What is direct to film printing – What is direct-to-film printing? It’s a revolutionary process that bypasses traditional film and directly exposes an image onto a printing plate. This technique, often used in screen printing, offers numerous advantages over traditional methods, including increased efficiency, cost-effectiveness, and a wider range of printing possibilities.

Direct-to-film printing utilizes a specialized film that is exposed to a digital image using a high-resolution laser. The exposed film then serves as a printing plate, transferring the image onto the desired material. This streamlined process eliminates the need for multiple steps and intermediaries, resulting in faster production times and reduced waste.

What is Direct-to-Film Printing?

Direct-to-film (DTF) printing is a digital printing method that creates images directly onto a special film. This film is then used to create screen printing stencils, allowing for the transfer of designs onto various materials like textiles, plastics, and paper.

It’s a versatile and efficient technique commonly used in the apparel, signage, and promotional product industries.

The Process of Direct-to-Film Printing

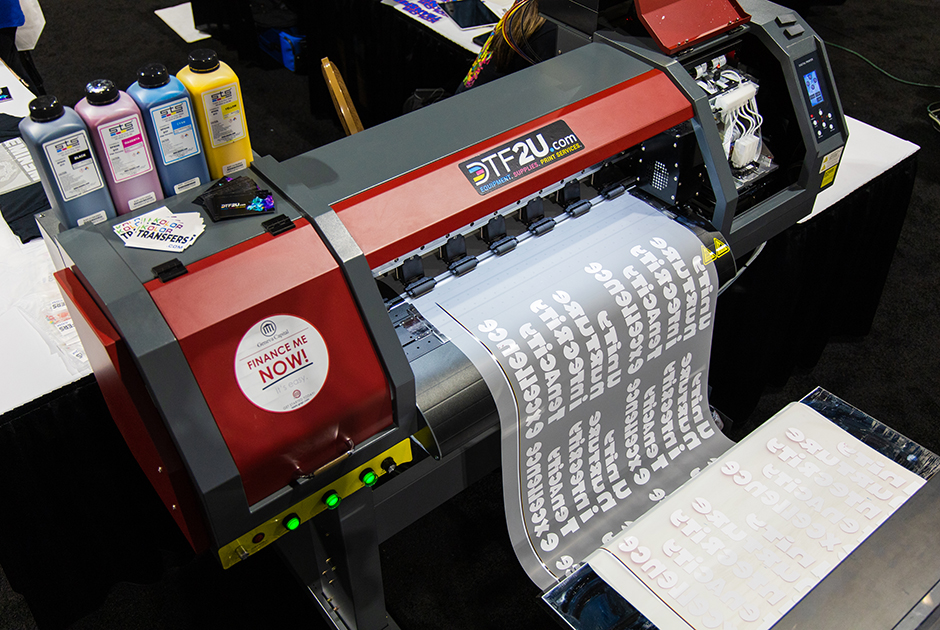

Direct-to-film printing involves a series of steps that combine digital technology and traditional screen printing techniques. The process begins with the creation of a digital design, which is then sent to a specialized printer equipped with a high-resolution inkjet head.

This printer uses UV-curable inks to create the image directly onto a special film, typically a polyester film coated with a light-sensitive emulsion.Once the image is printed onto the film, it is exposed to a UV light source, which hardens the ink and creates a durable stencil.

The exposed film is then washed in a solution that removes the unexposed areas of the emulsion, leaving behind the hardened ink that forms the design. This stencil is then used in a traditional screen printing process to transfer the design onto the desired material.

Materials Used in Direct-to-Film Printing

Direct-to-film printing utilizes several specialized materials to achieve its unique results. * Direct-to-Film (DTF) Film:This is the core material in DTF printing. It’s typically a polyester film coated with a light-sensitive emulsion. This emulsion acts as a barrier, allowing the UV-curable ink to adhere to the film and form a stencil.

UV-Curable Inks

These inks are specially formulated to cure quickly when exposed to UV light. They are available in a wide range of colors and are known for their vibrant and durable properties.

Screen Printing Stencils

These are used to transfer the design from the DTF film onto the final material. They are created by exposing the DTF film to UV light, which hardens the ink and creates a durable stencil.

Comparing Direct-to-Film Printing with Traditional Film Printing

Direct-to-film printing offers several advantages over traditional film printing methods, particularly in terms of efficiency and versatility.

- Faster Production Time:DTF printing eliminates the need for traditional film processing, which can be time-consuming. The entire process, from design creation to stencil production, is significantly faster.

- Increased Detail and Accuracy:The high-resolution inkjet technology used in DTF printing allows for intricate designs with fine details. The precision of the stencil creation process ensures accuracy in transferring the design onto the final material.

- Cost-Effectiveness:DTF printing can be more cost-effective than traditional film printing, especially for small-scale production runs. This is due to the elimination of film processing and the ability to create multiple stencils from a single DTF film.

- Versatility:DTF printing is compatible with a wide range of materials, including textiles, plastics, paper, and even metal. This makes it suitable for various applications, from apparel printing to signage and promotional products.

