How does an inkless printer work? It’s a question that sparks curiosity, especially considering the traditional image of ink cartridges and messy spills. Inkless printing, however, offers a refreshing approach, relying on innovative technologies that eliminate the need for liquid ink altogether.

From thermal to electrostatic methods, these printers utilize heat, electricity, or dye sublimation to create images, offering a range of advantages and unique applications.

This article delves into the fascinating world of inkless printing, exploring its various types, working principles, and potential applications. We’ll unravel the mysteries behind these cutting-edge technologies, highlighting their advantages and limitations, and providing insights into the future of inkless printing.

Introduction to Inkless Printing

Inkless printing is a revolutionary technology that eliminates the need for traditional ink cartridges, offering a sustainable and cost-effective alternative. It uses various methods to create images and text on paper without relying on liquid ink.Inkless printing offers numerous advantages over conventional ink-based printing, including:

Advantages of Inkless Printing

Inkless printing boasts several advantages that make it an appealing option for individuals and businesses alike.

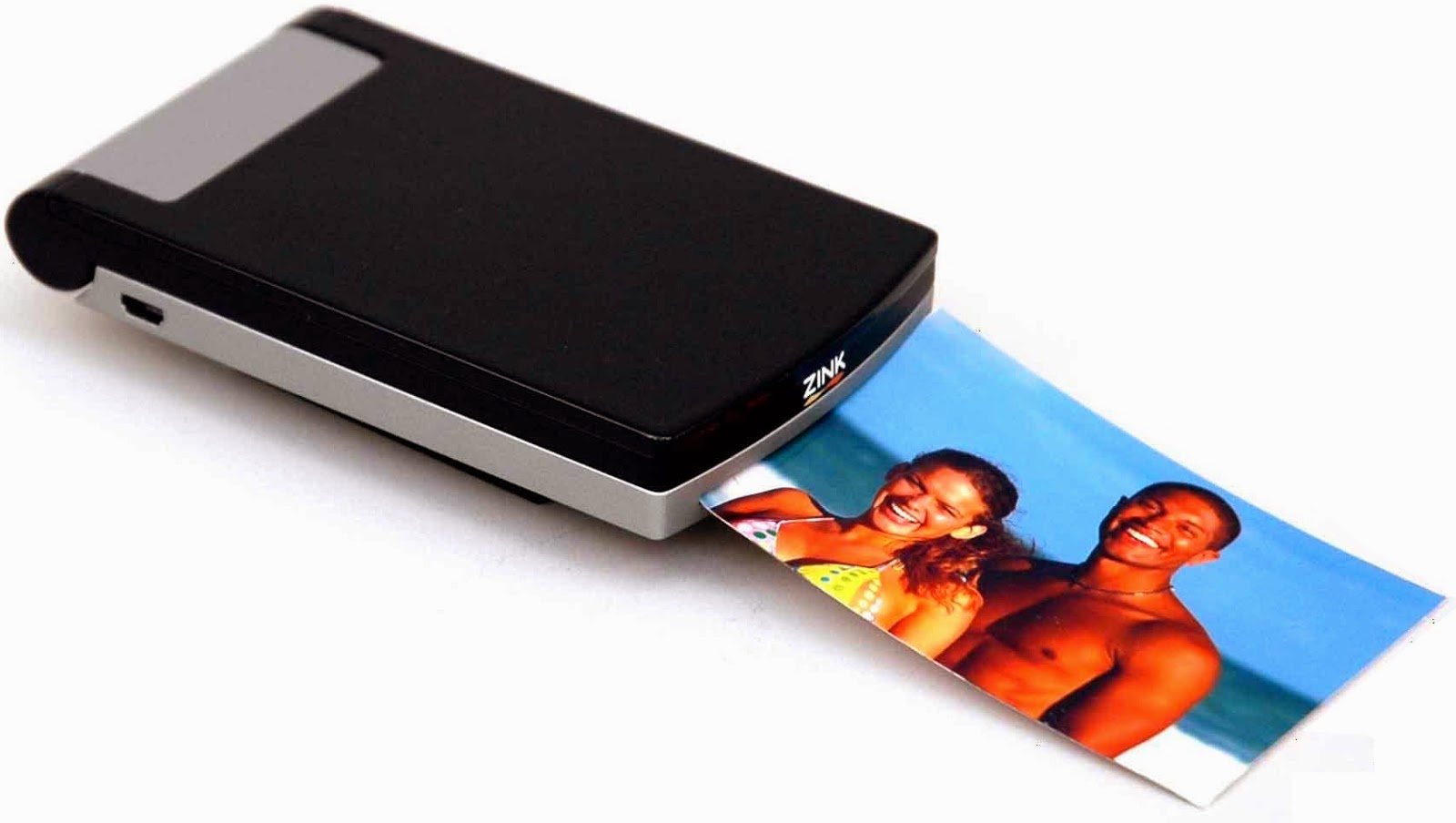

Inkless printers are a cool way to print without having to worry about ink cartridges. They use a special kind of paper that’s coated with a heat-sensitive dye. When the printer heats up the paper, the dye reacts and creates the image.

But you might be wondering, does printer ink expire ? Well, since inkless printers don’t use traditional ink, the question of expiration doesn’t really apply. They rely on the special paper and heat technology, so you don’t have to worry about your printer running out of ink.

- Cost-Effectiveness:Inkless printers eliminate the recurring expense of ink cartridges, leading to significant cost savings over time.

- Environmental Sustainability:Inkless printing reduces waste associated with ink cartridges, contributing to a greener printing solution.

- Reduced Maintenance:Inkless printers generally require less maintenance than their ink-based counterparts, simplifying their operation.

- High Print Quality:Modern inkless printing technologies produce high-quality prints comparable to traditional ink-based methods.

History of Inkless Printing Technology

Inkless printing technology has evolved over time, with several notable milestones shaping its development.

