How to clean a 3D printer nozzle is a question every 3D printing enthusiast faces. A clogged nozzle can lead to frustrating printing issues, from inconsistent filament flow to complete print failures. This guide provides a comprehensive look at cleaning your nozzle, covering everything from identifying the problem to preventative measures.

Understanding the nozzle’s function, recognizing signs of a clogged nozzle, and choosing the right cleaning method are crucial for maintaining your 3D printer’s performance. We’ll explore various cleaning techniques, including cold pulls, hot pulls, and chemical cleaning, and discuss the tools and materials you’ll need.

Additionally, we’ll delve into preventative measures to minimize clogging and troubleshoot common nozzle problems.

Understanding the Nozzle and Its Function: How To Clean A 3d Printer Nozzle

The nozzle is a crucial component in 3D printing, responsible for extruding the molten filament and shaping the final printed object. Its design and material play a significant role in print quality and overall performance.

Nozzle Types

Nozzles come in various shapes and sizes, each designed for specific applications and materials.

- Standard Nozzles:These are the most common type, with a circular opening for extruding filament. They are versatile and suitable for a wide range of materials.

- Specialty Nozzles:These nozzles are designed for specific tasks or materials, such as:

- Multi-nozzle:Allows for simultaneous extrusion of multiple filaments, creating complex patterns and colors.

- Wide-angle nozzles:Used for creating wider lines and smoother surfaces, ideal for large-scale prints.

- Low-flow nozzles:Designed for precise control and detail, suitable for intricate prints and small features.

Nozzle Materials

Nozzles are typically made from materials that can withstand high temperatures and resist wear and tear.

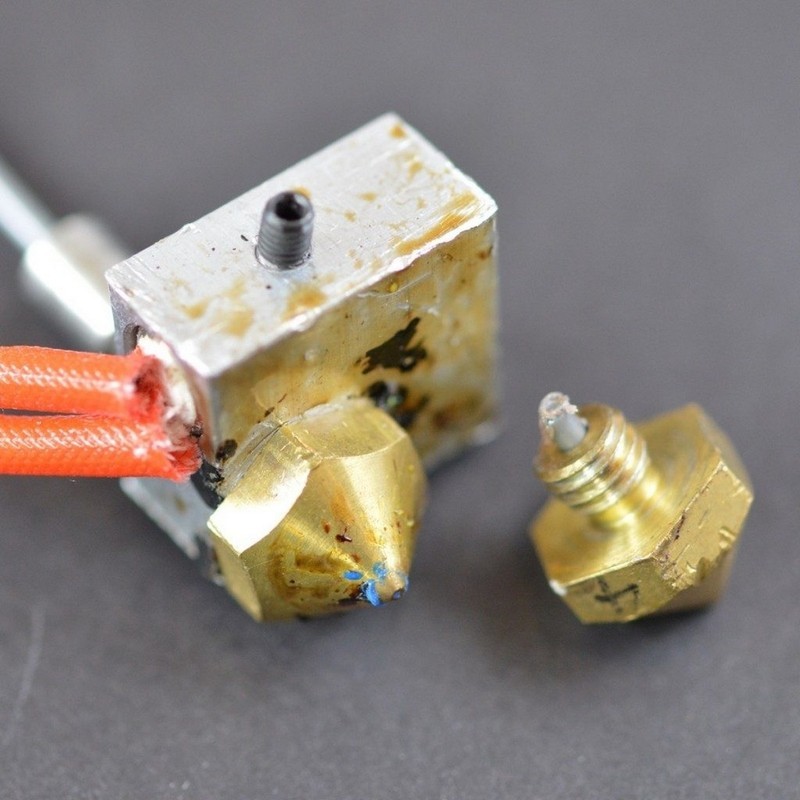

- Brass:A common and affordable material, offering good heat conductivity and wear resistance. However, it can be prone to corrosion and may require frequent cleaning.

- Stainless Steel:Offers superior corrosion resistance and durability compared to brass. It is a good choice for high-temperature applications and abrasive materials.

- Tungsten Carbide:A highly durable and wear-resistant material, ideal for printing abrasive materials like carbon fiber or metal filaments. However, it is more expensive than brass or stainless steel.

- Ruby:A very hard and wear-resistant material, offering exceptional durability and heat resistance. It is often used for printing abrasive materials and high-temperature applications.

Identifying the Need for Cleaning

Knowing when to clean your 3D printer nozzle is crucial for maintaining print quality and preventing damage to your printer. A clogged nozzle can lead to various issues, impacting your printing experience.

