How do you keep printer ink from drying out? It’s a common question that plagues many printer owners, especially those who don’t use their printers frequently. The science behind ink drying is fascinating, involving a complex interplay of evaporation, oxidation, and ink composition.

Understanding these factors is crucial to preventing ink from drying out in both unused cartridges and printers.

Ink drying is a natural process, but it can be slowed down or even prevented with the right techniques. From proper storage conditions for ink cartridges to regular printer maintenance, there are numerous strategies you can employ to keep your ink fresh and your printer running smoothly.

Let’s delve into the details and discover how to extend the life of your printer ink.

Understanding Ink Drying: How Do You Keep Printer Ink From Drying Out

Ink drying is a complex process that involves a combination of physical and chemical changes. Understanding how ink dries is crucial for maintaining the quality and longevity of your printed documents.

Evaporation

Evaporation is the primary driving force behind ink drying. It involves the transition of the liquid solvent in the ink from a liquid state to a gaseous state. The rate of evaporation is influenced by several factors, including temperature, humidity, and the type of solvent used.

As the solvent evaporates, the ink becomes more viscous, which means it becomes thicker and less fluid. This increased viscosity helps to slow down the ink flow and prevent it from spreading or bleeding on the paper.

Oxidation

Oxidation is a chemical process that involves the reaction of ink components with oxygen in the air. This reaction can lead to the formation of solid polymers, which contribute to the solidification of the ink. The rate of oxidation can vary depending on the ink composition, temperature, and humidity.

Oxidation plays a crucial role in the drying process, particularly for inks that contain unsaturated oils or resins. These inks often dry through a process called “polymerization,” where the molecules of the oil or resin react with oxygen to form a solid, cross-linked network.

Evaporation and Oxidation Interplay

Evaporation and oxidation often work together to achieve ink drying. Evaporation removes the solvent, allowing the ink to become more viscous and concentrated. This increased concentration facilitates the chemical reactions involved in oxidation, leading to the formation of solid polymers.

The interplay between evaporation and oxidation is essential for achieving a smooth, even ink film that adheres well to the paper surface.

Factors Affecting Ink Drying Time

Several factors can influence the rate at which ink dries. These factors include:

Temperature

Higher temperatures accelerate the rate of evaporation, leading to faster drying times. This is because increased temperature provides more energy to the solvent molecules, enabling them to escape from the liquid phase more readily.

Humidity

Humidity can affect ink drying in two ways. High humidity can slow down the evaporation rate, as the air is already saturated with moisture, making it harder for the solvent to evaporate. Conversely, low humidity can accelerate evaporation, resulting in faster drying times.

However, low humidity can also lead to ink smearing, as the ink may dry too quickly before it has had a chance to properly settle on the paper.

Ink Composition

The composition of the ink plays a significant role in determining its drying characteristics. Different inks contain different types of solvents, pigments, and additives, which can affect the evaporation rate, oxidation rate, and overall drying time.

- Solvents:The type of solvent used in the ink can have a significant impact on drying time. For example, water-based inks typically dry faster than oil-based inks because water evaporates more readily than oil.

- Pigments:The pigments used in the ink can also affect drying time. Some pigments, such as carbon black, can slow down the drying process because they can absorb the solvent and prevent it from evaporating quickly.

- Additives:Additives are added to inks to improve their performance characteristics, such as drying time, flow, and adhesion. For example, some additives can act as drying agents, accelerating the evaporation process.

Ink Types and Drying Characteristics

Inks can be broadly classified based on their drying mechanisms. Some common types of inks include:

Water-Based Inks

Water-based inks are the most common type of ink used in inkjet printers and some fountain pens. They consist of pigments or dyes suspended in water, with additives to improve their flow and drying characteristics. Water-based inks typically dry quickly, within a few seconds, due to the rapid evaporation of water.

Keeping your printer ink from drying out is essential, especially if you’re a fan of high-quality prints. If you’re looking for some stunning artwork to showcase, you might want to check out don troiani prints for sale , which are sure to be a conversation starter.

And once you’ve got your prints, remember to use them regularly to prevent the ink from drying up!