- Early Innovations:The concept of inkless printing dates back to the 19th century, with early experiments involving thermal printing and wax-based printing methods.

- Thermal Printing:In the mid-20th century, thermal printing emerged as a viable inkless printing method, utilizing heat to transfer images onto heat-sensitive paper.

- Dye Sublimation:Dye sublimation printing, introduced in the 1980s, uses heat to transfer dye onto paper, creating high-quality, vibrant prints.

- Electrostatic Printing:Electrostatic printing utilizes electric charges to transfer toner particles onto paper, creating images without liquid ink.

Types of Inkless Printers

Inkless printers offer a compelling alternative to traditional inkjet and laser printers, providing unique advantages and functionalities. These printers employ diverse technologies to produce high-quality prints without relying on ink cartridges.

Thermal Printers

Thermal printers are a common type of inkless printer that utilizes heat to create images on specially coated paper. These printers work by applying heat to a thermal head, which then transfers the heat to the paper. The paper contains a heat-sensitive coating that changes color when exposed to heat.

This process creates the image or text on the paper.Thermal printers are widely used for printing receipts, labels, and other applications where high-volume printing is required.

- Advantages:

- Cost-effective: Thermal printers are generally cheaper than other types of inkless printers.

- Simple operation: They are easy to use and maintain, with no ink cartridges to replace.

- Compact size: Thermal printers are typically compact and portable, making them suitable for various applications.

- Disadvantages:

- Limited print quality: Thermal prints can fade over time, especially when exposed to sunlight or heat.

- Specialized paper: Thermal printers require specific heat-sensitive paper, which may be more expensive than regular paper.

- Limited color options: Most thermal printers only print in black and white.

Dye-Sublimation Printers

Dye-sublimation printers utilize a heat-transfer process to create high-quality prints with vibrant colors and smooth gradients. These printers use a ribbon coated with solid dye inks. When heat is applied to the ribbon, the dye inks vaporize and transfer to the printing medium, typically a specialized paper or fabric.Dye-sublimation printers are commonly used for printing photographs, artwork, and other applications where high-quality color reproduction is essential.

