How do you print on glass? It’s a question that sparks curiosity, especially when considering the unique challenges and possibilities associated with this process. From intricate designs on architectural windows to personalized artwork on glass surfaces, printing on glass has become increasingly popular in various industries.

This guide will delve into the world of glass printing, exploring the techniques, materials, and applications that make it possible to transform glass into a canvas for creativity and functionality. Whether you’re a professional artist, a DIY enthusiast, or simply curious about this fascinating process, this comprehensive guide will provide valuable insights and practical knowledge.

Understanding the Process

Printing on glass is a fascinating process that combines artistic expression with advanced technology. It allows us to transform ordinary glass surfaces into captivating masterpieces, adding a touch of elegance and personalization to our surroundings.

Types of Glass Suitable for Printing

The type of glass you choose plays a crucial role in the success of your printing project. Different glass types have varying properties that affect the printing process and the final outcome.

- Float Glass:This is the most common type of glass used for printing. It’s flat, smooth, and transparent, making it ideal for a wide range of applications.

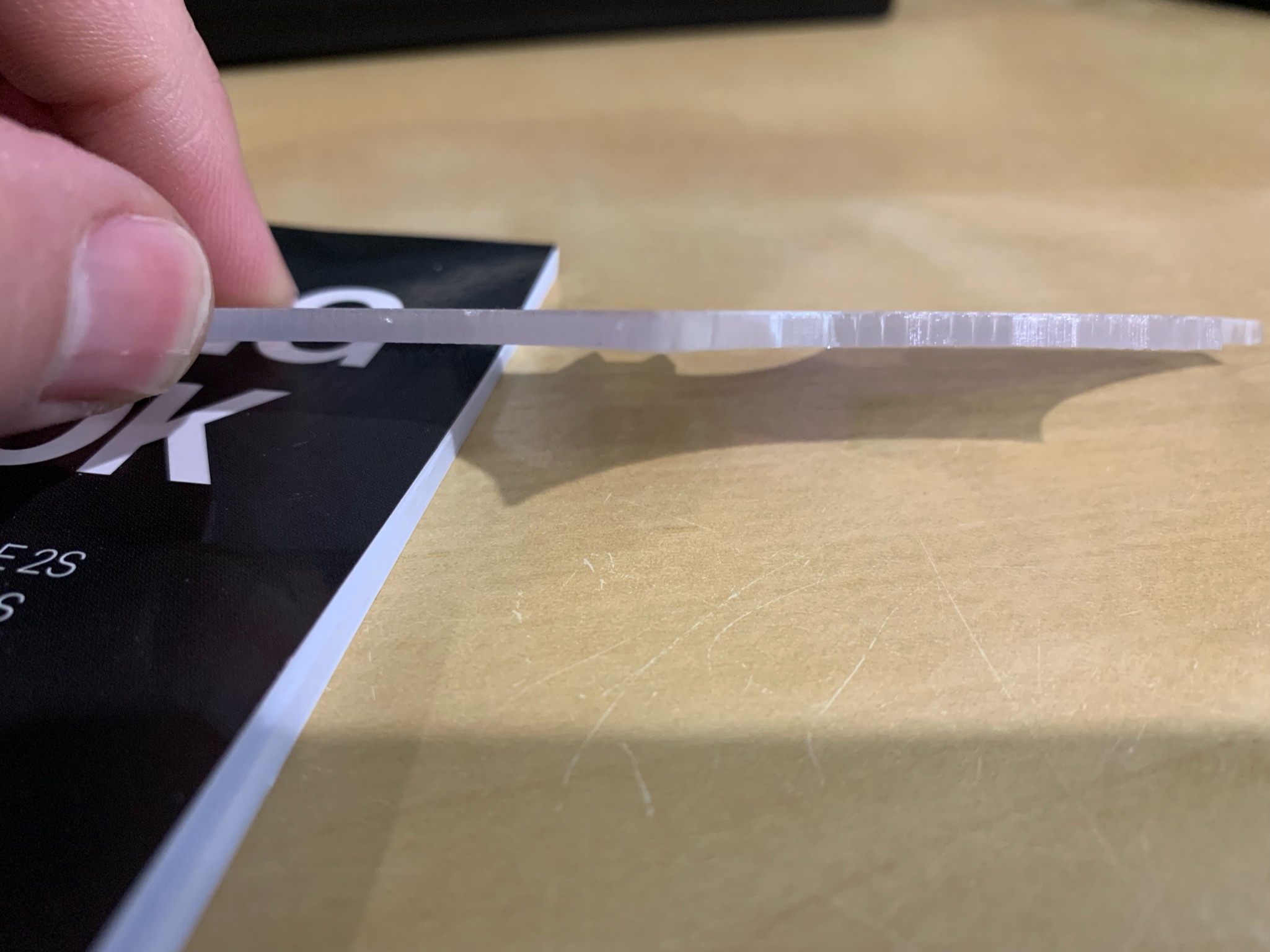

- Tempered Glass:Known for its durability and resistance to breakage, tempered glass is suitable for printing on surfaces requiring strength, such as shower doors or tabletops.

- Laminated Glass:This type of glass consists of two or more layers of glass bonded together with a plastic interlayer. It’s particularly well-suited for printing on surfaces that need to be shatterproof, such as windows and car windshields.

Advantages and Limitations of Printing on Glass

Printing on glass offers several advantages, but it also comes with some limitations.

- Advantages:

- Durability:Printed designs on glass are resistant to scratches, fading, and water damage, making them long-lasting.

- Versatility:Glass can be printed with a wide range of colors, designs, and finishes, allowing for creative expression.

- Uniqueness:Printing on glass creates unique and personalized pieces that stand out from the ordinary.

- Aesthetic Appeal:Glass surfaces add a touch of elegance and sophistication to any space.

- Limitations:

- Cost:Printing on glass can be more expensive than printing on other materials.

- Technical Expertise:The printing process requires specialized equipment and knowledge.

- Limited Design Options:Certain design elements may not translate well to glass printing.

Printing Methods: How Do You Print On Glass

Printing on glass involves transferring an image or design onto the glass surface using various techniques. The method used depends on the desired outcome, the complexity of the design, and the budget. Each method has its own advantages and disadvantages.

