How much is a screen printer? That’s a question many ask when considering this printing method for their projects. Screen printing, a time-honored technique, involves transferring ink through a mesh stencil onto a substrate. It’s a versatile process, used for everything from t-shirts and posters to signage and even electronics.

But the cost of screen printing can vary widely depending on several factors.

This guide delves into the world of screen printing costs, exploring the different types of printers available, the factors influencing their price, and how to find affordable options. We’ll also compare screen printing to other methods and examine future trends shaping this industry.

Types of Screen Printers

Screen printing is a versatile printing method that involves transferring ink through a mesh stencil onto a substrate. This process allows for a wide range of applications, from t-shirts and posters to electronics and medical devices. The type of screen printer you choose will depend on your specific needs, including the size and complexity of your designs, the volume of your production, and the types of materials you will be printing on.

Manual Screen Printers

Manual screen printers are the most basic type of screen printer, and they are often used for small-scale production runs or for hobbyists. These printers are typically hand-operated, and they require the user to manually align the screen, apply ink, and pull the squeegee across the screen.

- Features:Manual screen printers are typically affordable and easy to use, making them a good option for beginners. They are also very versatile and can be used to print on a wide range of materials.

- Capabilities:Manual screen printers are suitable for small-scale production runs and for printing on a variety of materials, including t-shirts, posters, and signs. They are not typically used for high-volume production runs or for printing on delicate materials.

- Typical Applications:Manual screen printers are often used for hobbyists, small businesses, and for printing on promotional materials, such as t-shirts, posters, and signs.