Signs of a Clogged Nozzle

A clogged nozzle can manifest in several ways, indicating the need for cleaning. Here are some common signs:

- Filament not extruding:This is the most obvious sign. If your printer fails to extrude filament, the nozzle is likely clogged.

- Uneven extrusion:You may notice inconsistent filament flow, resulting in thin or patchy prints.

- Filament oozing:Excess filament may ooze from the nozzle, leading to messy prints.

- Clicking noises:Your printer may make clicking sounds as the extruder motor struggles to push filament through the nozzle.

- Burning smell:A burnt smell can indicate filament being melted in the nozzle but not being extruded. This can damage the nozzle.

Common Issues Caused by a Dirty Nozzle

A dirty nozzle can cause a range of printing problems, affecting the quality and efficiency of your 3D prints.

- Under-extrusion:A clogged nozzle restricts filament flow, leading to thin or incomplete prints.

- Over-extrusion:A partially clogged nozzle can cause inconsistent filament flow, resulting in uneven prints.

- Stringing:Excess filament may drip from the nozzle, creating unsightly strings on your prints.

- Blobs:A clogged nozzle can cause filament to build up, forming blobs on your prints.

- Nozzle damage:If filament is stuck in the nozzle, it can damage the nozzle and require replacement.

Determining Cleaning Frequency

The frequency of cleaning your nozzle depends on several factors, including the type of filament used and the printer’s usage.

- Filament type:Abrasive filaments like wood or carbon fiber can clog the nozzle faster than standard PLA or ABS.

- Printing frequency:The more you print, the more likely your nozzle will get dirty.

- Temperature:Higher temperatures can increase the likelihood of filament buildup in the nozzle.

- Maintenance:Regular maintenance, such as wiping down the nozzle after each print, can help prevent clogs.

It’s generally a good practice to clean your nozzle every 5-10 hours of printing, especially when using abrasive filaments. However, if you notice any signs of a clogged nozzle, it’s best to clean it immediately.

Cleaning Methods

Cleaning your 3D printer nozzle is crucial for maintaining print quality and preventing clogs. Different methods exist, each with its advantages and disadvantages. Choosing the right method depends on the severity of the clog, the type of filament used, and your comfort level with different techniques.

Cold Pull Method

The cold pull method is a simple and effective way to remove minor clogs. It involves using the printer’s heat to melt the filament and then pulling it out of the nozzle.

- Heat the nozzle to the filament’s printing temperature.

- Load a new filament into the printer.

- Slowly extrude the filament until you see a small amount of melted plastic coming out of the nozzle.

- Carefully pull the filament back, allowing the melted plastic to solidify within the nozzle.

- Once the filament is cool, pull it out of the nozzle, removing the clog.

Safety Precautions:

- Wear safety glasses to protect your eyes from hot plastic.

- Be careful not to burn yourself on the hot nozzle.

Hot Pull Method

The hot pull method is similar to the cold pull method, but it involves heating the filament to a higher temperature. This can be more effective for removing stubborn clogs.

- Heat the nozzle to a temperature slightly higher than the filament’s printing temperature.

- Load a new filament into the printer.

- Slowly extrude the filament until you see a small amount of melted plastic coming out of the nozzle.

- Carefully pull the filament back, allowing the melted plastic to solidify within the nozzle.

- Once the filament is cool, pull it out of the nozzle, removing the clog.

Safety Precautions:

- Wear safety glasses to protect your eyes from hot plastic.

- Be careful not to burn yourself on the hot nozzle.

- Use caution when working with high temperatures.

Chemical Cleaning

Chemical cleaning involves using solvents to dissolve and remove clogs. This method is typically used for stubborn clogs that cannot be removed with cold or hot pulls.

- Remove the nozzle from the printer.

- Soak the nozzle in a solvent appropriate for the filament material. For example, acetone is commonly used for PLA and ABS.

- Allow the nozzle to soak for several minutes, or until the clog dissolves.

- Rinse the nozzle with clean water and dry it thoroughly.

- Reinstall the nozzle on the printer.

Safety Precautions:

- Work in a well-ventilated area to avoid inhaling fumes.

- Wear gloves to protect your hands from the solvent.

- Use caution when handling solvents, as they can be flammable and harmful to skin.

- Dispose of solvents properly, following local regulations.