Printing on glass is a unique process that requires specialized equipment and materials. You’ll need a printer that can handle glass substrates and inks that are formulated for adhesion and durability. But before you get started, you might be wondering if you need a library card to print.

This article explains whether you need a library card to print at a library. Once you’ve got your setup sorted, you can create stunning custom designs on glass surfaces for everything from decorative pieces to functional items.

Direct Printing

Direct printing methods involve applying ink directly onto the glass surface. This method is commonly used for simple designs and small-scale production.

- Screen Printing:This method involves creating a stencil on a mesh screen. Ink is then forced through the stencil onto the glass surface. Screen printing is a versatile method that can be used to print a wide range of colors and designs.

It is commonly used for printing logos, graphics, and text onto glass products.

- Pad Printing:This method uses a flexible pad to transfer ink from a printing plate onto the glass surface. Pad printing is ideal for printing curved or irregular surfaces, and it is often used for printing small, intricate designs. It is commonly used for printing logos and graphics onto glass bottles, jars, and other products.

Digital Printing

Digital printing is a relatively new method that uses digital images to print onto glass. This method offers a high level of detail and precision, and it is ideal for creating custom designs.

- UV Printing:This method uses UV-curable inks that are cured with ultraviolet light. UV printing is a fast and efficient method that produces high-quality prints with vibrant colors. It is commonly used for printing photographs, artwork, and other complex designs onto glass.

Table of Printing Methods

The following table summarizes the different printing methods for glass, highlighting their advantages and disadvantages:

| Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Direct Printing | Applying ink directly onto the glass surface. | Simple and cost-effective. | Limited detail and precision. |

| Digital Printing | Using digital images to print onto glass. | High level of detail and precision. | More expensive than direct printing. |

| Screen Printing | Using a stencil on a mesh screen to apply ink. | Versatile, suitable for various colors and designs. | Requires specialized equipment. |

| Pad Printing | Using a flexible pad to transfer ink from a printing plate. | Ideal for printing curved or irregular surfaces. | Limited in terms of design complexity. |

| UV Printing | Using UV-curable inks that are cured with ultraviolet light. | Fast, efficient, and produces high-quality prints. | Requires specialized equipment. |

Preparing the Glass Surface

A clean and properly prepared glass surface is crucial for successful printing. It ensures that the ink adheres properly and creates a durable, long-lasting print. This involves removing any contaminants, creating a suitable surface for the ink to bond to, and protecting areas that shouldn’t be printed.

