How to smooth top layer 3D print Bambu takes center stage as we delve into the world of achieving pristine finishes on your 3D prints. Bambu Lab printers are known for their exceptional capabilities, offering a unique blend of features that contribute to superior surface quality.

From understanding the printer’s nuances to mastering printing techniques, this guide provides a comprehensive approach to transforming your 3D prints from rough to remarkably smooth.

We’ll explore the key factors influencing surface smoothness, including filament selection, nozzle size, and printing parameters. Discover how to prepare your models, set up your Bambu Lab printer, and utilize post-processing techniques to achieve the desired finish. We’ll also address common printing issues that can affect surface quality, offering practical solutions to overcome these challenges.

Join us as we unravel the secrets to achieving those flawless 3D prints you’ve always dreamed of.

Understanding the Bambu Lab 3D Printer

Bambu Lab 3D printers are known for their ability to produce smooth surfaces on prints. They offer a combination of features and technologies that contribute to this quality.

Unique Features for Smooth Surfaces

Bambu Lab 3D printers have several unique features that directly contribute to the smoothness of the printed surface. These features are:

- Direct Drive Extruder:This type of extruder reduces the distance between the nozzle and the print bed, resulting in less stringing and better surface quality. It ensures precise filament deposition, minimizing gaps and imperfections.

- High-Precision Linear Rails:These rails provide smooth and accurate movement of the print head, reducing vibration and ensuring consistent layer adhesion. This precision in movement minimizes inconsistencies in layer thickness, resulting in a smoother surface.

- Advanced Firmware:The firmware in Bambu Lab printers offers a variety of settings and features specifically designed to improve surface smoothness. For instance, the “Adaptive Layering” feature adjusts layer height based on the print geometry, minimizing layer lines and creating a smoother finish.

Advantages of Bambu Lab Printers for Smooth Surfaces

Bambu Lab 3D printers offer several advantages when it comes to achieving smooth surfaces.

- Reduced Stringing and Oozing:The direct drive extruder minimizes filament stringing and oozing, resulting in cleaner prints with fewer imperfections. This is particularly beneficial for achieving smooth surfaces, as it prevents the formation of unsightly strings and blobs on the print.

- Improved Layer Adhesion:The high-precision linear rails ensure consistent layer adhesion, reducing the likelihood of layer delamination and improving overall surface smoothness.

- Enhanced Detail Resolution:The precision of the Bambu Lab printers allows for finer detail resolution, resulting in smoother surfaces and sharper features. This is crucial for applications requiring high-quality finishes, such as models and prototypes.

Challenges Affecting Surface Smoothness

While Bambu Lab printers are known for their smooth surface quality, certain challenges can affect the final finish.

- Filament Quality:The quality of the filament used plays a significant role in surface smoothness. Filaments with inconsistencies in diameter or material composition can lead to uneven layer heights and visible lines. It’s essential to use high-quality filament that is specifically designed for smooth prints.

- Print Settings:Incorrect print settings, such as nozzle temperature, print speed, and retraction settings, can significantly affect surface smoothness. It’s crucial to experiment with these settings to find the optimal configuration for achieving the desired finish.

- Print Bed Adhesion:Poor bed adhesion can lead to warping and lifting of the print, resulting in an uneven surface. It’s essential to ensure proper bed leveling and the use of appropriate adhesion materials to prevent these issues.

Factors Influencing Surface Smoothness

Achieving a smooth surface finish on your 3D prints is a key aspect of creating high-quality, professional-looking models. Several factors contribute to surface smoothness, and understanding these factors allows you to fine-tune your printing parameters for optimal results.

Printing Parameters

Printing parameters significantly influence the surface smoothness of your 3D prints. By adjusting these settings, you can minimize layer lines and create a smoother, more aesthetically pleasing finish.

- Layer Height:Reducing the layer height creates thinner layers, resulting in smoother surfaces. However, this also increases printing time and may increase the risk of clogging. A good starting point for smoother prints is a layer height of 0.1 mm or lower.

