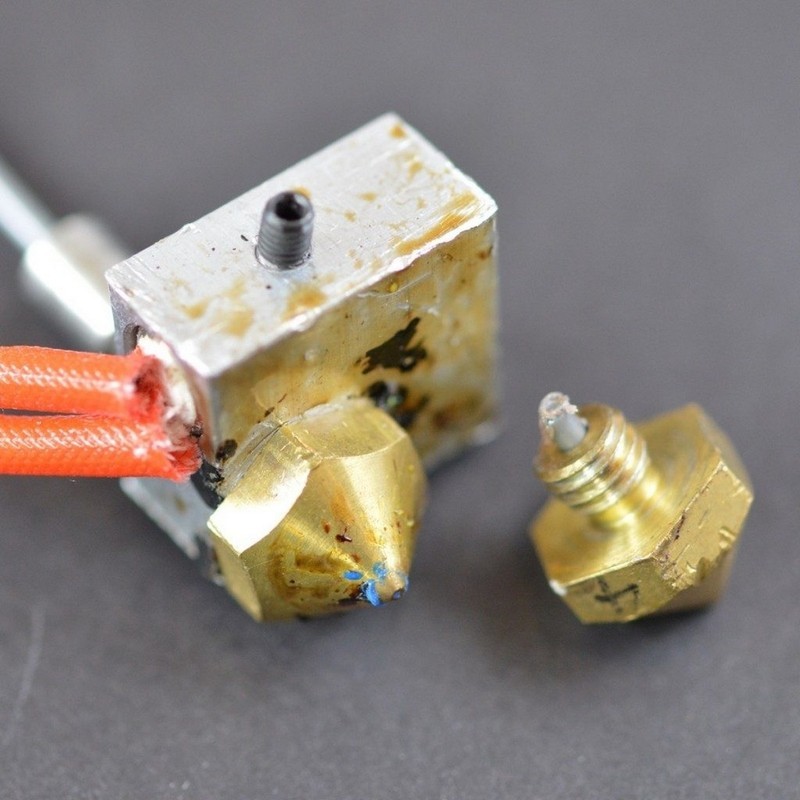

- Brass Nozzles: Brass nozzles are the most common type due to their affordability and good thermal conductivity. They are generally easy to clean using a variety of methods, including mechanical cleaning, chemical cleaning, and a combination of both.

- Steel Nozzles: Steel nozzles are more durable and resistant to wear and tear than brass nozzles. They are also more resistant to corrosion. However, they can be more challenging to clean due to their harder material. Mechanical cleaning methods are generally preferred for steel nozzles.

- Hardened Steel Nozzles: Hardened steel nozzles offer the highest level of durability and wear resistance. They are ideal for printing abrasive materials like carbon fiber or wood filaments. Due to their hardness, cleaning hardened steel nozzles requires specialized tools and techniques.

- Ruby Nozzles: Ruby nozzles are highly resistant to wear and tear, making them suitable for printing abrasive materials. They are also very resistant to heat and corrosion. However, they are more expensive than other nozzle types and require careful cleaning to avoid damage.

Cleaning Brass Nozzles

Brass nozzles are relatively easy to clean, making them a popular choice for 3D printing.

- Mechanical Cleaning: Using a needle or a small wire brush to remove any debris stuck in the nozzle. This method is effective for removing loose debris but may not be suitable for removing hardened filament.

- Chemical Cleaning: Soaking the nozzle in a solvent like acetone or isopropyl alcohol can dissolve any remaining filament residue. This method is effective for removing hardened filament but should be used with caution, as some solvents can damage the nozzle.

- Combined Cleaning: Combining mechanical and chemical cleaning methods is often the most effective way to clean brass nozzles. For example, you can use a needle to remove loose debris and then soak the nozzle in acetone to dissolve any remaining filament residue.

Cleaning Steel Nozzles

Steel nozzles are more durable than brass nozzles but can be more challenging to clean.

- Mechanical Cleaning: Using a needle or a small wire brush to remove any debris stuck in the nozzle. This method is effective for removing loose debris but may not be suitable for removing hardened filament.

- Heat and Mechanical Cleaning: Heating the nozzle to a high temperature can soften hardened filament, making it easier to remove with a needle or wire brush. This method requires caution, as overheating the nozzle can damage it.

Cleaning Hardened Steel Nozzles

Hardened steel nozzles are the most durable type of nozzle but require specialized cleaning methods.

- Specialized Tools: Using a nozzle cleaning tool specifically designed for hardened steel nozzles. These tools typically use a combination of mechanical and chemical cleaning methods to remove debris and hardened filament.