Cleaning and Degreasing the Glass Surface

Cleaning the glass surface is essential to remove any dirt, dust, grease, or fingerprints that could interfere with the printing process.

- Start by washing the glass with warm, soapy water. Use a soft cloth or sponge to gently scrub the surface, ensuring you reach all areas.

- Rinse the glass thoroughly with clean water to remove all soap residue.

- After rinsing, use a glass cleaner or rubbing alcohol to further degrease the surface. This removes any remaining oils or contaminants that soap might not have removed.

- Dry the glass surface completely with a lint-free cloth. This prevents streaks or watermarks that could affect the print quality.

Applying a Primer or Adhesion Promoter

A primer or adhesion promoter helps the ink adhere to the smooth glass surface. It creates a rougher texture that allows the ink to grip better, preventing peeling or flaking.

- Choose a primer specifically designed for glass surfaces. There are different types available, including acrylic, epoxy, and polyurethane-based primers.

- Apply the primer evenly to the glass surface using a brush, roller, or spray gun. Follow the manufacturer’s instructions for drying time and application thickness.

- Allow the primer to dry completely before proceeding to the next step. This ensures proper adhesion and prevents the ink from bleeding into the primer.

Masking Off Areas Not Intended for Printing

Masking is crucial for protecting areas of the glass that you don’t want to be printed. This ensures clean lines and prevents ink from spreading to unwanted areas.

- Use masking tape designed for glass surfaces. It should adhere well to the glass and be easy to remove without leaving residue.

- Apply the masking tape carefully, ensuring it is smooth and free of wrinkles or air bubbles. This prevents ink from seeping underneath the tape.

- Use a sharp utility knife to cut precise shapes or designs within the masked areas, creating detailed patterns or protecting specific sections of the glass.

Choosing the Right Inks and Coatings

The choice of inks and coatings is crucial for achieving the desired aesthetic and functional qualities of your printed glass project. Factors like durability, colorfastness, transparency, and the type of glass surface will influence your decision.

Ink Types and Their Properties

Different ink types offer unique advantages and disadvantages. Understanding these differences will help you choose the best option for your project.

- Solvent-based inksare known for their vibrant colors, excellent adhesion, and durability. They dry quickly and are resistant to scratching and fading. However, they can emit volatile organic compounds (VOCs) during the printing process, requiring proper ventilation. They are also not suitable for all glass surfaces, particularly those that are porous or have a rough texture.

- Water-based inksare a more environmentally friendly alternative to solvent-based inks. They are less likely to emit VOCs and are easier to clean up. They offer good adhesion and colorfastness but may not be as durable or scratch-resistant as solvent-based inks. They are suitable for a wider range of glass surfaces, including those that are porous.

- UV-curable inksare a popular choice for glass printing due to their rapid curing time, high adhesion, and excellent scratch resistance. They are also known for their vibrant colors and good colorfastness. UV-curable inks require a UV lamp for curing, which adds to the equipment cost.

- Ceramic inksare highly durable and scratch-resistant, offering excellent colorfastness and UV resistance. They are often used for decorative glass applications, like tiles or tableware, as they can withstand high temperatures. Ceramic inks require a high-temperature firing process, which adds to the cost and complexity of the printing process.

Post-Printing Processes

After you’ve printed your design onto the glass, it’s time to take steps to ensure its longevity and enhance its visual appeal. This involves a series of post-printing processes that protect the ink, enhance its vibrancy, and make your creation resistant to wear and tear.

Curing or Drying the Printed Surface

The first step after printing is to cure or dry the printed surface. This process allows the ink to solidify and bond with the glass, preventing it from smudging or fading. The curing method depends on the type of ink used.

- UV Curable Inks:These inks are cured using ultraviolet (UV) light. The UV light triggers a chemical reaction in the ink, causing it to harden quickly. UV curing is often used for high-volume production as it is fast and efficient.

- Solvent-Based Inks:These inks require a drying period, typically at room temperature or in a controlled environment. The drying time depends on the thickness of the ink layer and the environmental conditions.