- Print Speed:Slower print speeds allow the filament to cool and solidify more evenly, reducing layer lines and creating smoother surfaces. However, slower speeds can also increase printing time.

- Infill Density:While infill density primarily affects the strength and weight of your print, it can also influence surface smoothness. Higher infill densities can lead to a smoother surface, especially when using a lower layer height.

- Retraction Settings:Retraction settings help prevent stringing and oozing by retracting the filament when the nozzle moves between print points. Proper retraction settings can significantly improve surface smoothness, especially on overhangs and intricate details.

- Temperature:The print temperature plays a crucial role in filament flow and adhesion. The optimal temperature for your filament can vary, but finding the right temperature can minimize layer lines and create a smoother surface.

- Cooling Fan Speed:The cooling fan helps solidify the filament quickly, reducing layer lines and improving surface smoothness. However, excessive cooling can lead to warping or cracking, so finding the right balance is essential.

Filament Type and Properties

The type of filament you use has a significant impact on surface smoothness. Different filaments have unique properties that influence their ability to create smooth surfaces.

- PLA:PLA is a popular filament known for its ease of printing and good surface finish. It typically produces smooth surfaces, especially when printed at lower layer heights.

- ABS:ABS is another common filament known for its strength and durability. However, it tends to have a more textured surface compared to PLA, especially when printed at higher temperatures.

- PETG:PETG is a versatile filament that offers a good balance of strength, flexibility, and surface finish. It often produces smoother surfaces than ABS but may require slightly higher temperatures.

- Nylon:Nylon is a strong and flexible filament that can be challenging to print smoothly due to its tendency to absorb moisture. Proper drying and careful printing settings are crucial for achieving a smooth finish with nylon.

Nozzle Size

The size of the nozzle you use can also affect surface smoothness. Larger nozzles can produce faster prints with thicker layers, resulting in a less smooth finish. Smaller nozzles, on the other hand, create thinner layers and smoother surfaces, but they may require slower print speeds.

- Smaller Nozzles:Smaller nozzles, such as 0.4 mm or 0.3 mm, produce finer details and smoother surfaces, especially at lower layer heights. However, smaller nozzles can be more prone to clogging and may require slower print speeds.

- Larger Nozzles:Larger nozzles, such as 0.6 mm or 0.8 mm, allow for faster printing and thicker layers. This can lead to a less smooth finish, but it can be beneficial for large prints or prints with minimal detail.

Pre-Printing Preparation

Before you hit “print” on your Bambu Lab 3D printer, there are a few crucial steps you need to take to ensure a smooth surface finish. This stage involves preparing your 3D model and setting up your printer for optimal performance.

Model Preparation

Preparing your 3D model is essential for achieving a smooth surface finish. It ensures that your print is well-defined, free from errors, and ready for the printing process.

- Optimize for Print Resolution:Before printing, consider the desired level of detail for your model. For a smooth finish, a higher resolution (more pixels per inch) is generally preferred. This creates a smoother, more refined surface. If you’re working with a complex design, consider using a mesh reduction tool to simplify the model and improve print quality.

- Check for Errors and Gaps:Use a 3D modeling software to carefully inspect your model for any errors, such as holes, gaps, or overlapping faces. These issues can disrupt the printing process and result in an uneven surface. Use tools like “repair” or “inspect” in your software to identify and fix these problems.

If you’re working with a complex model, consider using a mesh repair tool to fix any errors or inconsistencies.

- Optimize Print Orientation:The orientation of your model on the print bed can significantly impact surface smoothness. Choose an orientation that minimizes the amount of overhangs or unsupported areas, as these can be prone to imperfections. Consider using supports for complex geometries or overhangs to ensure proper print formation and prevent sagging.

A common approach is to orient the model with its flattest surface facing the print bed, reducing the amount of overhangs and promoting better adhesion.