However, they can be susceptible to smearing if they are not allowed to dry completely before being handled.

Oil-Based Inks

Oil-based inks are used in some ballpoint pens, felt-tip pens, and printing presses. They are composed of pigments or dyes suspended in oil, typically linseed oil or soybean oil. Oil-based inks dry slower than water-based inks, typically taking several minutes to dry.

This is because oil evaporates more slowly than water. Oil-based inks are known for their permanence and resistance to fading.

Solvent-Based Inks

Solvent-based inks are used in some printing presses and art supplies. They consist of pigments or dyes suspended in a solvent, such as alcohol or acetone. Solvent-based inks dry quickly due to the rapid evaporation of the solvent. They are known for their bright colors and high-gloss finish.

However, solvent-based inks can be toxic and may require special handling.

Key Factors Influencing Ink Drying Time

The drying time of an ink is influenced by a complex interplay of factors, including the evaporation rate of the solvent, the oxidation rate of the ink components, and the composition of the ink. The rate of evaporation is affected by temperature, humidity, and the type of solvent used.

Oxidation is influenced by the ink composition, temperature, and humidity. The composition of the ink, including the types of solvents, pigments, and additives, plays a crucial role in determining its drying characteristics. Understanding these factors can help you optimize ink drying time and ensure the quality of your printed documents.

Preventing Ink Drying in Cartridges

Now that we understand how ink dries, let’s dive into the practical strategies to prevent this from happening to your precious ink cartridges. By implementing the following tips, you can significantly extend the lifespan of your cartridges and ensure your printer is ready to go when you need it.

Storage Conditions for Unused Ink Cartridges

The environment where you store your unused ink cartridges plays a crucial role in preventing ink drying. Here’s a breakdown of the key factors:

- Temperature:Ideal storage temperatures for ink cartridges range from 59°F to 77°F (15°C to 25°C). Storing cartridges in extreme temperatures, whether too hot or too cold, can accelerate ink drying and degrade its quality. Room temperature is generally a good choice, avoiding direct exposure to heat sources like radiators or sunlight.

- Humidity:Humidity levels can also impact ink drying. While excessive humidity can promote mold growth, low humidity can lead to ink drying out. Maintaining a moderate humidity level, between 40% and 60%, is recommended for optimal ink cartridge storage.

- Light Exposure:Direct sunlight or fluorescent light can break down ink pigments, leading to color fading and reduced print quality. It’s best to store cartridges in a dark or dimly lit area, away from direct light sources.

- Position:Storing ink cartridges upright is generally recommended, as this helps prevent ink from settling and potentially clogging the printhead. However, some cartridges may have specific instructions from the manufacturer regarding storage position, so always refer to the manufacturer’s guidelines.

Storage Duration

While proper storage conditions can significantly extend the lifespan of your ink cartridges, there are limitations to how long you can store them before potential drying occurs.

- Recommended Timeframes:Ink cartridges typically have a shelf life of around 1 to 2 years, but this can vary depending on the ink type and cartridge design. For example, dye-based inks tend to have a shorter shelf life than pigment-based inks, which are more resistant to drying.

- Factors Affecting Storage Duration:Several factors can influence the storage duration of ink cartridges, including the ink type, cartridge design, and storage conditions. For instance, cartridges with a tightly sealed design and high-quality ink formulations tend to have longer shelf lives. Conversely, cartridges with loose seals or air vents are more susceptible to ink drying.

Ink Cartridge Protectors

To further protect your ink cartridges from drying out, consider using protectors designed specifically for this purpose.

- Types of Protectors:Several types of ink cartridge protectors are available, including seals, caps, and airtight containers. Seals are typically adhesive strips that cover the ink cartridge opening, creating a barrier against air exposure. Caps are small, reusable covers that fit over the cartridge opening, providing a similar function.

Airtight containers are sealed containers designed to hold multiple cartridges, creating a controlled environment to prevent drying.

- Benefits:Using protectors offers several benefits, including reducing air exposure to the ink, controlling moisture levels, and preventing dust and debris from contaminating the cartridge.