- Water-Based Inks:Similar to solvent-based inks, water-based inks need to dry thoroughly. They are generally cured at room temperature and may require a longer drying time than solvent-based inks.

Applying a Protective Coating or Sealant

Once the ink is cured, a protective coating or sealant can be applied to further enhance the durability and aesthetics of the printed glass. These coatings provide a barrier against scratches, abrasion, and UV damage.

- Clear Coatings:These coatings are transparent and invisible, protecting the printed design without altering its appearance. They are commonly used for enhancing scratch resistance and UV protection.

- Gloss Coatings:These coatings add a shiny, reflective finish to the printed glass, enhancing its visual appeal and providing a protective layer. They are often used for decorative purposes.

- Matte Coatings:These coatings provide a non-reflective, velvety finish to the printed glass, reducing glare and enhancing the depth of the design. They are often used for creating a subtle, sophisticated look.

Firing or Annealing the Printed Glass, How do you print on glass

For certain types of glass printing, particularly those involving ceramic inks, a firing or annealing process is necessary. This involves heating the glass to a high temperature, allowing the ink to fuse with the glass surface. This process creates a permanent bond between the ink and the glass, making the printed design extremely durable and resistant to scratching, fading, and chipping.

Firing temperatures and durations vary depending on the type of glass and the specific ink used.

Applications of Printed Glass

Printed glass has revolutionized various industries, offering a versatile medium for creativity and functionality. From architectural marvels to everyday objects, printed glass has become an integral part of our modern world.

Applications of Printed Glass Across Industries

The versatility of printed glass makes it suitable for a wide range of applications across various industries. Here’s a table showcasing some prominent examples:

| Industry | Applications | Examples |

|---|---|---|

| Architecture | Façade designs, windows, partitions, decorative elements, sunshades | Printed glass panels with intricate patterns for building exteriors, glass walls with custom designs for interior spaces, frosted glass partitions for privacy, and sunshades with UV-resistant prints to reduce heat gain |

| Interior Design | Furniture, decorative accents, kitchen backsplashes, shower enclosures, tabletops, mirrors | Printed glass tabletops with artistic designs, kitchen backsplashes with vibrant patterns, shower enclosures with frosted glass for privacy, and mirrors with custom artwork |

| Automotive | Windshields, sunroofs, side windows, taillights, interior panels | Windshields with embedded sensors for advanced driver-assistance systems, sunroofs with tinted glass for heat control, side windows with custom designs, taillights with LED integration, and interior panels with decorative prints |

| Electronics | Touchscreens, displays, protective coatings, circuit boards | Smartphones with printed glass touchscreens, high-definition displays with anti-reflective coatings, protective glass for electronic devices, and circuit boards with printed conductive patterns |

| Art and Craft | Artwork, sculptures, decorative objects, stained glass | Printed glass panels with abstract designs, glass sculptures with intricate patterns, decorative objects with custom prints, and stained glass windows with vibrant colors |

Creative and Functional Uses of Printed Glass

Printed glass offers a wide array of creative and functional uses, enriching our lives in numerous ways.

- Architectural Façades:Printed glass panels can transform building exteriors, creating stunning visual effects and enhancing energy efficiency. Architects use printed glass to incorporate intricate patterns, vibrant colors, and custom designs, adding a unique touch to building façades.

- Interior Design:Printed glass finds its way into interior spaces, creating captivating decorative accents. From kitchen backsplashes to shower enclosures, printed glass adds a touch of elegance and functionality. Printed glass tabletops, for instance, can showcase artistic designs or personalized messages, making them conversation starters.

- Automotive Applications:Printed glass plays a crucial role in the automotive industry, enhancing both functionality and aesthetics. Windshields with embedded sensors enable advanced driver-assistance systems, while sunroofs with tinted glass provide heat control and a panoramic view. Printed glass is also used for decorative interior panels, adding a touch of personalization to vehicles.

- Electronics:Printed glass is essential for electronic devices, enabling touchscreens, displays, and protective coatings. Printed conductive patterns on circuit boards enhance the functionality of electronic devices, while anti-reflective coatings on displays improve visibility and reduce glare.

