How much electricity does a 3D printer use? It’s a question that’s increasingly on the minds of makers and enthusiasts as 3D printing gains popularity. The answer, however, isn’t a simple one. It depends on a variety of factors, from the size and model of your printer to the materials you’re using and the complexity of your prints.

Let’s dive into the world of 3D printer energy consumption and explore how it affects your printing experience.

From the type of printing technology employed, like Fused Deposition Modeling (FDM) or Stereolithography (SLA), to the resolution and layer height you choose, every aspect of your 3D printing process contributes to the amount of electricity used. Understanding these factors can help you make informed decisions about your printing projects and minimize your environmental impact.

Factors Influencing Electricity Consumption

The amount of electricity a 3D printer uses is influenced by several factors, including the printer’s size and model, the type of printing material used, the printing resolution and layer height, and the printing technology employed. Understanding these factors can help you choose a 3D printer that meets your needs and budget while being mindful of your energy consumption.

3D Printer Size and Model

The size and model of a 3D printer play a significant role in determining its power consumption. Larger printers generally consume more electricity than smaller ones due to the increased power required to heat the larger print bed and operate the larger motors.

The specific model of the 3D printer also affects its power consumption, as different models may have varying motor sizes, heating elements, and control systems. For example, a high-end industrial 3D printer designed for large-scale production will consume more electricity than a small desktop 3D printer intended for hobbyists.

Measuring Electricity Consumption

To accurately assess how much electricity your 3D printer uses, you need to measure its power consumption. This information is crucial for understanding the energy cost associated with 3D printing and identifying potential areas for improvement.

Using a Power Meter

A power meter is an essential tool for measuring the electricity consumption of your 3D printer. It plugs into an electrical outlet and has a socket for you to plug your printer into. The meter monitors the flow of electricity and displays the real-time power usage in watts (W).

- Most power meters come with a digital display that shows the current power consumption, as well as accumulated energy usage in kilowatt-hours (kWh).

- Some power meters can be connected to your computer or smartphone via Bluetooth or Wi-Fi, allowing you to monitor your printer’s energy consumption remotely.

Kilowatt-Hours (kWh)

Kilowatt-hours (kWh) are the standard unit for measuring energy consumption. One kilowatt-hour represents the amount of energy used by a 1-kilowatt appliance running for one hour.

kWh = (kW x hours) / 1000

For example, if your 3D printer uses 200 watts (0.2 kW) and runs for 10 hours, its total energy consumption would be 2 kWh.

kWh = (0.2 kW x 10 hours) / 1000

This information is essential for calculating the cost of running your 3D printer, as your electricity bill is typically based on kWh consumption.

Reducing Electricity Consumption

While 3D printing offers numerous benefits, it’s essential to be mindful of its energy consumption. By implementing energy-saving techniques, you can reduce your electricity bill and minimize your environmental impact.

The amount of electricity a 3D printer uses depends on its size and features. If you’re curious about a specific model, it’s best to check the manufacturer’s specifications. You can also find information about how much power a 3D printer uses by searching online.

For example, if you’re looking to find out about a particular company like Wander Prints, you can search for “how much electricity does a Wander Prints 3D printer use” or find out where is Wander Prints located to see if they have any information on their website.

This will help you determine if their 3D printers are energy efficient.

- Reduce idle time: Ensure your printer is only powered on when actively printing. Switch it off or put it into sleep mode when not in use.

- Use energy-efficient materials: Opt for materials that require less energy to melt and extrude, such as PLA or PETG, instead of high-temperature materials like ABS or nylon.

- Optimize print settings: Experiment with print settings such as layer height, infill density, and printing speed to find a balance between print quality and energy consumption.

- Utilize print bed temperature control: Only heat the print bed to the required temperature for the specific material you’re using. Avoid unnecessarily high temperatures.

- Upgrade to an energy-efficient model: Some 3D printers are designed with energy efficiency in mind, incorporating features like automatic shut-off mechanisms or optimized power management systems.

Estimating Electricity Costs

Understanding the electricity consumption of a 3D printer is crucial for determining its overall operating cost. By calculating the estimated electricity cost, you can make informed decisions about the financial implications of using a 3D printer for your projects.

Calculating Estimated Electricity Costs, How much electricity does a 3d printer use

The estimated cost of electricity used by a 3D printer can be calculated using a simple formula:

Cost = Power Consumption (watts) x Printing Time (hours) x Electricity Rate ($/kWh)

For example, if your 3D printer consumes 200 watts of power and you print for 10 hours at an electricity rate of $0.15/kWh, the estimated cost would be:

Cost = 200 watts x 10 hours x $0.15/kWh = $3.00

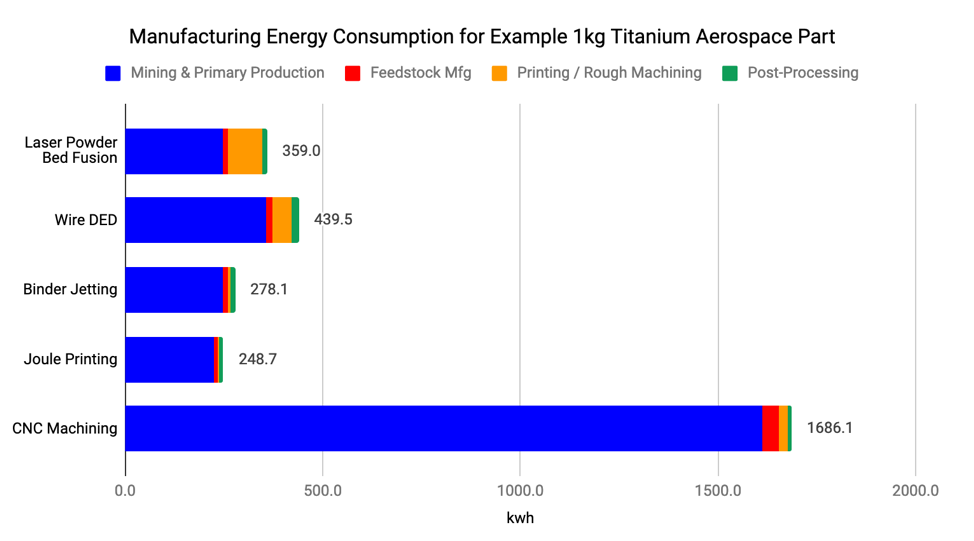

Comparing Electricity Costs with Other Manufacturing Methods

D printing offers several advantages over traditional manufacturing methods, including lower material waste and reduced tooling costs. However, it’s important to consider the electricity consumption and associated costs. In general, 3D printing tends to consume less energy than traditional manufacturing methods like injection molding or CNC machining.

This is because 3D printing involves additive manufacturing, where material is built up layer by layer, resulting in less material waste.

Impact of Electricity Costs on Overall Project Costs

The electricity cost of 3D printing can significantly impact the overall project cost, especially for large-scale projects or projects involving extended printing times. It’s essential to factor in the electricity cost when estimating the total cost of a 3D printing project.

Electricity Costs for Different 3D Printer Models and Printing Durations

The following table shows the estimated electricity costs for different 3D printer models and printing durations, assuming an electricity rate of $0.15/kWh:

| 3D Printer Model | Power Consumption (watts) | Printing Time (hours) | Estimated Electricity Cost ($) |

|---|---|---|---|

| Creality Ender 3 | 150 | 10 | $2.25 |

| Prusa i3 MK3S | 250 | 20 | $7.50 |

| Ultimaker Cura | 350 | 30 | $15.75 |

Environmental Impact

While 3D printing offers numerous advantages, it’s crucial to consider its environmental footprint. The energy consumed by 3D printers contributes to greenhouse gas emissions and climate change. Understanding the environmental impact of 3D printing is essential for making informed decisions and exploring sustainable practices.

Carbon Footprint of 3D Printing

The carbon footprint of 3D printing is influenced by various factors, including the type of printer, the materials used, and the energy source used to power the printer. The energy required to operate a 3D printer contributes significantly to its carbon footprint.

The manufacturing process of 3D printing materials also contributes to greenhouse gas emissions.

Alternative Energy Sources for 3D Printing

Using renewable energy sources to power 3D printers can significantly reduce their environmental impact. Solar and wind energy are promising alternatives to traditional fossil fuels.

Solar Energy

Solar panels can be used to generate electricity from sunlight, providing a clean and sustainable energy source for 3D printing. Installing solar panels on the roof of a workshop or home can reduce reliance on the grid and minimize carbon emissions.

Wind Energy

Wind turbines can harness the power of wind to generate electricity. Wind energy is a clean and renewable source that can be used to power 3D printers, especially in areas with consistent wind patterns.

Benefits of Renewable Energy Sources for 3D Printing

Utilizing renewable energy sources for 3D printing offers numerous benefits:

- Reduced Carbon Emissions: By relying on solar and wind energy, 3D printing operations can significantly reduce their greenhouse gas emissions, contributing to a cleaner environment.

- Energy Independence: Renewable energy sources can provide a degree of energy independence, reducing reliance on fossil fuels and volatile energy markets.

- Cost Savings: In the long run, using renewable energy sources can lead to cost savings, as the fuel for these sources is free and readily available.

User Queries: How Much Electricity Does A 3d Printer Use

How much does it cost to run a 3D printer per hour?

The cost per hour varies significantly based on the printer’s power consumption and your local electricity rates. A rough estimate is between $0.10 to $0.50 per hour.

Can I use solar power to run my 3D printer?

Yes, you can! Using solar panels to power your 3D printer is a great way to reduce your carbon footprint. You’ll need to consider the printer’s power requirements and the output of your solar panels.

What are the most energy-efficient 3D printer models?

Look for models with lower power consumption ratings and features like automatic shut-off modes. Research specific models and compare their energy efficiency.