- Application:Always follow the manufacturer’s instructions for applying and using ink cartridge protectors. Ensure the protector is properly sealed and that the cartridge is stored in a suitable environment.

High-Quality Ink Cartridges

The quality of the ink cartridge itself can also play a significant role in preventing ink drying.

- Ink Formulation:The ink formulation used in cartridges can impact their drying tendencies. High-quality inks often contain special additives that help prevent drying and maintain their flow properties.

- Cartridge Design:The design of the ink cartridge can also contribute to ink freshness. Cartridges with tightly sealed openings, air vents that minimize air exposure, and internal seals that prevent ink from evaporating are less likely to dry out.

- Brand Reputation:Reputable ink cartridge manufacturers invest in high-quality materials and manufacturing processes, resulting in cartridges that are less prone to ink drying. Look for brands known for their reliability and durability.

Preventing Ink Drying in Printers

While keeping ink from drying in cartridges is crucial, it’s equally important to address ink drying within the printer itself. This involves understanding the printer’s internal mechanisms and adopting preventative measures to ensure smooth ink flow and prevent clogging.

Printer Maintenance Tips

Regular maintenance is key to preventing ink drying in your printer. Here are some tips to consider:

| Tip | Description |

|---|---|

| Regular Use | The best way to prevent ink drying is to use your printer frequently. Even printing a simple test page once a week can help keep the ink flowing. |

| Printer Maintenance Routine | Most printers have a built-in cleaning routine. Run this routine periodically to clear any dried ink from the printhead. |

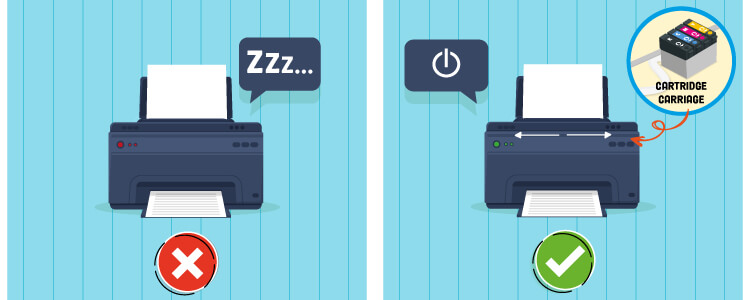

| Proper Shutdown | Always turn off your printer using the power button. Avoid simply unplugging it, as this can damage the printer and potentially lead to ink drying. |

Printer Head Cleaning

Performing a printer head cleaning routine is essential for preventing ink clogging and drying. This process involves flushing the printhead with cleaning solution to remove any dried ink buildup.

Most printers have a built-in cleaning function that can be accessed through the printer’s control panel or software. The cleaning process typically involves several cycles of ink flushing and nozzle checks. If your printer doesn’t have a built-in cleaning function, you can purchase a dedicated printer head cleaning solution and follow the instructions provided by the manufacturer.

Using the Correct Ink

Using the correct type of ink for your printer model is crucial for optimal performance and preventing ink drying. Each printer model is designed to work with specific ink formulations that are compatible with its printhead and ink delivery system.

Using incompatible inks can lead to several issues, including:

- Clogged printheads

- Poor print quality

- Damaged printer components

- Voiding the printer warranty

Always refer to your printer’s manual or the manufacturer’s website to identify the correct ink cartridges for your model. Using genuine OEM (Original Equipment Manufacturer) ink cartridges is generally recommended, as they are specifically designed for your printer and are less likely to cause issues.

Dealing with Dried Ink

Dried ink in your printer can be a frustrating problem, leading to blurry prints, streaks, and even complete print failures. While prevention is key, sometimes you need to tackle dried ink head-on. Here’s a guide to help you clean your printer and get back to printing smoothly.

Manual Cleaning Techniques

Manual cleaning methods are often the first line of defense against dried ink. These techniques involve physically removing the dried ink from the printer nozzles using readily available tools.

- Using a cotton swab and isopropyl alcohol: This is a common and effective method for removing dried ink from printer nozzles.

