How much does screen printing cost? This question is often on the minds of businesses and individuals looking to create custom apparel, promotional products, or unique designs. Screen printing is a versatile and popular method for transferring images and designs onto various surfaces, but the cost can vary depending on a multitude of factors.

From the complexity of your design to the type of garment and the size of your order, numerous variables influence the final price tag. Understanding these factors and how they interact is crucial for making informed decisions and achieving the best value for your screen printing project.

Factors Influencing Screen Printing Costs

Screen printing costs can vary significantly based on several factors. Understanding these factors will help you make informed decisions and get the best value for your money.

Design Complexity

The complexity of your design directly impacts the cost of screen printing. A simple design with minimal detail will require less time and effort to create the screens, leading to a lower cost. However, intricate designs with fine lines, gradients, or multiple colors increase the complexity, resulting in higher costs.

Screen printing costs can vary depending on factors like the size of the design, the number of colors, and the quantity of shirts you need. Before you start printing, you’ll want to make sure your design is ready to go.

If you’re using a Canon printer, you might need to connect it to your laptop first – check out this guide on how can I connect my Canon printer to my laptop. Once your printer is set up, you can start printing out your designs and get ready to start screen printing!

Order Size

The quantity of items you order is another major factor. Screen printing is a process that involves setup costs for each design. These setup costs are spread across the total number of items printed. Therefore, larger orders have a lower cost per unit due to the fixed setup costs being divided among more items.

Conversely, smaller orders have a higher cost per unit.

Ink Type

The type of ink used can also affect the cost. Specialty inks, such as glow-in-the-dark, metallic, or discharge inks, are generally more expensive than standard plastisol inks. This is because they often require specific printing techniques or have unique properties that add to the production cost.

Garment Material

The material of the garment you’re printing on can also impact the price. Certain fabrics, like 100% cotton, are easier to print on and require less pre-treatment than blends or synthetics. Some materials may require specific inks or printing methods, leading to higher costs.

Number of Colors

The number of colors in your design is directly proportional to the cost. Each color requires a separate screen, which increases the setup time and effort. Therefore, a design with multiple colors will be more expensive than a design with fewer colors.

For example, a one-color design might cost $2 per unit, while a four-color design might cost $5 per unit.

Printing Location

The location of the screen printing shop can also influence the cost. Printing shops in major cities with higher operating costs may charge more than those in smaller towns or rural areas.

Printer Experience, How much does screen printing cost

The experience level of the screen printer can also play a role in the cost. Experienced printers with specialized skills and equipment may charge more for their services, but they often offer higher quality and consistency.

Screen Printing Cost Breakdown: How Much Does Screen Printing Cost

Understanding the individual components of screen printing costs helps you make informed decisions about your project and budget. This breakdown provides insights into the various expenses involved in bringing your screen printing design to life.

Design and Separation

The initial stage involves transforming your creative vision into a print-ready design. This process includes design creation, color separation, and film output.

- Design Creation:This step involves working with a graphic designer to develop your screen printing design. The cost depends on the complexity of the design, the designer’s experience, and the number of revisions required. For simple designs, expect to pay around $50-$100, while intricate designs can cost upwards of $200 or more.

- Color Separation:This process involves separating your design into individual color layers for each screen used in the printing process. This is crucial for achieving accurate color reproduction. The cost typically ranges from $10 to $30 per color, depending on the complexity of the design.

- Film Output:Once the color separation is complete, films are created for each color, acting as a blueprint for screen creation. The cost for film output typically ranges from $5 to $15 per color.

Screen Creation

Screens are the essential tools for transferring ink onto your garments. Each color in your design requires a separate screen.

- Screen Material:The cost of screen material depends on the mesh count and size of the screen. Higher mesh counts are used for finer details, while larger screens accommodate larger designs. The cost for screen material typically ranges from $10 to $30 per screen.

- Screen Preparation:This involves coating the screen with emulsion, a light-sensitive substance that creates the printing stencil. The cost for screen preparation can vary depending on the size and complexity of the design, typically ranging from $10 to $25 per screen.

- Screen Exposure:This step involves exposing the coated screen to a UV light source, hardening the emulsion where the design is present. The cost for screen exposure is usually included in the screen preparation cost.

- Screen Washing:After exposure, the screen is washed to remove unexposed emulsion, leaving behind the stencil for printing. The cost for screen washing is typically included in the screen preparation cost.

Printing Process

The printing process itself involves several steps, each contributing to the overall cost.

- Ink Cost:The cost of ink depends on the type, quantity, and color of ink used. Plastisol ink is a popular choice for screen printing, with prices varying based on the manufacturer and color. Expect to pay around $20-$50 per gallon of plastisol ink.