- Scale Model to Desired Size:Ensure your model is scaled to the correct size for your intended use. If you need to adjust the size, use your 3D modeling software to scale it accordingly.

- Save Model in STL Format:The STL (Stereolithography) format is a standard file format for 3D printing. Save your model in this format to ensure compatibility with your Bambu Lab 3D printer.

Printer Setup for Smooth Printing

Setting up your Bambu Lab 3D printer correctly is crucial for achieving a smooth surface finish. It involves configuring the printer settings and optimizing the print environment.

- Clean Print Bed and Nozzle:Before printing, ensure that your print bed and nozzle are clean and free from any debris or residue. This prevents imperfections and ensures proper adhesion. Use a microfiber cloth or a specialized cleaning solution to thoroughly clean the print bed and nozzle.

If necessary, you can use a nozzle cleaning tool to remove any clogs or debris from the nozzle.

- Level Print Bed:A properly leveled print bed is essential for achieving a smooth surface finish. This ensures that the model is in perfect contact with the print bed throughout the printing process. Use the Bambu Lab software’s bed leveling feature to accurately level the print bed.

This involves adjusting the print bed’s height relative to the nozzle to ensure consistent contact across the entire print surface.

- Calibrate Extruder:Calibrating the extruder ensures that the filament is extruded at the correct rate, which is essential for consistent layer deposition and smooth surface finish. The Bambu Lab software provides a calibration tool for this purpose. Follow the on-screen instructions to calibrate the extruder, ensuring accurate filament flow.

- Select Appropriate Print Settings:The Bambu Lab software offers a wide range of print settings, including layer height, infill density, and nozzle temperature. Choose settings that are appropriate for your model and desired surface finish. Experiment with different settings to find the optimal combination for your specific needs.

- Layer Height:A lower layer height (e.g., 0.1 mm) typically results in a smoother surface finish. However, it also increases the printing time.

- Infill Density:Infill density refers to the amount of material inside the printed object. A higher infill density (e.g., 100%) provides more strength and support but can also increase the printing time. For a smooth surface, consider using a lower infill density (e.g., 20%) for the outer layers and a higher infill density for the internal structure.

- Nozzle Temperature:The nozzle temperature should be optimized for the specific filament being used. Refer to the filament manufacturer’s recommendations for the optimal printing temperature. Too high a temperature can lead to warping or stringing, while too low a temperature can cause under-extrusion or poor adhesion.

- Printing Speed:A slower printing speed can help improve surface smoothness, as it allows for more precise layer deposition. However, it also increases the printing time.

- Cooling Fan:The cooling fan helps to cool the printed layers, preventing warping or sagging. Experiment with different fan speeds to find the optimal setting for your model and filament.

- Prepare the Print Environment:The printing environment can also impact surface smoothness. A stable, dust-free environment with consistent temperature and humidity is ideal. Ensure that your printer is placed on a stable surface, away from drafts or direct sunlight.

Bed Adhesion, How to smooth top layer 3d print bambu

Proper bed adhesion is essential for a smooth surface finish. It ensures that the first layer of the print adheres securely to the print bed, preventing warping or lifting during the printing process.

- Use Adhesion Aids:If you experience adhesion issues, consider using adhesion aids such as glue stick, hairspray, or a build plate adhesive sheet. These aids can improve the adhesion between the print bed and the first layer of the print.

- Clean Print Bed Thoroughly:Before applying any adhesion aids, ensure that the print bed is thoroughly clean and free from any debris or residue. This ensures that the adhesion aid adheres properly to the print bed.

- Print Bed Temperature:Adjusting the print bed temperature can also improve adhesion. Consult the filament manufacturer’s recommendations for the optimal print bed temperature.

Printing Techniques for Smooth Surfaces: How To Smooth Top Layer 3d Print Bambu

Now that you have a good understanding of your printer and the factors that affect surface smoothness, let’s dive into some printing techniques that can help you achieve a polished finish.