Comparing Cleaning Methods

Here’s a table comparing and contrasting different cleaning methods:

| Method | Advantages | Disadvantages |

|---|---|---|

| Cold Pull | Simple and effective for minor clogs | May not be effective for stubborn clogs |

| Hot Pull | More effective for stubborn clogs than cold pull | Requires higher temperatures, which can be dangerous |

| Chemical Cleaning | Most effective for stubborn clogs | Can be dangerous if not handled properly |

Tools and Materials

Cleaning your 3D printer nozzle requires specific tools and materials to ensure a smooth and effective process. The right tools will make the cleaning process easier and prevent damage to your nozzle.

Essential Tools

- Nozzle Wrench:A nozzle wrench is a specialized tool designed to tighten and loosen the nozzle on your 3D printer. It features a specific size and shape that fits perfectly onto the nozzle, allowing you to remove and replace it securely.

These wrenches are usually made of durable materials like steel or aluminum to withstand the high temperatures involved in 3D printing.

- Needle-Nose Pliers:Needle-nose pliers are essential for gripping and manipulating small objects, especially when working with delicate parts like the nozzle. They provide precise control and can help you remove stubborn debris or filament from the nozzle opening.

- Wire Brush:A wire brush, preferably with fine bristles, is used to clean the inside of the nozzle. The bristles can effectively remove carbon buildup and other residues that may have accumulated during printing. A brass brush is a good choice for cleaning brass nozzles, as it’s less likely to scratch the metal.

Cleaning your 3D printer nozzle is essential for maintaining print quality. A clogged nozzle can cause messy prints and even damage your printer. If you’re tired of printing out your manuscript just to read it, you can check out this article on how to read your manuscripy without printing.

Once you’ve got your manuscript reading sorted, you can get back to cleaning that nozzle and printing out some awesome creations!

- Screwdriver:A small screwdriver is necessary to loosen or tighten any screws holding the nozzle in place. The size of the screwdriver will depend on the specific design of your 3D printer.

- Heat Gun:A heat gun can be helpful for softening stubborn filament residue or carbon buildup inside the nozzle. Applying heat allows the material to become more pliable and easier to remove. However, be cautious and use low heat settings to avoid damaging the nozzle or surrounding components.

Cleaning Materials

- Isopropyl Alcohol (IPA):IPA is a common solvent used to clean 3D printer nozzles. It effectively dissolves oils, grease, and other contaminants that can clog the nozzle. IPA is readily available at most hardware stores or online.

- Acetone:Acetone is a stronger solvent than IPA and can be used to remove stubborn residue or hardened filament. However, be cautious as acetone can damage certain plastics and should be used sparingly. Make sure your nozzle material is compatible with acetone before using it.

- Cleaning Rags:Clean rags or paper towels are essential for wiping away cleaning solutions and debris from the nozzle and surrounding areas. Use clean rags to avoid introducing new contaminants.

- Cotton Swabs:Cotton swabs can be used to apply cleaning solutions to the nozzle opening and to reach tight spots where a brush may not fit. Use a fresh swab for each application to avoid spreading contaminants.

Alternative Options, How to clean a 3d printer nozzle

- Alternative to Nozzle Wrench:If you don’t have a dedicated nozzle wrench, you can use adjustable pliers or a socket wrench with a suitable adapter. However, be extremely careful not to overtighten the nozzle, as this can damage the threads.

- Alternative to Wire Brush:If you don’t have a wire brush, you can use a small piece of wire or a thin metal rod to clean the nozzle opening. Be careful not to scratch the inside of the nozzle. You can also try using a thin needle or a sewing pin for delicate cleaning.

- Alternative to Heat Gun:If you don’t have a heat gun, you can try using a lighter or a hairdryer to apply heat to the nozzle. However, be extremely cautious as these methods can be more difficult to control and can potentially damage the nozzle or surrounding components.

Preventing Nozzle Clogging

A clean nozzle is crucial for smooth and reliable 3D printing. Preventing clogging in the first place is the best approach, as cleaning can be time-consuming and may even damage the nozzle if done improperly.

Using High-Quality Filament

The quality of filament plays a significant role in preventing nozzle clogging. High-quality filament is less likely to contain impurities or moisture that can cause blockages.

- Look for filament from reputable manufacturers with good reviews and certifications.

- Avoid storing filament in humid environments, as moisture can degrade the filament and lead to clogging.

- Use a filament dryer to remove moisture from filament, especially if you live in a humid climate.

Proper Printer Maintenance

Regular maintenance is essential for keeping your 3D printer in optimal condition and preventing nozzle clogging.