- Labor Cost:The cost of labor depends on the number of garments printed, the complexity of the design, and the printer’s experience. A skilled screen printer can typically print 100-200 garments per hour. The labor cost is usually calculated based on an hourly rate.

- Equipment Usage:Screen printing equipment includes a press, squeegee, and other tools. The cost of equipment usage is often factored into the printing cost, either as a flat fee or a per-garment charge.

Finishing and Packaging

Once the garments are printed, they may require additional finishing and packaging to ensure quality and presentation.

- Curing:Curing is the process of heat-setting the ink to ensure durability and prevent cracking. The cost for curing is usually included in the printing cost.

- Tagging:Adding tags to the garments is an essential part of the finishing process. The cost of tags depends on the type, quantity, and design. Expect to pay around $0.10-$0.50 per tag.

- Packaging:Packaging the printed garments is important for presentation and shipping. The cost of packaging depends on the type of packaging used, such as poly bags, boxes, or custom packaging.

Typical Screen Printing Costs

Screen printing costs can vary significantly depending on several factors, including order size, garment type, color count, and the type of printing service you choose. This section provides a general overview of typical screen printing costs for different scenarios.

Typical Screen Printing Costs

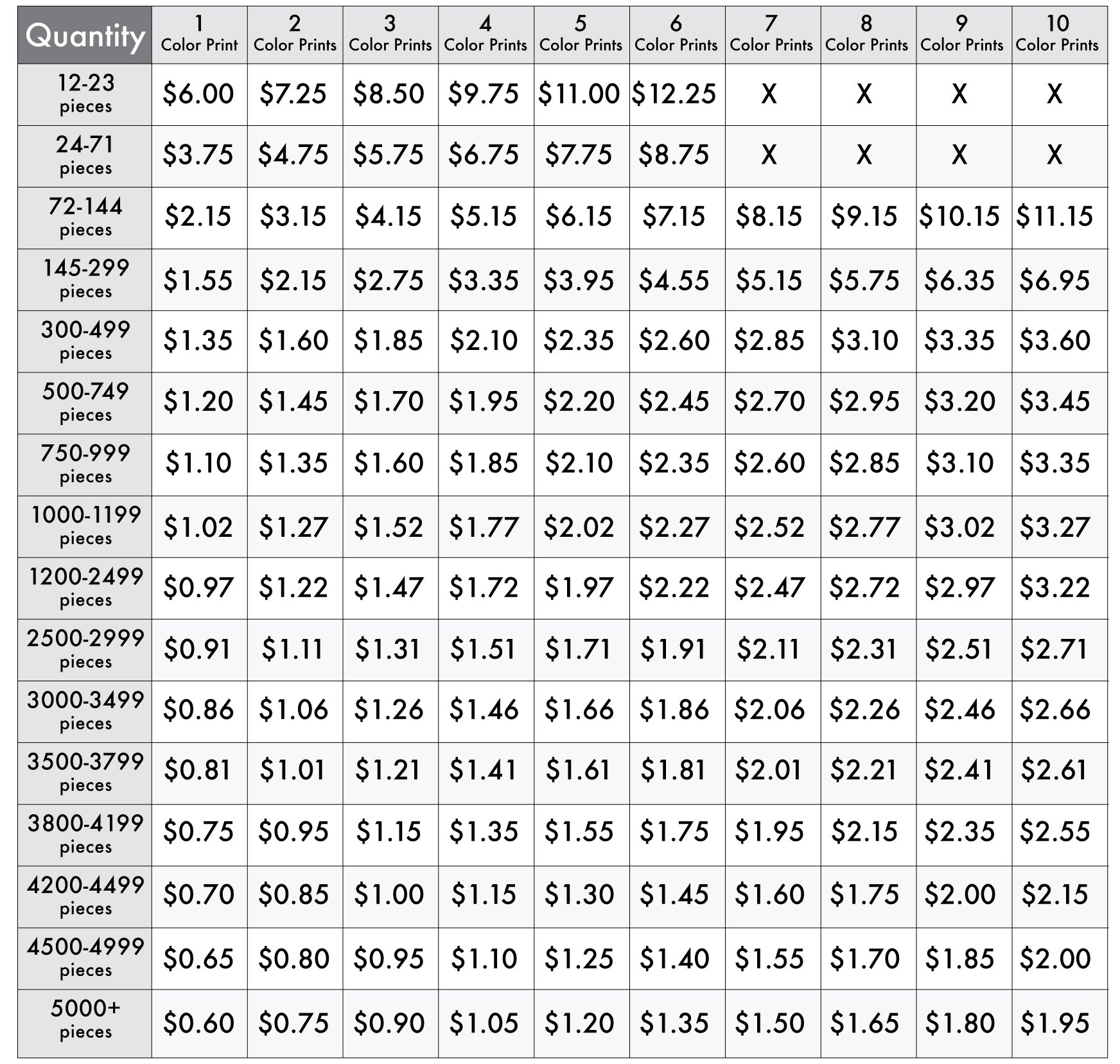

The table below displays typical screen printing costs for different order sizes, garment types, and color counts. These costs are based on basic, standard, and premium screen printing services.