- Advantages:

- Excellent print quality: Dye-sublimation prints offer vibrant colors, smooth gradients, and high resolution.

- Durable prints: The prints are water-resistant and fade-resistant, making them suitable for long-term use.

- Wide color gamut: Dye-sublimation printers can reproduce a wide range of colors, including subtle shades and gradients.

- Disadvantages:

- Higher cost: Dye-sublimation printers are typically more expensive than other types of inkless printers.

- Specialized media: They require specific dye-sublimation paper or fabric, which can be more expensive than regular paper.

- Slow printing speed: Dye-sublimation printing can be slower than other printing methods.

Electro-Inkjet Printers

Electro-inkjet printers use a technology called electro-inkjet, which employs an electric field to eject ink droplets onto the printing medium.Electro-inkjet printers utilize a specialized ink cartridge containing an ink solution with conductive properties. When an electric field is applied to the ink, it creates a force that pushes ink droplets onto the paper.Electro-inkjet printers are becoming increasingly popular for their ability to produce high-quality prints at a relatively low cost.

- Advantages:

- High-quality prints: Electro-inkjet printers can produce high-resolution prints with sharp details and accurate colors.

- Low running costs: Electro-inkjet printers use less ink than traditional inkjet printers, resulting in lower running costs.

- Fast printing speed: Electro-inkjet printers can print at a relatively fast speed.

- Disadvantages:

- Limited color gamut: Electro-inkjet printers may have a more limited color gamut compared to dye-sublimation printers.

- Ink drying: The ink used in electro-inkjet printers can dry out quickly if the printer is not used regularly.

- Potential for clogging: Electro-inkjet printers can be prone to clogging if the ink nozzles are not cleaned regularly.

Thermal Inkless Printing

Thermal inkless printing, also known as direct thermal printing, is a printing method that utilizes heat to create images on special heat-sensitive paper. This method is commonly used in receipt printers, label printers, and some portable printers.

How Thermal Inkless Printing Works, How does an inkless printer work

Thermal inkless printing uses a thermal print head that contains a series of tiny resistors. When an electrical signal is sent to a resistor, it heats up. This heat is then transferred to the heat-sensitive paper, causing a chemical reaction that creates a dark mark.

The intensity of the mark is controlled by the amount of heat applied.

Advantages and Disadvantages of Thermal Inkless Printing

Thermal inkless printing offers several advantages, including:

- Simplicity:Thermal inkless printers are simple to operate and maintain, as they do not require ink cartridges or other consumables.

- Cost-effectiveness:This printing method is relatively inexpensive, as it only requires heat-sensitive paper.

- Reliability:Thermal inkless printers are known for their reliability and durability.

- Compactness:Thermal inkless printers are typically compact and lightweight, making them suitable for portable applications.

However, thermal inkless printing also has some limitations:

- Image Quality:The image quality of thermal inkless printing is generally lower than that of inkjet or laser printing. Images may appear grainy or faded, and the print quality can be affected by environmental factors such as humidity and temperature.

- Limited Color Options:Thermal inkless printing is typically limited to black and white printing. While some printers offer limited color capabilities, the quality and range of colors are often inferior to other printing methods.

- Fading:Images printed using thermal inkless printing can fade over time, especially if exposed to sunlight or high temperatures.

- Paper Type:Thermal inkless printers require specialized heat-sensitive paper, which can be more expensive and less readily available than standard paper.

Electrostatic Inkless Printing: How Does An Inkless Printer Work

Electrostatic inkless printing is a technology that uses electric charges to transfer images onto a surface. It’s a unique approach that doesn’t rely on traditional inks or toners, making it a compelling option for certain applications.

How Electrostatic Inkless Printing Works

The core of electrostatic inkless printing is the manipulation of electric charges. The process begins with an image being converted into an electrical signal. This signal then controls the application of electric charges to a special material, typically a thin film or a drum.

The charged areas on the material attract particles of a dry, powdered ink, known as toner. The toner particles adhere to the charged areas, forming the image. The image is then transferred to the final substrate, such as paper or a fabric.