Creating a Direct-to-Film Print

Here’s a step-by-step guide on how to create a direct-to-film print:

- Design Creation:Start by creating your design using a digital design software. Ensure the design is high-resolution and optimized for DTF printing.

- Film Preparation:Load the DTF film into the specialized printer. The film should be clean and free of any debris.

- Printing the Design:Send the design to the printer, which will use UV-curable inks to create the image directly onto the film.

- Exposure to UV Light:After printing, expose the film to a UV light source. This will harden the ink and create a durable stencil.

- Washing the Film:Wash the exposed film in a solution to remove the unexposed areas of the emulsion. This leaves behind the hardened ink, forming the stencil.

- Screen Printing:Use the DTF film stencil in a traditional screen printing process to transfer the design onto the desired material.

Advantages of Direct-to-Film Printing: What Is Direct To Film Printing

Direct-to-film (DTF) printing offers several advantages over traditional screen printing and digital printing methods. It combines the best aspects of both, resulting in a versatile and efficient printing process that is ideal for a wide range of applications.

Increased Efficiency

DTF printing significantly improves efficiency in printing processes. This is achieved through various aspects of the technology.

- Reduced setup time:DTF eliminates the need for screen creation, which is a time-consuming process in screen printing. This allows for faster turnaround times and reduced production delays, especially for small-batch orders.

- Simplified workflow:The DTF process streamlines the printing workflow, reducing the number of steps involved. This translates to faster production cycles and reduced labor costs.

- Versatility and adaptability:DTF printers can handle various substrates and print designs with intricate details, making them suitable for a wide range of applications. This eliminates the need for multiple printing methods, simplifying production and reducing the risk of errors.

Industries Utilizing DTF Printing

DTF printing has found widespread adoption in various industries due to its efficiency and versatility.

- Apparel and textile printing:DTF is widely used for printing on t-shirts, hoodies, hats, and other garments. Its ability to print on various fabrics and produce high-quality results makes it a popular choice for both small businesses and large-scale apparel manufacturers.

- Promotional products:DTF printing is used to personalize mugs, phone cases, keychains, and other promotional items. Its ability to print on different materials and create intricate designs makes it ideal for creating unique and eye-catching promotional products.

- Sign and display printing:DTF printing is used for creating high-quality signs, banners, and displays. Its ability to produce vibrant colors and sharp details makes it suitable for both indoor and outdoor applications.

Cost-Effectiveness

DTF printing offers cost-effectiveness compared to other printing methods, especially for small-batch orders and personalized products.

- Reduced setup costs:DTF printing eliminates the need for screen creation, which can be expensive, especially for small orders. This makes DTF a more affordable option for businesses that need to print a variety of designs in small quantities.

- Lower printing costs:DTF printing often uses less ink than other printing methods, resulting in lower printing costs per unit. This is especially beneficial for printing on light-colored substrates, where less ink is required to achieve vibrant colors.

- Reduced waste:DTF printing generates less waste than traditional screen printing, as there is no need to create and dispose of screens. This reduces environmental impact and contributes to a more sustainable printing process.

Applications of Direct-to-Film Printing

Direct-to-film (DTF) printing is a versatile technology with a wide range of applications across various industries. It offers several advantages over traditional screen printing, such as its ability to produce high-quality prints on a variety of substrates, its versatility in handling intricate designs, and its cost-effectiveness for small-scale projects.

Applications Across Industries

DTF printing is a valuable tool for various industries, offering specific applications and benefits tailored to their needs. This table highlights some key applications and their advantages in different sectors:| Industry | Specific Applications | Benefits of DTF Printing ||—|—|—|| Apparel & Fashion | T-shirts, hoodies, hats, bags, sportswear, custom apparel, and accessories | High-quality prints with vibrant colors, detailed designs, and soft hand feel, cost-effective for small-scale production runs, and versatility in handling various fabrics || Promotional Products | Mugs, keychains, phone cases, water bottles, and other promotional items | Durable prints, high-resolution graphics, and cost-effectiveness for large-scale promotional campaigns || Signage & Graphics | Posters, banners, window graphics, trade show displays, and vehicle wraps | High-resolution prints, vibrant colors, and durability for outdoor use || Packaging & Labeling | Product labels, boxes, and packaging materials | High-quality prints, intricate designs, and cost-effectiveness for small-scale production runs || Art & Craft | Custom art prints, personalized gifts, and home decor items | High-quality prints, vibrant colors, and versatility in handling various substrates |

Visual Representation of Applications

A flowchart can effectively illustrate the diverse applications of DTF printing: [Flowchart Description]The flowchart starts with a central node labeled “Direct-to-Film Printing”. From this node, branches extend to various industries, such as apparel & fashion, promotional products, signage & graphics, packaging & labeling, and art & craft.

Each branch further divides into specific applications within the respective industries, showcasing the wide range of uses for DTF printing.

