Can the p1s print 45 deg overhangs – Can the P1S print 45-degree overhangs? This question pops up frequently among 3D printing enthusiasts, especially those looking to create intricate designs with complex geometries. Overhangs, those sections of a print that extend horizontally without support, present a unique challenge for 3D printers.

The P1S, with its advanced features and printing capabilities, has proven itself a capable machine for various projects. But can it handle the demands of overhang printing, specifically at the challenging 45-degree angle? Let’s dive into the details and see what we can discover.

This article will explore the intricacies of overhang printing, specifically focusing on the P1S 3D printer’s capabilities and limitations in achieving successful 45-degree overhangs. We’ll examine the factors influencing overhang printing quality, including support structures, printing parameters, and material choices.

Additionally, we’ll provide practical tips and techniques to optimize your P1S for overhang printing, along with a simple test model to evaluate its performance.

Understanding Overhangs in 3D Printing: Can The P1s Print 45 Deg Overhangs

Overhangs are a fundamental aspect of 3D printing, referring to features that extend horizontally beyond the supporting structure, defying gravity. They are common in various designs, adding complexity and posing challenges to the printing process.

Challenges Associated with Printing Overhangs

Overhangs present significant challenges for 3D printers due to the inherent limitations of the technology. The primary challenge lies in the lack of support for these features, as the printed material tends to droop or sag under its own weight.

This can lead to various printing defects, including:

- Sagging:Overhangs, especially those with large angles, can sag under their own weight, resulting in distorted or uneven features.

- Layer Delamination:The lack of support can cause layers to detach from each other, leading to gaps or holes in the printed object.

- Unsupported Structures:Overhangs exceeding a certain angle require additional support structures, which can be challenging to remove without damaging the printed object.

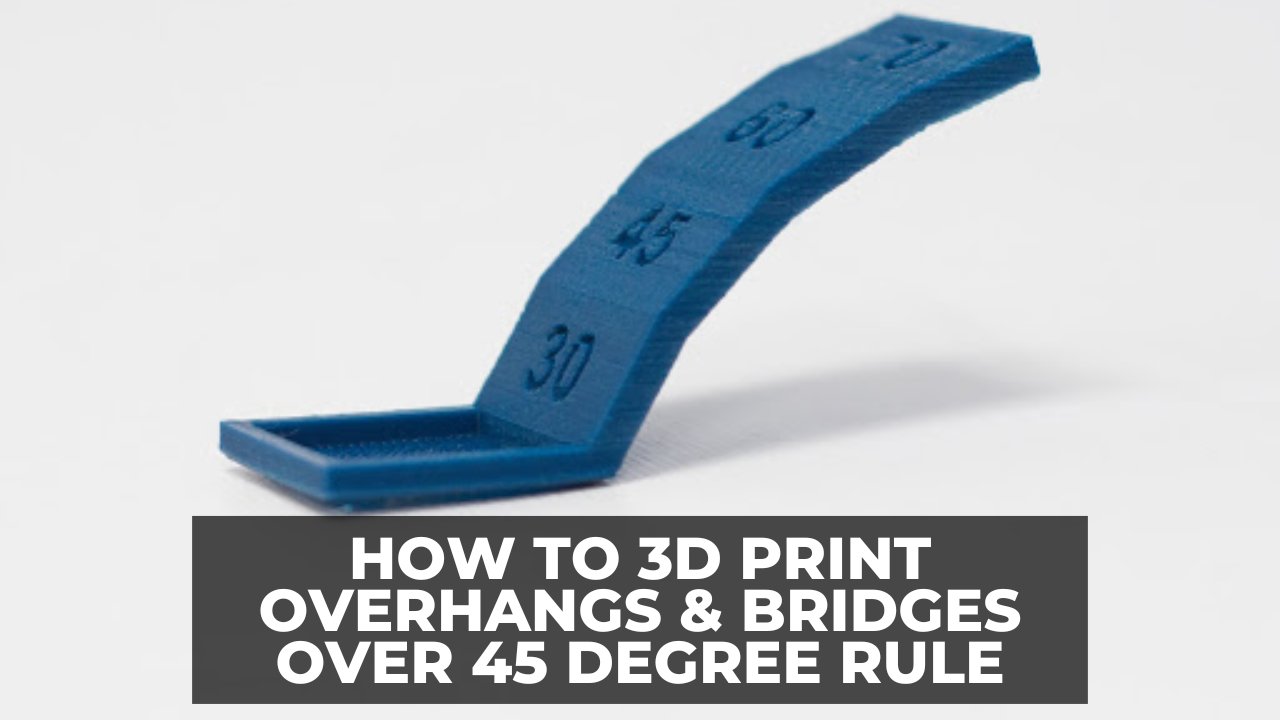

Common Overhang Angles

Overhang angles are commonly classified based on their degree of horizontal extension. The angle is measured from the horizontal plane, with 0 degrees representing a completely flat surface and 90 degrees representing a vertical wall. Here are some common overhang angles encountered in 3D printing:

- 0-45 degrees:These overhangs are generally considered manageable for most 3D printers, especially with appropriate printing settings and supports.