Automatic Screen Printers

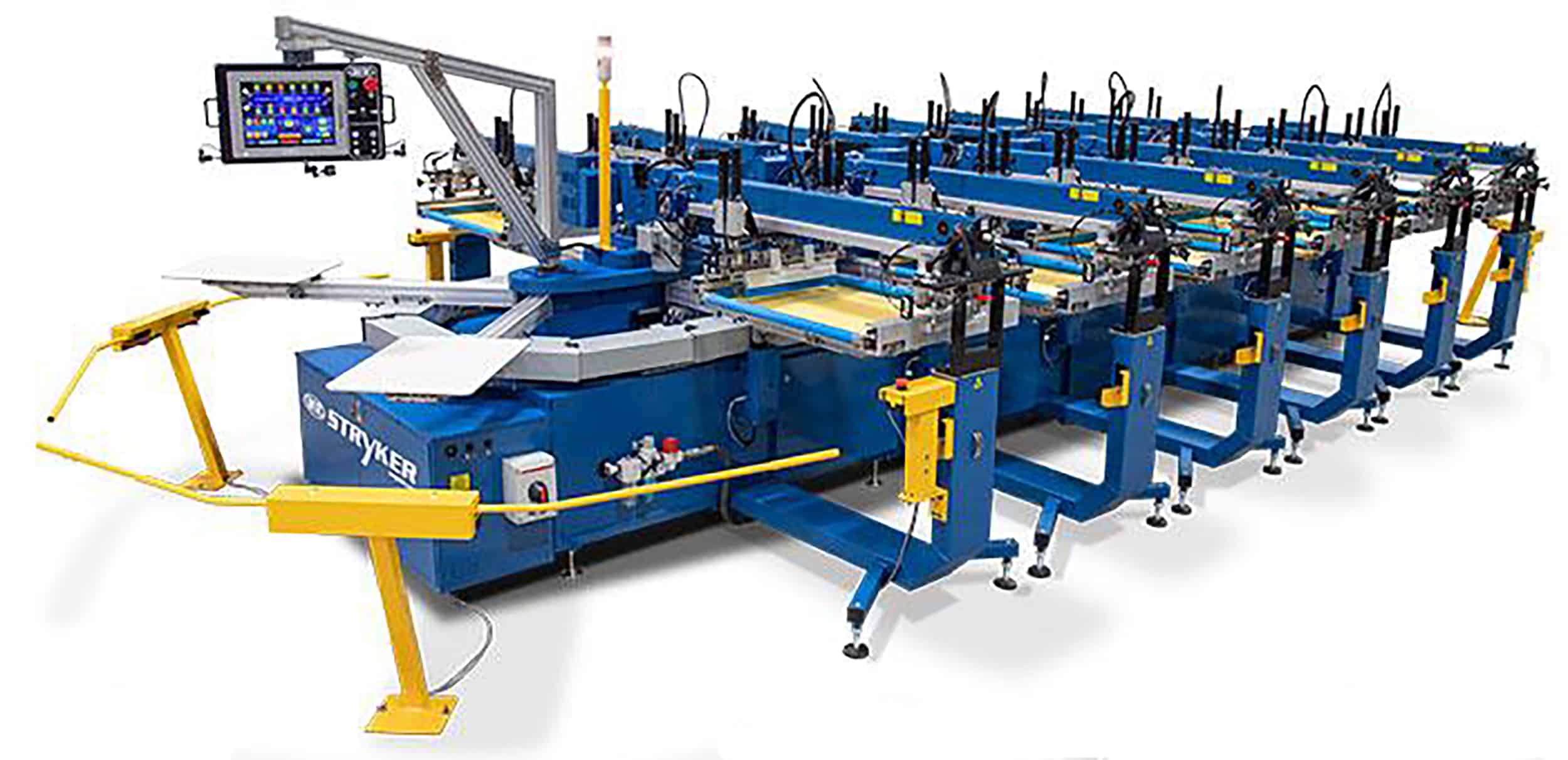

Automatic screen printers are designed for high-volume production runs and offer greater precision and consistency than manual screen printers. These printers use a variety of automated features, such as automatic screen alignment, ink dispensing, and squeegee movement.

- Features:Automatic screen printers offer increased speed, precision, and consistency compared to manual screen printers. They are also typically more expensive than manual screen printers.

- Capabilities:Automatic screen printers are ideal for high-volume production runs and for printing on a variety of materials, including t-shirts, posters, and signs. They are also suitable for printing on delicate materials, such as electronics and medical devices.

- Typical Applications:Automatic screen printers are used by large businesses and manufacturers for high-volume production runs, such as printing on t-shirts, posters, signs, and electronics.

Flatbed Screen Printers

Flatbed screen printers are designed for printing on flat surfaces, such as t-shirts, posters, and signs. These printers use a flat bed to hold the substrate, and the screen is lowered onto the substrate during the printing process.

- Features:Flatbed screen printers are versatile and can be used to print on a variety of materials. They are also relatively easy to use and maintain.

- Capabilities:Flatbed screen printers are suitable for printing on a variety of flat surfaces, including t-shirts, posters, and signs. They are not typically used for printing on cylindrical or curved surfaces.

- Typical Applications:Flatbed screen printers are used for printing on t-shirts, posters, signs, and other flat surfaces.

Rotary Screen Printers

Rotary screen printers are designed for printing on cylindrical or curved surfaces, such as bottles, cans, and tubes. These printers use a rotating cylinder to hold the substrate, and the screen is wrapped around the cylinder during the printing process.

- Features:Rotary screen printers are ideal for printing on cylindrical or curved surfaces. They are also relatively fast and efficient.

- Capabilities:Rotary screen printers are suitable for printing on a variety of cylindrical or curved surfaces, such as bottles, cans, and tubes. They are not typically used for printing on flat surfaces.

- Typical Applications:Rotary screen printers are used for printing on bottles, cans, tubes, and other cylindrical or curved surfaces.

Comparison Table

| Type of Screen Printer | Pros | Cons |

|---|---|---|

| Manual Screen Printer | Affordable, easy to use, versatile | Slow, low production volume, less precise |

| Automatic Screen Printer | Fast, high production volume, precise, consistent | Expensive, complex to operate |

| Flatbed Screen Printer | Versatile, easy to use, relatively inexpensive | Not suitable for cylindrical or curved surfaces |

| Rotary Screen Printer | Ideal for cylindrical or curved surfaces, fast, efficient | Not suitable for flat surfaces, can be expensive |

Factors to Consider When Choosing a Screen Printer

- Production Volume:If you need to print a large number of items, an automatic screen printer is the best option. For smaller production runs, a manual screen printer may be sufficient.