| Order Size | Garment Type | Color Count | Basic | Standard | Premium |

|---|---|---|---|---|---|

| 1-24 units | T-shirts | 1 color | $5-$10 per shirt | $7-$15 per shirt | $10-$20 per shirt |

| 25-99 units | T-shirts | 1 color | $4-$8 per shirt | $6-$12 per shirt | $8-$18 per shirt |

| 100+ units | T-shirts | 1 color | $3-$6 per shirt | $5-$10 per shirt | $7-$15 per shirt |

| 1-24 units | Hoodies | 1 color | $8-$15 per hoodie | $10-$20 per hoodie | $15-$30 per hoodie |

| 25-99 units | Hoodies | 1 color | $7-$12 per hoodie | $9-$18 per hoodie | $12-$25 per hoodie |

| 100+ units | Hoodies | 1 color | $6-$10 per hoodie | $8-$15 per hoodie | $10-$20 per hoodie |

| 1-24 units | T-shirts | 2 colors | $7-$12 per shirt | $9-$18 per shirt | $12-$25 per shirt |

| 25-99 units | T-shirts | 2 colors | $6-$10 per shirt | $8-$15 per shirt | $10-$20 per shirt |

| 100+ units | T-shirts | 2 colors | $5-$8 per shirt | $7-$12 per shirt | $9-$18 per shirt |

Bulk Discounts and Multiple Item Orders

Screen printing companies often offer bulk discounts for larger orders. For example, a company might offer a 10% discount for orders over 100 units, or a 15% discount for orders over 500 units. You can also save money by ordering multiple items at once, such as t-shirts and hoodies.

This allows the printer to set up the screens once and print all the items in one go, which reduces setup costs.

Finding Screen Printing Services

Now that you have a good understanding of the factors that influence screen printing costs, it’s time to start looking for a screen printing service. There are many options available, both online and offline, so you can find the perfect fit for your needs and budget.

Online Resources

Online resources can be a great starting point for finding screen printing services. You can easily search for companies in your area and compare their prices, services, and customer reviews.

- Online Marketplaces:Platforms like Etsy, Amazon Handmade, and Printful offer a wide selection of screen printing services, often with competitive pricing and convenient ordering processes.

- Screen Printing Directories:Websites like ScreenPrinting.com and Printful.com provide comprehensive directories of screen printing companies, allowing you to filter by location, services, and price range.

- Social Media:Search for screen printing companies on social media platforms like Facebook, Instagram, and Twitter. You can often find local businesses with good customer reviews and attractive pricing.

Offline Resources

While online resources offer convenience, offline methods can provide more personalized interactions and opportunities for detailed discussions.

- Local Business Directories:Check out local business directories like the Yellow Pages or Yelp to find screen printing companies in your area.

- Trade Shows and Events:Attending trade shows and events focused on printing and apparel can help you connect with screen printing companies and see their products and services firsthand.

- Networking:Ask friends, family, and colleagues for recommendations on reliable screen printing services. They may have personal experiences and insights to share.

Comparing Screen Printing Companies

Once you’ve compiled a list of potential screen printing companies, it’s essential to compare their offerings to find the best fit for your project. Here’s a table that highlights key factors to consider:

| Company Name | Pricing | Services Offered | Customer Reviews |

|---|---|---|---|

| Company A | $10-$20 per shirt | Screen printing, embroidery, direct-to-garment printing | 4.5 stars on Google Reviews |

| Company B | $15-$30 per shirt | Screen printing, heat transfer, custom designs | 3.8 stars on Yelp |

| Company C | $20-$40 per shirt | High-quality screen printing, fast turnaround times | 4.2 stars on Trustpilot |

Negotiating Prices

Don’t be afraid to negotiate prices with screen printing companies, especially if you have a large order or are willing to work with them on a long-term basis.

- Start with a clear budget:Know how much you’re willing to spend before contacting any companies.

- Shop around:Get quotes from multiple companies to compare prices and services.

- Be flexible with your design:Consider simplifying your design or using a more affordable printing method to reduce costs.

- Ask about discounts:Inquire about discounts for bulk orders, repeat business, or special promotions.

- Negotiate payment terms:Explore options like upfront payments, partial payments, or payment plans.

Getting the Best Value

When choosing a screen printing service, it’s important to prioritize quality and value over just the lowest price.