Infill Patterns and Surface Smoothness

Infill patterns are the internal structures of your 3D print, and they play a significant role in surface smoothness.

- Solid Infill: Provides the most robust and smooth surface, but it uses the most material.

- Honeycomb Infill: Offers a balance of strength and surface smoothness while using less material than solid infill.

- Grid Infill: A common choice, it’s a simple pattern that provides good strength but can result in a slightly rougher surface.

- Gyroid Infill: This complex pattern is known for its high strength-to-weight ratio and can produce a smooth surface, but it may be more time-consuming to print.

Experiment with different infill patterns to find the best balance of strength, smoothness, and print time for your specific needs.

Layer Height and Surface Quality

Layer height refers to the thickness of each individual layer of plastic that your 3D printer deposits. It’s a crucial factor influencing surface smoothness.

- Lower Layer Heights: Produce smoother surfaces but can increase print time and material usage.

- Higher Layer Heights: Can lead to a more noticeable layer pattern, especially on flat surfaces. However, they can speed up printing and save material.

The ideal layer height will depend on the desired level of detail and the size of your print.

Printing Speed and Surface Smoothness

Printing speed is another factor that can impact surface quality.

| Printing Speed | Effect on Surface Smoothness |

|---|---|

| Slow | Generally results in smoother surfaces with less visible layer lines. |

| Medium | A good balance between print time and surface quality. |

| Fast | May lead to visible layer lines and a slightly rougher surface. |

The optimal printing speed will vary based on your printer, filament, and desired surface quality.

Smoothing the top layer of your 3D print on your Bambu Lab printer is all about finding the right balance of settings. You want a smooth finish, but not so smooth that it loses the detail of your print. Think about how easily you can see rat paw prints in the sand – how easily see rat paw prints look like – that’s the kind of detail you want to preserve on your print.

A little bit of texture is good, but too much can make your print look rough. Experiment with different settings and see what works best for you!

Troubleshooting Common Issues

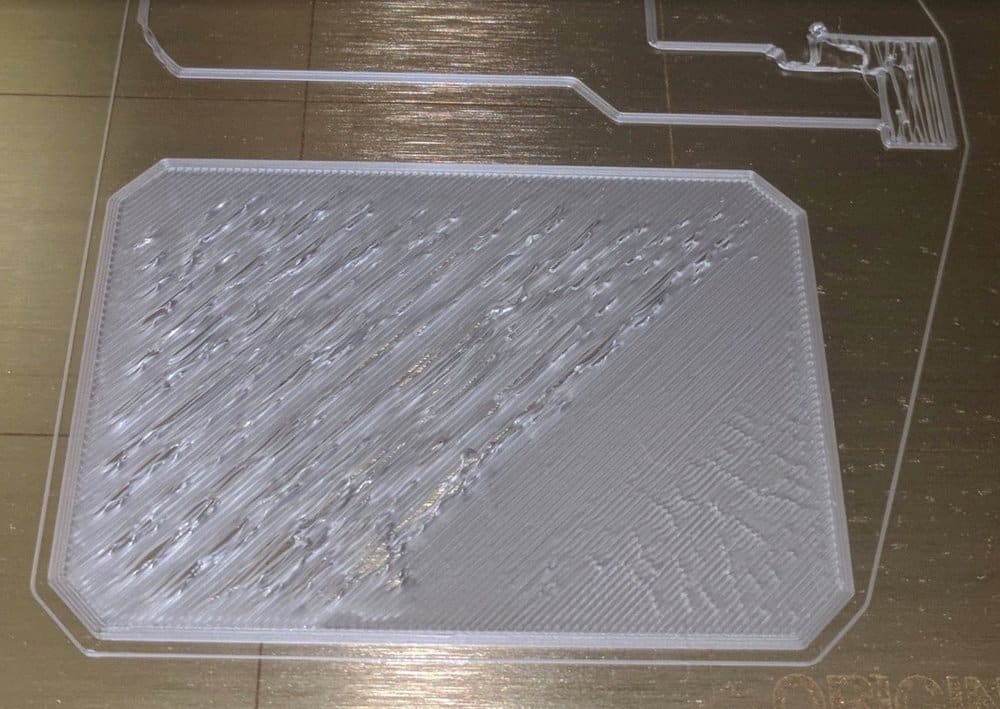

Even with careful preparation and printing techniques, you might encounter issues that affect the smoothness of your 3D prints. This section will cover some common problems and provide solutions to help you achieve those beautiful, polished surfaces.