- Professional Cleaning: If you are unable to clean your hardened steel nozzle using specialized tools, consider sending it to a professional cleaning service. This ensures that your nozzle is cleaned properly and safely without causing any damage.

Cleaning Ruby Nozzles

Ruby nozzles are highly resistant to wear and tear but require careful cleaning to avoid damage.

- Mechanical Cleaning: Using a soft brush or a piece of cloth to remove any debris stuck in the nozzle. Avoid using sharp objects, as they can scratch the ruby surface.

- Chemical Cleaning: Soaking the nozzle in a mild solvent like isopropyl alcohol can dissolve any remaining filament residue. Avoid using strong solvents, as they can damage the ruby surface.

Preventative Measures for Nozzle Clogging

A clean nozzle is crucial for smooth and high-quality 3D prints. However, even with regular cleaning, nozzle clogging can still occur. Implementing preventative measures can significantly reduce the chances of encountering this issue. By taking proactive steps, you can ensure your nozzle remains unclogged, minimizing downtime and maximizing printing efficiency.

Using High-Quality Filament

The quality of your filament plays a significant role in preventing nozzle clogging. Using high-quality filament ensures that it melts smoothly and consistently, reducing the likelihood of particles forming and obstructing the nozzle.

Using low-quality filament can lead to impurities, moisture absorption, and inconsistent melting, all contributing to nozzle clogging.

Adjusting Printing Settings

Optimizing your printer settings can help minimize the chances of nozzle clogging. These settings directly impact the flow of filament through the nozzle, influencing the melting process and the formation of clogs.

- Temperature:Setting the correct temperature for your filament is crucial. If the temperature is too low, the filament may not melt completely, leading to clogging. Conversely, a temperature that’s too high can cause the filament to degrade and create more debris, increasing the risk of clogging.

- Print Speed:Printing too quickly can lead to insufficient melting time, causing filament to solidify prematurely and potentially clog the nozzle. Slower print speeds allow for better filament melting and reduce the chances of clogging.

- Retraction Settings:Retraction settings control how much filament is pulled back into the extruder when the print head moves to a new location. Incorrect retraction settings can cause filament to accumulate at the nozzle tip, leading to clogging. Fine-tuning these settings can help prevent filament buildup.

- Flow Rate:Adjusting the flow rate can also help prevent clogging. A lower flow rate ensures that less filament is pushed through the nozzle, reducing the risk of clogging. However, be cautious, as a flow rate that’s too low can result in under-extrusion, affecting the quality of your prints.

Troubleshooting Nozzle Cleaning Issues

Sometimes, even after trying the cleaning methods mentioned earlier, you might still encounter a stubborn clog in your 3D printer nozzle. Don’t worry, this is common, and there are a few things you can try to address these challenges.

Addressing Common Cleaning Difficulties

Nozzle cleaning can be tricky, and there are some common issues you might face. Let’s look at a few scenarios and how to overcome them.

- Nozzle Not Heating Up:If your nozzle isn’t heating up properly, the cleaning methods won’t be effective. Make sure your printer’s heating element is working correctly. Check the connections, power supply, and the heating element itself. If the heating element is faulty, you’ll need to replace it.

- Filament Not Feeding Properly:A clogged nozzle can sometimes prevent filament from feeding through properly. This could be due to a kink in the filament, a blockage in the filament path, or a faulty extruder. Inspect the filament path for any obstructions, and ensure the extruder is functioning correctly.

- Clogged Nozzle Despite Cleaning:If you’ve tried all the cleaning methods and the nozzle is still clogged, it’s possible the clog is very stubborn or the nozzle itself might be damaged. In this case, you might need to try alternative cleaning methods or consider replacing the nozzle.

Alternative Cleaning Methods for Stubborn Clogs

For those persistent clogs that don’t budge with the usual cleaning methods, here are some alternative approaches you can try:

- Using a Nozzle Cleaning Needle:A specialized nozzle cleaning needle can help dislodge stubborn clogs. These needles are designed to fit snugly inside the nozzle and are typically made of a strong, durable material. Insert the needle carefully into the nozzle, gently pushing and pulling to break up the clog.

Be cautious not to damage the nozzle.

- Soaking the Nozzle:If the clog is particularly stubborn, you can try soaking the nozzle in a solvent like acetone or isopropyl alcohol. Be sure to use a container that won’t be affected by the solvent. Soak the nozzle for a few hours, then carefully clean it with a brush or cloth.