- Consider the overall quality:Evaluate the quality of the printing, the durability of the ink, and the overall craftsmanship of the finished product.

- Look for experience and expertise:Choose a company with a proven track record of providing high-quality screen printing services.

- Factor in customer service:Look for a company that is responsive, helpful, and willing to go the extra mile to meet your needs.

- Read reviews and testimonials:Check online reviews and testimonials to get a sense of the company’s reputation and customer satisfaction.

Alternative Printing Methods

Screen printing isn’t the only game in town when it comes to customizing apparel and other items. Several other printing methods offer unique advantages and disadvantages, making them suitable for different applications. Let’s explore some popular alternatives and see how they stack up against screen printing in terms of cost, quality, and suitability.

Direct-to-Garment Printing

Direct-to-garment (DTG) printing is a digital printing method that uses specialized inkjet printers to deposit ink directly onto fabric. It’s a versatile technique that allows for intricate designs and full-color prints.

Cost Comparison

- Setup Costs:DTG printing generally requires a lower setup cost compared to screen printing, as it doesn’t involve creating screens. This makes it a good option for small orders or designs with multiple colors.

- Per-Unit Costs:The per-unit cost of DTG printing can be higher than screen printing for larger orders, especially when printing on light-colored fabrics. However, for small orders, DTG printing can be more cost-effective.

Quality and Suitability

- Quality:DTG printing produces high-resolution prints with vibrant colors and excellent detail. The ink penetrates the fabric fibers, resulting in a soft and durable print.

- Suitability:DTG printing is ideal for small orders, intricate designs, and full-color prints. It’s also suitable for printing on light-colored fabrics, as the ink adheres better to white or light-colored materials.

Examples

DTG printing is often used for:

- Custom t-shirts with intricate designs or photographs.

- Small batches of promotional apparel for events or conferences.

- Personalized gifts with unique designs.

Embroidery

Embroidery is a traditional method that uses a needle and thread to create designs on fabric. It offers a unique, tactile, and long-lasting finish.

Cost Comparison

- Setup Costs:Embroidery requires a higher setup cost compared to screen printing or DTG printing, as it involves creating a digital embroidery file and setting up the embroidery machine. This cost can be offset by the ability to create multiple garments with the same design.

- Per-Unit Costs:The per-unit cost of embroidery can be higher than screen printing or DTG printing, especially for intricate designs. However, for large orders, the cost per unit can become competitive.

Quality and Suitability

- Quality:Embroidery produces a high-quality, raised design that is durable and long-lasting. It offers a unique tactile experience and adds a touch of elegance to garments.

- Suitability:Embroidery is best suited for logos, text, and simple designs. It’s ideal for creating a professional and refined look on garments and accessories.

Examples

Embroidery is commonly used for:

- Logos on corporate apparel.

- Names and initials on personalized gifts.

- Decorative elements on hats, bags, and towels.

Heat Transfer

Heat transfer printing involves applying a pre-printed design to fabric using heat and pressure. It’s a versatile method that offers a wide range of design options and is relatively affordable.

Cost Comparison

- Setup Costs:Heat transfer printing requires a lower setup cost compared to screen printing or embroidery, as it involves creating a digital design and printing it onto a transfer sheet. This makes it a good option for small orders or designs with multiple colors.

- Per-Unit Costs:The per-unit cost of heat transfer printing is generally lower than screen printing or embroidery, especially for small orders. However, the cost per unit can increase for larger orders.

Quality and Suitability

- Quality:Heat transfer printing produces a durable and vibrant print with a smooth finish. The quality of the print depends on the quality of the transfer sheet and the printing process.

- Suitability:Heat transfer printing is suitable for a wide range of designs, including full-color prints, photographs, and intricate details. It’s ideal for small orders, promotional items, and personalized gifts.

Examples

Heat transfer printing is commonly used for:

- T-shirts with intricate designs or photographs.

- Promotional items like mugs, tote bags, and hats.

- Personalized gifts with custom designs.

Essential FAQs

What is the minimum order quantity for screen printing?

Minimum order quantities for screen printing can vary depending on the printer and the specific project. Generally, expect minimums ranging from 12 to 24 pieces.

Can I get a sample before placing a large order?

Yes, many screen printing companies offer sample printing services to help you visualize the final product and ensure you’re happy with the quality and design.

What are the different types of inks used in screen printing?

Common ink types include plastisol ink, water-based ink, discharge ink, and glow-in-the-dark ink. Each ink type has its own characteristics and suitability for different fabrics and applications.

How long does it take to get a screen printing order completed?

Turnaround times for screen printing can vary depending on the order size, complexity, and the printer’s workload. Expect lead times of a few days to a couple of weeks.