- Substrate:The type of material you will be printing on will also influence your choice of screen printer. For example, if you are printing on t-shirts, a flatbed screen printer is a good option. For printing on bottles, a rotary screen printer is the best choice.

- Design Complexity:If your designs are complex, you may need a screen printer with a higher level of precision. Automatic screen printers offer greater precision than manual screen printers.

- Budget:Screen printers can range in price from a few hundred dollars to tens of thousands of dollars. Consider your budget and the features that are most important to you when making your decision.

Factors Affecting Screen Printer Cost

The cost of a screen printer can vary significantly depending on a range of factors. Understanding these factors is crucial for making an informed purchase decision that aligns with your budget and printing needs.

Brand

The brand of a screen printer is a major factor influencing its cost. Established brands like M&R, Automatic, and Vastex often command higher prices due to their reputation for quality, reliability, and innovation. These brands invest heavily in research and development, resulting in advanced features, durable construction, and excellent customer support.

On the other hand, less known brands may offer more affordable options, but they might compromise on features, build quality, or long-term reliability.

Size

The printing area of a screen printer, often referred to as its “print size,” is directly related to the cost. Larger screen printers, capable of handling larger substrates, naturally require more robust construction and advanced mechanisms, leading to higher prices.

Smaller screen printers, suitable for smaller printing jobs, are typically more affordable.

Features

The features included in a screen printer can significantly impact its price. Features like automatic registration, micro-registration systems, and advanced flash curing units contribute to higher costs. These features enhance printing accuracy, efficiency, and quality. However, basic screen printers with fewer features might be more budget-friendly.

Automation Level

The level of automation in a screen printer also influences its cost. Fully automated screen printers, which handle most tasks independently, offer greater efficiency and precision but come at a premium. Manual screen printers, requiring more human intervention, are generally more affordable.

Price Range

| Screen Printer Category | Price Range ||—|—|| Basic Manual Screen Printers | $1,000

$5,000 |

| Mid-Range Automatic Screen Printers | $5,000

$20,000 |

| High-End Automated Screen Printers | $20,000

$100,000+ |

Screen Printing Costs

Screen printing costs can vary greatly depending on several factors, including the size and complexity of the design, the quantity of prints, the type of ink used, and the overall production process. It’s important to understand the different cost components involved to get a clear picture of what you can expect to pay for your screen printing project.

Breakdown of Screen Printing Costs

Screen printing costs can be broken down into several key components, including equipment, consumables, labor, and overhead.

- Equipment: Screen printing equipment can range in price from a few hundred dollars for basic manual presses to tens of thousands of dollars for automated systems. The cost of equipment will depend on the scale of your operation, the volume of prints you need to produce, and the level of automation you require.

- Consumables: Consumables include items like screens, ink, squeegees, emulsion, and cleaning supplies. The cost of consumables will vary depending on the type and quality of materials used, as well as the size and complexity of your prints.

- Labor: Labor costs include the wages of screen printers, as well as the time spent on design, setup, printing, and finishing. Labor costs can vary depending on the experience and skill level of the printers, as well as the complexity of the printing process.

- Overhead: Overhead costs include rent, utilities, insurance, and other expenses associated with running a screen printing business. Overhead costs can vary depending on the size and location of the business.