- Art and Craft:Printed glass has become a popular medium for artists and crafters, offering endless creative possibilities. Printed glass panels can be used to create stunning artwork, sculptures with intricate patterns, and decorative objects with personalized designs. Stained glass windows with vibrant colors add a touch of beauty and artistry to homes and public spaces.

Safety Considerations

Printing on glass can be a rewarding and creative process, but it’s essential to prioritize safety throughout the project. Working with glass, inks, and equipment requires awareness and adherence to safety guidelines to prevent accidents and injuries.

Handling Hazardous Materials

It’s crucial to understand the potential hazards associated with the materials used in glass printing.

- Inks:Many printing inks contain solvents, pigments, and other chemicals that can be flammable, toxic, or irritating. Always wear appropriate personal protective equipment (PPE), such as gloves, masks, and eye protection, when handling inks. Follow the manufacturer’s safety data sheets (SDS) for specific instructions on handling, storage, and disposal.

- Coatings:Coatings used to protect the printed image or enhance its durability may also contain hazardous materials. Similar to inks, read the SDS carefully and wear appropriate PPE.

- Cleaners:Cleaning solutions used to prepare the glass surface or remove excess ink can be corrosive or toxic. Ensure proper ventilation and wear gloves and eye protection when using these products.

Working with High Temperatures

Some printing methods, such as screen printing and digital printing with UV curing, involve high temperatures.

- UV Curing:UV lamps emit high-intensity ultraviolet (UV) light that can cause eye damage. Always wear UV-protective eyewear when operating UV curing equipment.

- Kiln Firing:Kiln firing, a process used for ceramic-based inks, involves high temperatures that can cause burns. Wear heat-resistant gloves and protective clothing when handling hot glass or working near the kiln.

Using Sharp Tools or Equipment

Glass printing may involve using sharp tools or equipment, which can cause cuts or other injuries.

- Knives and Scissors:When cutting stencils, masks, or other materials, use sharp tools with caution. Keep fingers away from the blade and use a cutting mat to protect your work surface.

- Squeegees:Squeegees are used to apply ink to the glass surface. Use them with firm pressure but avoid excessive force, as this can cause the glass to break.

- Glass Handling:Always handle glass with care, as it can easily break. Use gloves and wear safety glasses to protect your hands and eyes from shards.

Future Trends in Glass Printing

The world of glass printing is constantly evolving, with exciting advancements on the horizon. Emerging technologies and innovations are poised to revolutionize the way we design, manufacture, and interact with glass products.

3D Printing on Glass

D printing on glass is a rapidly developing field that holds immense potential for creating intricate and functional designs. This technique involves building up layers of glass powder or liquid glass using a focused laser or electron beam. The process allows for the creation of complex geometries, customized patterns, and even embedded functionalities like sensors and electronics.

“3D printing on glass offers a paradigm shift in glass fabrication, enabling the creation of complex and customized designs with unprecedented freedom.”

Digital Printing with Higher Resolution and Color Accuracy

Digital printing on glass has made significant strides in recent years, with advancements in resolution and color accuracy. The use of high-resolution inkjet printers allows for the creation of intricate patterns, realistic images, and vibrant colors on glass surfaces. This technology is particularly beneficial for applications requiring detailed designs, such as architectural glass, decorative glass, and artistic glass creations.

“The increasing resolution and color accuracy of digital printing on glass enables the creation of stunning and highly detailed designs, pushing the boundaries of artistic expression and design possibilities.”

Development of New Inks and Coatings with Enhanced Properties

Research and development efforts are focused on creating new inks and coatings with enhanced properties for glass printing. These innovations aim to address specific challenges such as durability, scratch resistance, UV protection, and water repellency.

“The development of advanced inks and coatings with enhanced properties will enable the creation of glass products with improved functionality and aesthetics, opening up new avenues for innovation and design.”

FAQ Overview

What are the most common types of glass used for printing?

Common types include float glass, tempered glass, and laminated glass. The choice depends on the application and desired durability.

Is printing on glass expensive?

The cost varies depending on the printing method, size, complexity of the design, and quantity. Some methods like screen printing can be more cost-effective for larger quantities.

Can I print on glass at home?

Yes, you can try DIY glass printing with specialized kits or using techniques like screen printing. However, professional results often require specialized equipment and expertise.