- Use 99% isopropyl alcohol, as it evaporates quickly and leaves minimal residue.

- Dampen a cotton swab with the alcohol, being careful not to saturate it.

- Gently wipe the printer nozzles with the swab, moving in a single direction to avoid spreading the ink.

- Avoid excessive pressure, as it could damage the printer head.

- Be cautious not to touch any sensitive parts of the printer with the swab.

- Using a syringe and cleaning solution: This method is particularly useful for stubborn ink clogs.

- Fill a syringe with a specialized cleaning solution designed for your printer ink type.

- Carefully inject the solution into the printer nozzles, allowing it to soak for the recommended time (usually 5-10 minutes).

- After soaking, remove the solution from the nozzles using a clean syringe or by gently blotting with a tissue.

- Dry the nozzles thoroughly with a clean, dry cloth or by allowing them to air dry.

- Using a needle and thread: This method is a last resort for extremely stubborn clogs and should be used with extreme caution.

- Use a very fine needle and a piece of thread, preferably nylon or silk.

- Carefully insert the needle into the nozzle, using the thread to gently dislodge the dried ink.

- Avoid using excessive force, as it could damage the printer head.

- This method is not recommended for all printer models, as some printer heads are delicate and easily damaged.

Specialized Cleaning Solutions

Specialized cleaning solutions are formulated to effectively dissolve and remove dried ink from printer nozzles. The type of cleaning solution you use depends on the type of ink in your printer.

- Dye-based inks: Dye-based inks are typically water-based and can be cleaned with water-based cleaning solutions.

- Commonly used solutions include distilled water, alcohol-based solutions, and commercial cleaning solutions specifically designed for dye-based inks.

- When choosing a cleaning solution, ensure it is compatible with your printer model and ink type.

- Pigment-based inks: Pigment-based inks are more durable and often require stronger cleaning solutions.

- Specialized cleaning solutions designed for pigment-based inks are typically alcohol-based or solvent-based.

- These solutions are formulated to break down the pigment particles and effectively remove dried ink from the nozzles.

- Other ink types: Specialized cleaning solutions are also available for less common ink types, such as sublimation inks and UV-curable inks.

- These solutions are specifically formulated to address the unique properties of these ink types.

- It’s crucial to use cleaning solutions designed for your specific ink type to avoid damaging your printer head.

Effectiveness of Cleaning Methods

The effectiveness of cleaning methods varies depending on the printer model, ink type, and severity of the ink clog.

- Inkjet printers: Manual cleaning techniques, such as using a cotton swab and isopropyl alcohol, are often effective for removing minor ink clogs in inkjet printers.

- Specialized cleaning solutions designed for inkjet printers can be more effective for stubborn clogs, particularly in models with multiple ink cartridges.

- However, some inkjet printers have delicate print heads that may require specialized cleaning procedures.

- Laser printers: Laser printers use toner, a dry powder, rather than ink.

- Dried toner can be removed using a specialized cleaning solution designed for laser printers.

- The cleaning process typically involves applying the solution to the toner cartridge or the printer’s internal components.

Printer Head Alignment

After cleaning the printer nozzles, it’s essential to align the printer head to ensure optimal print quality.

- Purpose of printer head alignment: A misaligned printer head can lead to blurry text, misaligned colors, and other print quality issues.

- Alignment ensures that the ink jets are properly positioned to deliver ink accurately onto the paper.

- Steps involved in the alignment process: The alignment process varies depending on the printer model.

- Access the alignment settings in the printer’s control panel or software.

- Print a test pattern, which will show any misalignment issues.

- Adjust the alignment settings based on the test pattern results.

- Tips for achieving optimal alignment:

- Ensure that the printer is on a level surface and that the paper is properly loaded.

- Follow the manufacturer’s s for alignment, as they are specific to each printer model.