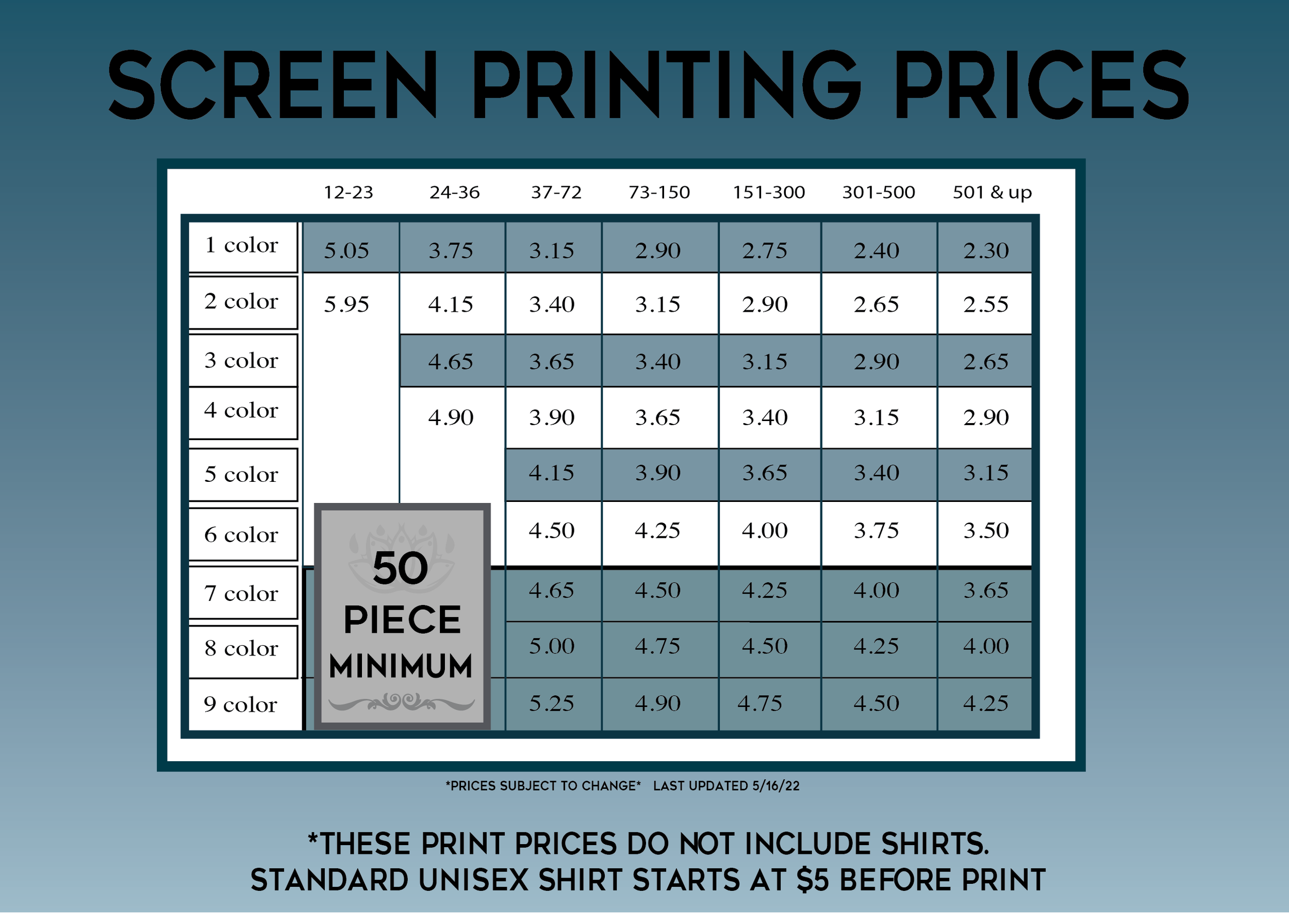

Pricing Structure for Screen Printing Services, How much is a screen printer

Screen printing services are typically priced based on several factors, including the size and complexity of the print, the quantity of prints, and the type of ink used.

- Print Size and Complexity: Larger and more complex prints generally require more ink, time, and effort to produce, which can increase the cost per print.

- Quantity of Prints: The cost per print typically decreases as the quantity of prints increases. This is because the setup costs are spread out over a larger number of prints.