- 45-60 degrees:Overhangs within this range can be more challenging, requiring careful consideration of support structures and printing settings.

- 60-90 degrees:Overhangs beyond 60 degrees pose significant challenges and often require specialized printing techniques or additional supports.

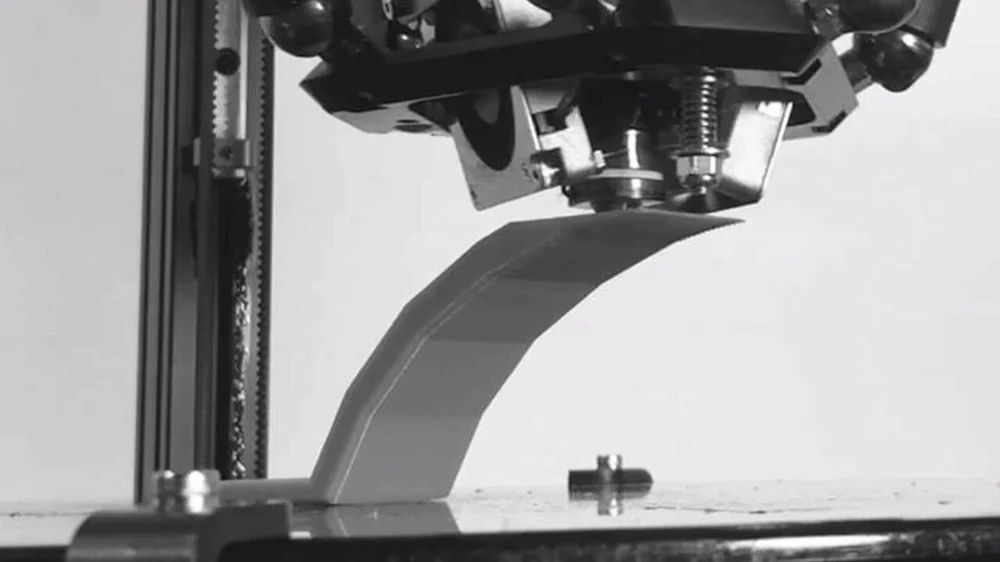

P1S 3D Printer Capabilities

The P1S 3D printer is a popular choice for hobbyists and professionals due to its affordability and user-friendliness. It offers a balance of features and capabilities, making it suitable for a wide range of projects. This section will explore the P1S’s key features, its printing technologies, and its strengths and limitations, particularly in the context of printing overhangs.

Printing Technologies Used by the P1S

The P1S employs Fused Deposition Modeling (FDM) technology, a common and versatile method for 3D printing. In FDM, a thermoplastic filament is heated and extruded through a nozzle, layer by layer, to build up a 3D object.The P1S uses a Bowden-style extruder, where the filament is fed through a tube to the nozzle, allowing for a more compact printer design.

Overhang Printing Capabilities of the P1S

The P1S, like most FDM printers, has limitations when it comes to printing overhangs. Overhangs are sections of a print that extend beyond the support structure, requiring additional support material to prevent sagging or collapse during printing. The P1S’s ability to print overhangs depends on several factors, including:

- Nozzle Size:A smaller nozzle size generally results in better overhang quality, as it allows for finer control over the filament deposition.

- Printing Speed:Slower printing speeds provide more time for the filament to cool and solidify, improving overhang stability.

- Printing Temperature:The filament’s melting temperature plays a crucial role in overhang quality. A slightly higher temperature can help to improve layer adhesion, but excessive heat can lead to drooping or sagging.

- Support Material:Using support material is essential for printing overhangs. The P1S can use soluble support material, which can be easily removed after printing, or standard support material, which needs to be manually removed.

While the P1S can handle overhangs with careful settings and support structures, it’s important to note that very large or complex overhangs may require specialized printing techniques or post-processing to achieve satisfactory results.