- Clean the nozzle regularly using a brass brush or a specialized nozzle cleaning tool.

- Inspect the nozzle for any signs of wear or damage, such as scratches or burrs.

- Replace the nozzle if it is damaged or worn out.

- Ensure that the extruder mechanism is clean and free of debris.

- Calibrate the extruder regularly to ensure proper filament feed and prevent over-extrusion.

Printing Practices

Your printing practices can also influence nozzle clogging.

- Use the correct temperature for your filament. Refer to the manufacturer’s recommendations for the ideal printing temperature for your filament type.

- Avoid printing too fast, as this can cause the filament to cool too quickly and lead to clogs.

- Use a retraction setting to prevent filament from oozing out of the nozzle during pauses or layer changes.

- Keep the print bed level to ensure a good first layer and prevent filament from being dragged across the nozzle.

- Avoid printing in a dusty or dirty environment. Dust and debris can easily find their way into the nozzle and cause clogs.

Troubleshooting Nozzle Problems

Nozzle issues can be a frustrating part of 3D printing. You might encounter problems like inconsistent prints, clogging, or even the nozzle detaching. Luckily, many of these issues can be resolved with some troubleshooting steps.

Common Nozzle Problems and Their Causes

Nozzle problems can stem from a variety of sources. Understanding the common issues and their causes can help you diagnose and fix them effectively.

- Clogging:This is the most common nozzle problem. It occurs when filament gets stuck inside the nozzle, preventing it from flowing smoothly. The most common cause is using the wrong filament type for your nozzle or using a nozzle that is too small for the filament.

Other causes include:

- Using filament that is too old or has been exposed to moisture.

- Not cleaning the nozzle regularly.

- Having a loose or damaged nozzle.

- Inconsistent Prints:This can be caused by a variety of factors, including a clogged nozzle, but also by:

- Incorrect temperature settings.

- A loose or damaged nozzle.

- Problems with the filament feed.

- Nozzle Detachment:This usually happens when the nozzle is not properly secured to the hot end. It can also occur if the nozzle is damaged or if the hot end itself is loose.

Troubleshooting Nozzle Issues

Once you’ve identified the problem, you can begin troubleshooting. Here’s a breakdown of some common issues and their solutions:

Clogged Nozzle

- Clean the nozzle:The first step is to try cleaning the nozzle. Use a needle or a small wire brush to remove any filament that may be blocking the nozzle opening. You can also try using a small amount of alcohol to dissolve any remaining filament.

If the nozzle is still clogged, you can try heating the nozzle to a high temperature (around 200°C) for a few minutes. This may help to melt the filament and allow it to flow through the nozzle again.

- Replace the nozzle:If cleaning the nozzle doesn’t work, you may need to replace it. This is especially true if the nozzle is damaged or if it’s too small for the filament you’re using.

Inconsistent Prints

- Check the temperature settings:Make sure the temperature settings for your printer are correct for the filament you’re using. You can find recommended temperature settings in the filament’s documentation or online.

- Check the nozzle:Make sure the nozzle is properly secured to the hot end. If it’s loose, tighten it. If it’s damaged, you’ll need to replace it.

- Check the filament feed:Make sure the filament is feeding smoothly through the extruder. If it’s not, you may need to adjust the tension on the filament feed or clean the feed mechanism.

Nozzle Detachment

- Tighten the nozzle:If the nozzle is loose, simply tighten it. Be careful not to overtighten it, as this could damage the nozzle or the hot end.

- Replace the nozzle:If the nozzle is damaged, you’ll need to replace it.

- Check the hot end:If the hot end is loose, you may need to tighten it or replace it.

Consulting the Printer’s Manual

Always remember to consult your printer’s manual for specific troubleshooting steps. The manual will provide detailed information about your printer’s features and how to resolve common problems.

Key Questions Answered

What are the signs of a clogged nozzle?

A clogged nozzle can cause inconsistent filament flow, thin or weak prints, skipped layers, or even complete print failures. You might also notice filament oozing from the nozzle or burning at the tip.

How often should I clean my nozzle?

The frequency of cleaning depends on the type of filament you use, the frequency of printing, and the overall wear and tear on your nozzle. It’s generally recommended to clean your nozzle every few prints or after using abrasive filaments.

Can I use alcohol to clean my nozzle?

Isopropyl alcohol is commonly used to clean 3D printer nozzles. However, it’s important to note that alcohol can damage certain types of nozzles, such as those made of brass or copper. Always consult the manufacturer’s recommendations for your specific nozzle.