Role of Electric Charges in Image Transfer

Electric charges play a crucial role in electrostatic inkless printing. The charges create an electrostatic field, which attracts and holds the toner particles. This process is similar to how magnets attract and hold metal objects. The distribution of charges on the material directly corresponds to the image being printed.

For example, areas of the material with a higher concentration of positive charges will attract more toner particles, resulting in a darker image.

Applications of Electrostatic Inkless Printing

Electrostatic inkless printing finds its niche in various applications:

- Direct-to-garment printing:This method allows for high-quality, vibrant prints directly on fabric. It’s particularly popular for personalized clothing, sportswear, and promotional apparel.

- Industrial labeling:Electrostatic printing excels in creating durable labels for various industrial applications, including packaging, shipping, and product identification.

- Security printing:Due to its ability to create intricate patterns and fine details, electrostatic printing is used in security printing for documents like banknotes, passports, and certificates.

Dye Sublimation Inkless Printing

Dye sublimation printing is a unique inkless printing technology that uses heat to transfer solid dyes onto paper. It’s a fascinating process that produces high-quality images with vibrant colors and exceptional durability.

Dye Sublimation Process

Dye sublimation printing involves transferring solid dyes onto a special coated paper using heat and pressure. This process results in high-quality images with smooth transitions and exceptional color accuracy. The process involves the following steps:

- Solid Dye Ribbon:The printer uses a ribbon containing solid dyes in different colors. Each color has a specific layer on the ribbon.

- Heat and Pressure:The print head heats the dye ribbon, causing the dyes to transition directly from a solid state to a gaseous state, bypassing the liquid phase. This process is known as sublimation.

- Dye Transfer:The gaseous dyes are then transferred onto the special coated paper, which has a heat-sensitive coating. The paper absorbs the dyes, resulting in a permanent image.

- Image Formation:As the dyes cool down, they solidify on the paper, creating a vibrant and long-lasting image.

Advantages of Dye Sublimation Printing

Dye sublimation printing offers several advantages over traditional ink-based printing methods. Some of the key advantages include:

- High Image Quality:Dye sublimation produces images with exceptional color accuracy, smooth gradients, and high resolution. This makes it ideal for applications that require high-quality prints, such as professional photography and graphic design.

- Long-lasting Images:The images produced using dye sublimation are highly durable and resistant to fading, water, and scratches. This is because the dyes are permanently embedded within the paper fibers.

- Wide Color Gamut:Dye sublimation printers can produce a wider range of colors than traditional ink-based printers. This is because they use a wider color palette and can achieve smoother color transitions.

Inkless Printing Technology Applications

Inkless printing technology has emerged as a revolutionary approach to printing, offering numerous advantages over traditional ink-based methods. It finds applications in diverse industries and sectors, catering to a wide range of printing needs.

Inkless Printing Applications Across Industries

Inkless printing technology offers a diverse range of applications across various industries. The following table Artikels some of the key applications by industry, technology type, and advantages:| Industry | Technology Type | Advantages ||—|—|—|| Retail| Thermal Inkless Printing | High-speed printing, low running costs, energy efficiency, compact size|| Healthcare| Electrostatic Inkless Printing | High-resolution printing, durable prints, suitable for medical records and labels, compatibility with various materials|| Manufacturing| Dye Sublimation Inkless Printing | Vibrant and high-quality prints, waterproof and fade-resistant, suitable for product labeling, packaging, and promotional materials|| Education| Thermal Inkless Printing | Cost-effective printing, low maintenance, easy to use, ideal for student assignments and educational materials|| Government| Electrostatic Inkless Printing | High security printing, tamper-proof documents, suitable for official documents, ID cards, and security labels|| Event Management| Dye Sublimation Inkless Printing | Personalized printing, high-quality images and graphics, suitable for event badges, signage, and promotional materials|

Future of Inkless Printing

Inkless printing technology is still evolving, and its future holds promising possibilities for innovation and widespread adoption. With ongoing research and development, we can expect to see significant advancements in the coming years, leading to even more efficient, cost-effective, and environmentally friendly printing solutions.