Factors Affecting Overhang Printing Success

Printing overhangs successfully in 3D printing requires careful consideration of several factors that can influence the quality of the print. Understanding these factors and adjusting printing parameters accordingly is crucial for achieving desired results.

Role of Support Structures

Support structures are essential for overhang printing, especially for angles exceeding 45 degrees. They act as temporary scaffolding, providing a solid base for the overhang to solidify and prevent sagging or drooping. Support structures are typically printed in a sacrificial material that is easily removed after the print is complete.

Support structures are essential for overhang printing, especially for angles exceeding 45 degrees.

Impact of Printing Parameters, Can the p1s print 45 deg overhangs

Printing parameters play a crucial role in determining the quality of overhang prints. Adjusting these parameters can significantly improve the strength and appearance of overhangs.

So, you’re wondering if your P1S can handle those 45-degree overhangs, right? It’s all about the printer’s capabilities and the material you’re using. Speaking of materials, you might be interested in learning whether you can print on cardstock with your Brother JF335DW.

You can find out more about that here. Once you’ve got the right paper, you can experiment with different settings to see if your P1S can print those overhangs without any issues.

Layer Height

Lower layer heights (e.g., 0.1mm) result in smoother overhangs with less visible layer lines. However, lower layer heights increase print time. Higher layer heights (e.g., 0.2mm) can be used for less demanding overhangs, but may result in visible layer lines.

Infill Density

Infill density affects the strength and weight of the overhang. Higher infill densities (e.g., 50-100%) provide greater strength and stability for overhangs. Lower infill densities (e.g., 10-20%) are suitable for less demanding overhangs.

Printing Speed

Printing speed can impact the quality of overhangs. Slower printing speeds allow the material to cool and solidify more effectively, reducing the risk of sagging. Faster printing speeds may result in less stable overhangs, especially for larger overhangs.

Types of Materials for Overhang Printing

The choice of material plays a significant role in overhang printing success. Some materials are more suitable for overhangs than others.

Thermoplastics

Thermoplastics are commonly used in 3D printing, and some are particularly well-suited for overhang printing.

- ABS(Acrylonitrile butadiene styrene): ABS is a strong, durable thermoplastic with good overhang printing properties. It is often used for functional parts and prototypes.

- PLA(Polylactic acid): PLA is a biodegradable thermoplastic with good overhang printing properties. It is often used for prototypes, toys, and decorative items.

- PETG(Polyethylene terephthalate glycol): PETG is a strong, durable thermoplastic with good overhang printing properties. It is often used for functional parts, prototypes, and bottles.

Photopolymers

Photopolymers are materials that solidify when exposed to light. They are commonly used in resin 3D printers and can achieve excellent overhang printing results.

- Resin: Resin-based photopolymers offer excellent detail and smooth surfaces, making them ideal for intricate overhangs.

Techniques for Improving Overhang Printing with the P1S

The P1S, while capable of printing overhangs, can benefit from optimization for achieving clean, strong, and detailed overhangs. Here’s a guide to configuring your P1S for improved overhang printing.

Configuring the P1S for Optimal Overhang Printing

To achieve optimal overhang printing with your P1S, follow these steps:

- Adjust Print Settings:Experiment with print settings such as layer height, infill density, and print speed. Lower layer heights (e.g., 0.1mm or 0.15mm) and higher infill densities (e.g., 50% or more) generally provide better support for overhangs. Lowering print speed can also help improve overhang quality by allowing the filament to solidify properly.

- Use a Raft or Brim:A raft or brim provides a larger base area for your print, which can help to prevent overhangs from warping or detaching during printing. Rafting adds a sacrificial layer beneath your model, while a brim creates a wider base around your model.

- Enable Retraction:Retraction helps to prevent stringing and oozing, which can affect overhang quality. Ensure that retraction is enabled in your slicer settings and adjust the retraction distance and speed based on your filament and printer.

- Optimize Cooling:Adequate cooling helps to solidify the filament quickly, which is essential for maintaining overhang integrity. Ensure that your P1S has sufficient cooling fans and that they are functioning properly. Consider adding a dedicated cooling fan to your print head for better results.

Using Support Structures

Support structures play a crucial role in ensuring the success of overhang printing. They provide temporary support for overhanging sections, preventing them from sagging or collapsing during printing. The P1S offers various support structure options in its slicer software:

- Standard Supports:These are the default support structures generated by the slicer. They provide basic support and are generally sufficient for most overhangs. However, they may leave noticeable marks on your print.