Identifying Common Issues

Recognizing the source of surface imperfections is the first step towards fixing them. Common culprits include:

- Stringing:Thin strands of filament that extend from the print, often appearing as “spiderwebs” or “hairs.” This occurs when the filament cools too quickly before solidifying, leading to excess material being deposited.

- Layer Lines:Visible lines between layers, which can be more pronounced on smooth surfaces. These lines are formed when the print head moves up a layer and deposits new material, creating a slight step.

- Uneven Surfaces:Areas of the print with uneven texture or inconsistent smoothness. This can result from variations in filament flow, nozzle clogging, or inconsistencies in the print bed’s surface.

- Overextrusion:Too much filament being deposited, leading to raised areas or blobs on the print surface. This can occur due to incorrect flow rate settings or nozzle clogging.

- Underextrusion:Insufficient filament being deposited, resulting in gaps or thin areas on the print surface. This can be caused by insufficient filament flow, nozzle clogging, or incorrect extrusion settings.

Addressing Stringing

Stringing can be minimized by:

- Lowering the Retraction Speed:This allows the filament to cool more slowly before retracting, reducing the amount of stringing.

- Increasing the Retraction Distance:A longer retraction distance pulls more filament back into the nozzle, minimizing the amount of material left behind.

- Adjusting the Cooling Fan Speed:A higher fan speed can help cool the filament faster, reducing stringing.

- Using a Retraction Tower:This print object is designed to test retraction settings and identify the optimal configuration for your printer and filament.

Minimizing Layer Lines

While layer lines are an inherent part of 3D printing, you can reduce their visibility by:

- Using a Higher Print Resolution:A higher resolution means smaller layer heights, which results in less noticeable layer lines.

- Printing at a Slower Speed:Slower printing allows more time for each layer to cool and solidify before the next layer is deposited, minimizing the step between layers.

- Adjusting the Layer Height:Experiment with different layer heights to find the best balance between print time and layer line visibility.

- Using a Smooth Filament:Some filaments, such as PLA+, are designed for smoother surfaces and reduced layer line visibility.

Correcting Uneven Surfaces

Uneven surfaces can be addressed by:

- Calibrating the Extruder:Ensuring the extruder is properly calibrated ensures consistent filament flow, which is crucial for smooth surfaces.

- Cleaning the Nozzle:A clogged nozzle can cause inconsistent filament flow, leading to uneven surfaces.

- Leveling the Print Bed:A properly leveled print bed ensures that the first layer adheres correctly, preventing warping and uneven surfaces.

- Using a Smooth Build Plate:A smooth build plate surface can help reduce surface imperfections and improve overall print quality.

Essential FAQs

What are the best filaments for smooth 3D prints?

Filaments like PLA, PETG, and Nylon are generally known for their ability to produce smooth surfaces. However, the specific filament type and brand can significantly impact the final finish.

How do I prevent stringing on my 3D prints?

Stringing is caused by excess filament being deposited between layers. You can minimize stringing by adjusting your printer settings, such as reducing retraction speed and distance.

What is the best way to sand 3D prints?

Start with coarse-grit sandpaper and gradually work your way to finer grits to achieve a smooth finish. Use a sanding block for even pressure and to avoid introducing imperfections.

Can I use a heat gun to smooth 3D prints?

While a heat gun can be used to smooth certain types of plastic, it’s important to be cautious as excessive heat can warp or damage your print.