Real-World Examples

Here are some real-world examples of how DTF printing has been successfully implemented:

Apparel & Fashion

A small clothing company used DTF printing to create custom t-shirts with intricate designs for a limited-edition collection. The high-quality prints and soft hand feel of the shirts helped the company stand out in the market and increase sales.

Direct to film printing is a method where an image is directly exposed onto a film, skipping the traditional steps of creating a negative. This process can be used to create high-quality prints for a variety of applications, such as advertising and photography.

One thing to consider is how the prints will be organized, and that’s where the concept of “collated print” comes into play. You can learn more about what does collated print mean and how it might impact your direct to film printing needs.

Ultimately, choosing the right printing method depends on the specific project and desired outcome.

Promotional Products

A marketing agency used DTF printing to create personalized water bottles with company logos for a client’s trade show. The durable prints and high-resolution graphics helped the agency make a strong impression on potential clients.

Signage & Graphics

A local business used DTF printing to create eye-catching window graphics for their store. The vibrant colors and high-resolution prints helped attract customers and increase foot traffic.

Packaging & Labeling

A food manufacturer used DTF printing to create unique and informative labels for their new product line. The high-quality prints and intricate designs helped the manufacturer differentiate their products in a crowded market.

Art & Craft

An artist used DTF printing to create custom art prints and personalized gifts for their customers. The vibrant colors and versatility of DTF printing allowed the artist to express their creativity and create unique pieces.

The Future of Direct-to-Film Printing

Direct-to-film printing (DTF) is a relatively new technology that has already made a significant impact on the printing industry. With its numerous advantages, DTF is poised for even greater growth and innovation in the years to come.

Advancements and Innovations in Direct-to-Film Printing Technology

DTF technology is constantly evolving, with advancements being made in areas such as film materials, printing processes, and software.

- Improved Film Materials:Researchers are developing new film materials that offer enhanced durability, flexibility, and resistance to chemicals and scratches. These advancements will lead to longer-lasting films and improved print quality.

- High-Resolution Printing:DTF printers are constantly improving in terms of resolution and print speed. This means that printers can produce even more detailed and intricate designs, further expanding the range of applications for DTF printing.

- Automated Workflows:DTF software is becoming more sophisticated, automating various aspects of the printing process, such as color management, image optimization, and film creation. This automation will streamline workflows and increase efficiency.

Impact of Emerging Technologies on Direct-to-Film Printing

Emerging technologies are poised to have a significant impact on the future of DTF printing.

- Artificial Intelligence (AI):AI can be used to optimize print settings, automate color matching, and even predict potential printing issues. This will further enhance the efficiency and accuracy of DTF printing.

- Internet of Things (IoT):IoT devices can be used to monitor and control DTF printers remotely, enabling real-time data collection and analysis. This will help businesses optimize their printing processes and reduce downtime.

- 3D Printing:DTF printing can be integrated with 3D printing to create custom-designed products with unique textures and finishes. This opens up new possibilities for product personalization and customization.

Future Trends and Challenges Facing the Direct-to-Film Printing Industry, What is direct to film printing

The future of DTF printing presents both opportunities and challenges for the industry.

- Increased Demand for Customization:Consumers are increasingly demanding personalized products, and DTF printing is well-suited to meet this demand. This will drive growth in the DTF printing market.

- Sustainability:The printing industry is facing increasing pressure to adopt more sustainable practices. DTF printing can be made more sustainable by using eco-friendly materials and reducing waste.

- Competition from Other Printing Technologies:DTF printing faces competition from other digital printing technologies, such as direct-to-garment (DTG) printing. To remain competitive, DTF printing companies must continue to innovate and offer unique advantages.

Potential New Applications and Markets for Direct-to-Film Printing

DTF printing is a versatile technology with the potential to be used in a wide range of applications and markets.

- Personalized Apparel:DTF printing is already widely used for printing custom designs on t-shirts, hoodies, and other apparel items. This market is expected to continue to grow as consumers demand more personalized products.

- Promotional Products:DTF printing is ideal for creating promotional products such as tote bags, hats, and keychains. The high-quality prints and durability of DTF make it an excellent choice for promotional items.

- Industrial Applications:DTF printing can be used in industrial applications such as printing circuit boards, labels, and packaging. The precision and durability of DTF printing make it suitable for these demanding applications.

FAQs

What are the limitations of direct-to-film printing?

While direct-to-film printing offers numerous benefits, it does have some limitations. For example, the resolution of the final print is limited by the resolution of the film and the printing process. Additionally, certain types of images, such as those with fine details or complex gradients, may not be suitable for direct-to-film printing.

Is direct-to-film printing suitable for all types of printing?

Direct-to-film printing is primarily used for screen printing applications. It’s particularly well-suited for printing on a variety of surfaces, including textiles, plastics, and paper. However, it may not be suitable for all printing methods, such as offset printing or digital printing on high-gloss paper.

What are the environmental benefits of direct-to-film printing?

Direct-to-film printing can contribute to a more sustainable printing process by reducing waste. The elimination of traditional film and intermediary steps leads to less material consumption and a smaller environmental footprint.