Advancements in Inkless Printing Technology

The future of inkless printing is bright, with several potential advancements on the horizon. Here are some key areas where we can expect to see progress:

- Improved Print Quality:Researchers are working to enhance the resolution and color accuracy of inkless printing, aiming to achieve print quality comparable to traditional inkjet and laser printers. This will involve optimizing the printing mechanisms and developing new materials that can reproduce a wider range of colors and details.

- Faster Printing Speeds:Inkless printing technologies are constantly being refined to increase printing speeds. This will involve optimizing the printing process, using more efficient materials, and developing new printing mechanisms that can print faster without compromising print quality.

- Reduced Costs:As inkless printing technologies mature, we can expect to see a reduction in the cost of printing. This will be driven by factors such as economies of scale, improved manufacturing processes, and the development of more affordable materials.

- Increased Durability:One of the key advantages of inkless printing is the durability of the printed output. Continued research will focus on developing inks and printing processes that produce prints that are resistant to fading, smudging, and water damage. This will make inkless printing ideal for applications where print longevity is critical, such as archival documents, photographs, and artwork.

- Sustainability:Inkless printing offers a more environmentally friendly alternative to traditional printing methods. As the technology advances, we can expect to see further reductions in the environmental impact of printing, with a focus on using sustainable materials, reducing energy consumption, and minimizing waste.

Future Applications of Inkless Printing

The versatility of inkless printing technology opens up a wide range of potential applications beyond traditional document printing. Here are some exciting possibilities:

- Personalized Printing:Inkless printing could revolutionize personalized printing, allowing individuals to create unique and customized products, such as clothing, home decor, and gifts. Imagine being able to print a personalized design on a t-shirt or create a custom photo album with high-quality prints.

- 3D Printing:Inkless printing could play a significant role in the advancement of 3D printing technology. By using different materials and printing processes, inkless printing could enable the creation of complex 3D objects with intricate details and a wide range of textures and colors.

- Medical Imaging:Inkless printing could be used to create high-resolution medical images, allowing doctors to diagnose and treat patients more effectively. The ability to print images on various materials could also enable the creation of personalized medical devices and prosthetics.

- Security Printing:Inkless printing could be used to create tamper-proof security documents, such as banknotes, passports, and driver’s licenses. The unique properties of inkless printing make it difficult to counterfeit, enhancing security and protecting against fraud.

Impact on the Printing Industry

The rise of inkless printing is expected to have a significant impact on the printing industry, transforming how we print and consume printed materials. Here are some key impacts:

- Shift in Printing Technologies:The adoption of inkless printing will likely lead to a shift away from traditional inkjet and laser printing technologies. As inkless printing becomes more affordable and accessible, it could become the dominant printing technology in various applications.

- New Business Opportunities:The development of inkless printing technologies will create new business opportunities for companies involved in the manufacturing, distribution, and implementation of inkless printing solutions. It will also create new markets for personalized printing services and 3D printing applications.

- Increased Efficiency and Sustainability:The transition to inkless printing will drive increased efficiency and sustainability in the printing industry. The reduced reliance on ink cartridges and the use of sustainable materials will contribute to a greener printing ecosystem.

FAQ

What are the main types of inkless printers?

The primary types of inkless printers include thermal printers, electrostatic printers, and dye sublimation printers. Each utilizes a different mechanism for transferring images onto paper.

Are inkless printers more expensive than traditional printers?

The cost of inkless printers can vary depending on the type and features. Some inkless printers can be more expensive upfront, but they often offer long-term cost savings due to the absence of ink cartridges.

What are the advantages of using an inkless printer?

Advantages of inkless printing include reduced running costs, eco-friendliness (less waste), high-quality images, and the ability to print on various surfaces.

Are inkless printers suitable for everyday printing needs?

Inkless printers can be suitable for various printing needs, depending on the specific technology and application. They are commonly used for receipts, labels, photographs, and specialized printing tasks.