- Tree Supports:Tree supports are designed to be more aesthetically pleasing and leave minimal marks on your print. They consist of thin, branching supports that extend from the build platform to the overhanging sections.

- Custom Supports:You can create custom support structures by manually defining their placement and orientation. This allows for greater control over support generation and can help to minimize support artifacts on your print.

Tips and Tricks for Clean Overhangs

Here are some additional tips and tricks for achieving clean, strong overhangs with the P1S:

- Use a High-Quality Filament:Filament with good flow properties and high tensile strength is essential for overhang printing. Consider using filaments specifically designed for overhangs, such as PLA+ or PETG.

- Reduce Print Speed for Challenging Overhangs:For particularly challenging overhangs, consider further reducing your print speed to allow for better filament solidification.

- Adjust Z-Offset:Fine-tuning your Z-offset can help to prevent overhangs from detaching or warping. Experiment with small adjustments to find the optimal setting for your print.

- Clean the Print Bed:A clean print bed ensures good adhesion, which is crucial for overhang printing. Clean your print bed regularly with a soft cloth and isopropyl alcohol.

- Use a Heated Bed:A heated bed can help to improve adhesion and prevent warping, particularly for materials like ABS and Nylon.

- Experiment with Different Slicer Settings:Explore different slicer settings and experiment with different combinations to find the optimal settings for your specific model and overhangs.

Evaluating Overhang Printing Results

To determine the P1S’s capability in printing 45-degree overhangs, a simple test model can be designed and printed. This model allows you to assess the quality of the printed overhangs and understand the P1S’s limitations.

Designing a Test Model

A simple test model for evaluating 45-degree overhang printing can be designed using a 3D modeling software like Tinkercad or Fusion 360. The model should consist of a base and a series of overhangs extending from the base at a 45-degree angle.

The overhangs should vary in length to assess the P1S’s ability to print overhangs of different lengths. For instance, the model could include overhangs with lengths ranging from 5mm to 20mm. This provides a visual representation of the P1S’s performance across different overhang lengths.

Evaluating Overhang Quality

The quality of the printed overhangs can be assessed based on several criteria:

Surface Finish

The surface finish of the printed overhangs should be smooth and free from noticeable defects, such as layer lines, gaps, or warping. This can be visually assessed and, if necessary, magnified using a magnifying glass or microscope. A smoother surface finish generally indicates better overhang printing performance.

Strength

The strength of the printed overhangs can be evaluated by gently bending or twisting them. The overhangs should be able to withstand a reasonable amount of stress without breaking or cracking. A strong overhang suggests good adhesion between layers, which is crucial for overhang printing.

Accuracy

The accuracy of the printed overhangs can be assessed by measuring their dimensions and comparing them to the design specifications. The overhangs should be printed within a reasonable tolerance, typically within a few tenths of a millimeter.

Limitations of the P1S in Overhang Printing

While the P1S can print overhangs, it may encounter limitations depending on the overhang length and printing settings. These limitations can include:

Sagging

Longer overhangs can sag due to their weight, leading to distorted shapes and reduced accuracy.

Layer Delamination

Poor adhesion between layers can lead to delamination, especially for overhangs with larger angles.

Print Failures

In some cases, the P1S may not be able to successfully print long overhangs, leading to print failures or incomplete prints.

Potential Solutions

Several techniques can be employed to improve the quality of overhang printing with the P1S:

Support Structures

Using support structures can help to prevent sagging and layer delamination by providing additional support for the overhangs.

Slower Print Speeds

Reducing the print speed can allow the plastic to cool and solidify more effectively, improving layer adhesion and reducing sagging.

Higher Temperatures

Increasing the nozzle temperature can improve the flow of the filament, leading to better layer bonding and reduced delamination.

Retraction Settings

Optimizing retraction settings can help to minimize stringing and oozing, which can affect the quality of overhangs.

Print Orientation

Printing overhangs in a different orientation can sometimes improve their quality by minimizing the amount of unsupported material.

Common Queries

What is the maximum overhang angle the P1S can print without support?

The P1S can typically print overhangs up to around 45 degrees without support, but the actual angle depends on factors like print speed, layer height, and filament type.

Are there any specific support materials recommended for P1S overhang printing?

While the P1S can use various support materials, soluble supports like PVA are generally preferred for overhang printing as they dissolve easily in water, leaving a clean print.

How can I improve the surface finish of overhangs printed on the P1S?

To enhance surface finish, consider using a lower layer height, reducing print speed, and ensuring proper bed adhesion. You can also experiment with different infill densities to find what works best for your specific project.