- Type of Ink: The type of ink used can also affect the cost of printing. Specialty inks, such as glow-in-the-dark or metallic inks, can be more expensive than standard inks.

Estimating the Cost of a Screen Printing Project

To estimate the cost of a screen printing project, you can use a simple formula that takes into account the factors mentioned above.

Cost per Print = (Equipment Cost + Consumables Cost + Labor Cost + Overhead Cost) / Quantity of Prints

For example, let’s say you’re planning to print 100 t-shirts with a simple design. You estimate that the equipment cost will be $1000, the consumables cost will be $200, the labor cost will be $500, and the overhead cost will be $

The cost of a screen printer can vary widely, depending on the features and quality you need. If you’re looking for something professional and high-quality, check out don ensor prints , they offer a range of options to suit different budgets.

You’ll also want to consider the type of printing you’ll be doing, as some screen printers are better suited for certain types of materials.

Using the formula above, the cost per print would be:

($1000 + $200 + $500 + $100) / 100 = $18 per print

This is just a rough estimate, and the actual cost may vary depending on the specific details of your project.

Finding Affordable Screen Printing Options

Screen printing can be a great way to create custom apparel, promotional items, and more, but the cost can sometimes be a barrier. Luckily, there are a few affordable options available for those who want to get their screen printing projects done without breaking the bank.

DIY Screen Printing Kits

DIY screen printing kits provide a hands-on and cost-effective way to create custom prints at home. These kits typically include everything you need to get started, such as a screen, emulsion, squeegee, and ink.

Pros

- Cost-effective:DIY kits are generally the most affordable option, as you only need to purchase the kit once.

- Creative control:You have complete control over the design, colors, and printing process.

- Learning experience:It’s a fun and rewarding experience to learn a new skill and create your own prints.

Cons

- Time-consuming:The printing process can be time-consuming, especially for beginners.

- Learning curve:Mastering the techniques and achieving consistent results requires practice and patience.

- Limited scalability:DIY kits are best suited for small-scale projects, as they may not be efficient for large orders.

Online Printing Services

Online printing services offer a convenient and affordable way to get your designs printed on various items, including t-shirts, hoodies, tote bags, and more. These services typically allow you to upload your designs, choose from a variety of printing options, and order your prints online.

Pros

- Convenience:Ordering online is quick and easy, eliminating the need for in-person visits.

- Wide range of options:Many services offer a wide selection of printing options, colors, and apparel styles.

- Competitive pricing:Online services often offer competitive pricing, especially for larger orders.

Cons

Local Print Shops

Local print shops offer personalized service and the opportunity to discuss your project details with a professional. They can provide guidance on design, printing techniques, and material choices.

Pros

- Personalized service:You can get expert advice and assistance from experienced professionals.

- High-quality printing:Local shops often use high-quality equipment and materials, ensuring professional results.

- Local support:You can easily visit the shop for any questions or concerns.

Cons

Tips for Finding Affordable Screen Printing Solutions

- Compare prices:Get quotes from multiple print shops and online services to compare prices and find the best deal.

- Look for discounts:Many print shops and online services offer discounts for bulk orders, student discounts, or special promotions.

- Consider your needs:Determine the quantity, quality, and turnaround time required for your project to choose the most suitable option.

- Read reviews:Check online reviews and testimonials to get an idea of the quality and reliability of different print shops and services.

- Ask for samples:Request samples from potential print shops to assess the quality of their printing and materials.

Screen Printing vs. Other Printing Methods

Screen printing is a versatile and widely used printing technique, but it’s not always the best choice for every project. To determine if screen printing is the right option for you, it’s important to understand its strengths and weaknesses compared to other popular printing methods.

This section will delve into the advantages and disadvantages of screen printing, digital printing, offset printing, and laser engraving, providing insights into their suitability for various printing needs.

Comparison of Printing Methods

The choice of printing method often depends on factors such as budget, quantity, design complexity, and desired quality. Let’s compare the key aspects of each method:

- Screen Printing:

- Advantages:High-quality prints, vibrant colors, durability, cost-effective for large quantities, ideal for textured surfaces, versatile with ink types and colors.