Be extremely cautious when using solvents as they can be harmful if not handled properly.

- Heating the Nozzle:Sometimes, gently heating the nozzle can help soften the clog and make it easier to remove. You can use a heat gun or a soldering iron, but be extremely careful not to overheat the nozzle, as this can damage it.

Advanced Nozzle Cleaning Techniques

Sometimes, standard cleaning methods might not be enough to address stubborn clogs or severe nozzle damage. In such cases, you might need to explore more advanced techniques. These methods can be more involved, but they can effectively revive a heavily clogged or damaged nozzle.

Using a Nozzle Cleaning Kit

Nozzle cleaning kits offer a comprehensive approach to addressing various nozzle issues. These kits typically include a range of tools and materials designed for specific cleaning tasks.

- Nozzle Cleaning Wire:This thin, flexible wire is used to clear blockages within the nozzle opening. It’s usually made of a material like stainless steel or brass.

- Nozzle Cleaning Needle:A fine needle is used to dislodge stubborn particles that might be stuck within the nozzle.

- Nozzle Cleaning Solution:A specialized cleaning solution is designed to dissolve and remove filament residue and other debris.

- Nozzle Cleaning Brush:A small brush helps to remove loose debris and clean the nozzle’s exterior.

When using a nozzle cleaning kit, it’s important to follow the manufacturer’s instructions carefully.

Using excessive force or improper techniques can damage the nozzle.

Cleaning Nozzles with Specific Materials, How to clean the nozzle of a 3d printer

Depending on the type of clog, you can use specific materials to address the problem.

- Isopropyl Alcohol (IPA):IPA is effective in dissolving filament residue and cleaning the nozzle. Soak a cotton swab or a small piece of cloth in IPA and gently wipe the nozzle.

- Acetone:Acetone is a powerful solvent that can effectively remove stubborn clogs. However, it can also damage certain nozzle materials, so it’s essential to use it with caution.

- Wire:A thin wire can be used to dislodge filament pieces or debris that are stuck inside the nozzle. Carefully insert the wire into the nozzle and gently push or twist it to dislodge the blockage.

Nozzle Maintenance and Replacement: How To Clean The Nozzle Of A 3d Printer

Just like any other part of your 3D printer, your nozzle needs regular care and attention to ensure it performs at its best and lasts longer. Neglecting nozzle maintenance can lead to print quality issues, wasted filament, and even damage to your printer.

Nozzle Maintenance Schedule

A regular maintenance schedule can help you avoid major nozzle problems. Here’s a recommended schedule for cleaning and inspecting your nozzle:

- Daily:Before each printing session, visually inspect the nozzle for any signs of clogging or buildup. If necessary, gently wipe the nozzle with a damp cloth to remove any loose debris.

- Weekly:Perform a thorough cleaning of the nozzle using a suitable method based on the type of nozzle and filament you use. This involves removing any accumulated filament residue and ensuring the nozzle tip is free of obstructions.

- Monthly:Inspect the nozzle for any signs of wear or damage, such as scratches, chipping, or deformation. If you notice any significant wear, consider replacing the nozzle.

Nozzle Replacement

Nozzles are consumables, meaning they will eventually wear out or get damaged. Here’s how to determine when to replace your nozzle:

- Visible wear and tear:Signs of wear and tear include scratches, chipping, or deformation of the nozzle tip. This can affect print quality and cause filament to stick to the nozzle.

- Frequent clogging:If you find yourself constantly cleaning or unclogging your nozzle, it’s a sign that the nozzle may be worn out and needs replacing.

- Print quality issues:If you notice consistent print quality problems, such as stringing, under-extrusion, or inconsistent layer adhesion, even after cleaning the nozzle, it could indicate a worn-out nozzle.

FAQ Section

What if I can’t remove the nozzle?

If the nozzle is stuck, try using a wrench or pliers to grip it firmly. Be careful not to damage the nozzle or the heater block. If it’s still stuck, consult your printer’s manual or contact the manufacturer for assistance.

How often should I clean my nozzle?

It’s recommended to clean your nozzle every 10-20 hours of printing, or more frequently if you notice any signs of clogging.

Can I use a wire brush to clean my nozzle?

While a wire brush can be helpful for removing stubborn debris, it’s important to use it carefully to avoid scratching the nozzle’s surface. A soft-bristled brush is generally a safer option.

What if I accidentally break my nozzle?

Don’t worry! You can easily purchase replacement nozzles online or from your local 3D printing store. Just ensure you get the right size and type for your printer.