- If you’re unable to achieve proper alignment, contact the printer manufacturer or a qualified technician for assistance.

| Cleaning Method | Ink Type | Printer Model | Effectiveness | Risks/Precautions |

|---|---|---|---|---|

| Cotton swab and isopropyl alcohol | Dye-based, Pigment-based | Inkjet | Moderate | Avoid excessive pressure, use caution around sensitive parts |

| Syringe and cleaning solution | Dye-based, Pigment-based | Inkjet | High | Follow manufacturer s, ensure thorough drying |

| Needle and thread | Dye-based, Pigment-based | Inkjet | High | Exercise extreme caution, avoid damaging the printer head |

| Specialized cleaning solution | Dye-based, Pigment-based, Sublimation, UV-curable | Inkjet, Laser | Varies | Check compatibility, follow manufacturer s |

Ink Maintenance for Extended Periods

When you’re not using your printer regularly, taking extra steps to preserve your ink cartridges and printer can save you money and frustration in the long run. Here’s how to ensure your printer remains ready for action when you need it.

Storing Ink Cartridges for Extended Periods

Storing ink cartridges correctly is crucial for preventing ink from drying out. Ink can clog the print head, causing poor print quality or even damage to the printer. Here are some key steps to follow:

- Remove the cartridges from the printer.This is the first step to prevent ink from drying out in the printer head.

- Clean the print head.Use a lint-free cloth and a solution specifically designed for cleaning printer heads. Avoid using water or other liquids that could damage the print head.

- Store cartridges in a cool, dry place.Extreme temperatures and humidity can accelerate ink drying. Avoid storing cartridges in direct sunlight or near heat sources.

- Use airtight containers.This will help to prevent the ink from evaporating. Some cartridges come with protective caps or seals; use these when storing the cartridges.

- Store cartridges upright.This helps to prevent ink from leaking out of the cartridge.

Using Printer Maintenance Kits

Printer maintenance kits are specifically designed to help keep your printer in top condition during extended periods of inactivity. These kits often contain:

- Cleaning solutions.These solutions help to remove dried ink and debris from the print head, preventing clogging.

- Protective caps.These caps are designed to seal the print head and prevent ink from drying out.

- Instructions.These instructions provide detailed guidance on how to use the kit and maintain your printer for extended periods.

Potential Risks of Leaving Ink Cartridges in the Printer, How do you keep printer ink from drying out

Leaving ink cartridges in the printer for extended periods without use can lead to several problems:

- Ink drying out.This can cause clogging of the print head, leading to poor print quality or even damage to the printer.

- Ink leaking.Over time, ink can leak from the cartridges and damage the printer’s internal components.

- Cartridge deterioration.Ink cartridges can deteriorate over time, even if they are not used. This can lead to problems with print quality or the inability to use the cartridges.

Ink Drying Prevention Strategies

Ink drying is a common problem that can affect both printers and cartridges. There are various strategies you can employ to minimize the chances of your ink drying out and ensure your printer continues to function smoothly.

Ink-Saving Features

Using your printer’s ink-saving features can significantly reduce ink consumption, thus minimizing the risk of ink drying. Many printers come equipped with features like draft mode, which prints at a lower resolution, and grayscale printing, which utilizes only black ink.

These features can help conserve ink without sacrificing print quality for everyday documents.

Frequently Asked Questions

How often should I clean my printer head?

It’s recommended to clean your printer head every 1-3 months, or more frequently if you notice any print quality issues. Regular cleaning helps prevent ink clogs and ensures optimal print performance.

What happens if I use the wrong type of ink in my printer?

Using incompatible ink can damage your printer’s print head and lead to poor print quality. Always use the ink type specifically recommended for your printer model.

Can I store ink cartridges in the refrigerator?

While storing ink cartridges in the refrigerator might seem like a good idea, it’s not recommended. The temperature fluctuations and humidity can actually accelerate ink drying.

Is it better to use dye-based or pigment-based ink?

The choice between dye-based and pigment-based ink depends on your printing needs. Dye-based inks are typically more vibrant but fade faster, while pigment-based inks are more archival but might have slightly less vibrant colors. Consider the type of printing you do and choose accordingly.

Can I use a hairdryer to dry ink faster?

Using a hairdryer to dry ink is not recommended. The heat from the hairdryer can damage the paper and cause the ink to bleed or smudge.