- Disadvantages:Setup costs can be high, not ideal for small runs, limited detail and intricate designs, not suitable for complex gradients or photos.

- Digital Printing:

- Advantages:Low setup costs, fast turnaround times, ideal for small runs, high-resolution prints, suitable for complex designs and photos.

- Disadvantages:Ink may fade over time, less durable than screen printing, limited color options, higher cost per print for large quantities.

- Offset Printing:

- Advantages:High-quality prints, consistent color reproduction, cost-effective for very large quantities, ideal for high-volume publications and packaging.

- Disadvantages:High setup costs, long turnaround times, not suitable for small runs, limited design flexibility.

- Laser Engraving:

- Advantages:Permanent and durable markings, precise detail, suitable for a wide range of materials, ideal for personalization and unique designs.

- Disadvantages:Limited color options, high initial investment, not suitable for large-scale production, may damage delicate materials.

Examples of Suitable Applications

To illustrate the best use cases for each printing method, let’s consider some real-world scenarios:

- Screen Printing:Ideal for producing large quantities of t-shirts, posters, banners, and promotional materials. It’s also suitable for printing on textured surfaces like canvas bags and tote bags.

- Digital Printing:Perfect for small-scale projects like business cards, flyers, brochures, and personalized invitations. It’s also commonly used for printing on demand and short-run photo books.

- Offset Printing:The preferred choice for high-volume printing projects like magazines, newspapers, books, and packaging materials. It’s also cost-effective for large-scale marketing campaigns.

- Laser Engraving:A popular choice for personalizing items like trophies, awards, jewelry, and gifts. It’s also used for creating custom signage, industrial marking, and creating intricate designs on wood, metal, and plastic.

Future Trends in Screen Printing: How Much Is A Screen Printer

Screen printing, a time-honored printing method, is constantly evolving, embracing innovative technologies and adapting to changing demands. The future of screen printing promises exciting advancements, shaping the industry in ways that enhance efficiency, sustainability, and creativity.

Emerging Technologies in Screen Printing

The integration of cutting-edge technologies is poised to revolutionize the screen printing process. These advancements offer opportunities for increased precision, automation, and eco-friendly practices.

- 3D Printing: 3D printing, also known as additive manufacturing, is making its mark in screen printing by creating custom-designed screens with intricate patterns and complex geometries. This technology enables the production of highly detailed and unique designs, opening doors to personalized and bespoke printing solutions.

For example, 3D-printed screens can be used to create intricate patterns on textiles, resulting in unique and visually stunning designs that were previously difficult to achieve.

- Automated Systems: Automation is transforming the screen printing process, streamlining production and enhancing efficiency. Automated screen printing machines can handle tasks like screen preparation, ink application, and curing, reducing manual labor and minimizing human error. This increased automation allows for faster production times and consistent print quality, making screen printing more accessible to businesses of all sizes.

- Eco-Friendly Inks: The screen printing industry is actively seeking sustainable solutions, and the development of eco-friendly inks is a significant step in this direction. These inks are made from renewable resources, biodegradable materials, and non-toxic pigments, minimizing environmental impact. The use of eco-friendly inks not only reduces pollution but also caters to the growing consumer demand for sustainable products.

For instance, water-based inks are increasingly popular due to their low VOC emissions and ability to be cleaned with water, reducing the use of harsh chemicals and minimizing environmental impact.

FAQ

What are the main types of screen printers?

Screen printers come in various types, including manual, semi-automatic, and fully automatic. Manual printers are affordable but require more labor, while automated printers offer high speed and efficiency but come at a higher cost.

How much does a basic screen printer cost?

Basic manual screen printers can be found for under $1000, while more advanced models can cost upwards of $10,000.

What are the common consumables used in screen printing?

Common consumables include inks, screens, squeegees, and emulsion.

Can I screen print at home?

Yes, you can find DIY screen printing kits that are affordable and easy to use.