What causes stringing in 3D printing? It’s a common problem that can mar the aesthetics of your prints, leaving unsightly strands of filament trailing across your creation. This phenomenon occurs when molten plastic, still in a semi-liquid state, drips from the nozzle and solidifies mid-air, creating those unsightly stringers.

Stringing is often caused by a combination of factors, including the type of filament you’re using, your printer’s settings, and even the environment in which you’re printing. But don’t despair, there are solutions! By understanding the root causes of stringing and implementing a few adjustments, you can achieve smoother, more professional-looking prints.

Understanding Stringing

Stringing, also known as “bridging,” is a common issue in 3D printing that results in thin, unwanted strands of filament connecting different parts of your printed model. It happens when molten plastic continues to flow from the nozzle even after the print head has moved to a new position.

Stringing in 3D printing happens when melted plastic oozes out between layers, leaving unsightly strands. It’s a common issue, especially when printing at high speeds or with certain filament types. You might be thinking, “Wait, this is 3D printing, not regular printing, what’s the deal with dots per inch?” Well, it’s actually related to the resolution of your 3D printer, which affects how smooth the printed surface is.

You can find out more about the standard dots per inch for printed work on this website: what is the standard dots per inch for printed work. This knowledge can help you understand how printer resolution affects stringing, and how to adjust your print settings for a cleaner finish.

Appearance of Stringing

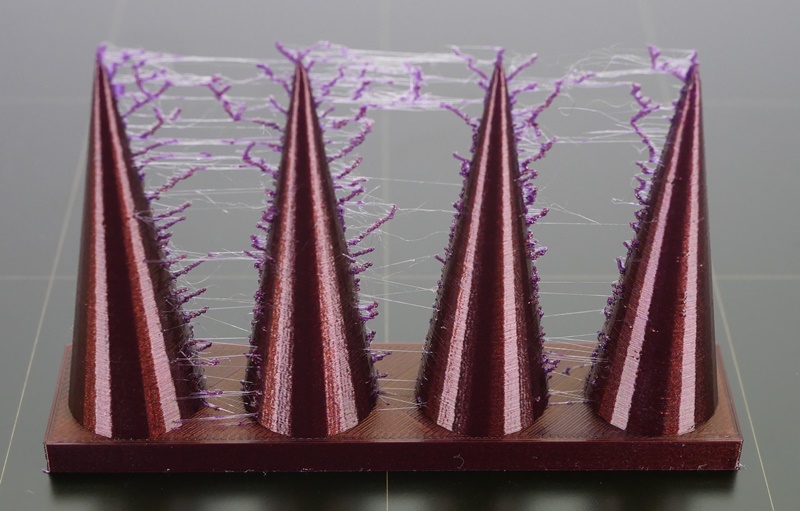

Stringing manifests as thin, often wispy filaments that bridge between different parts of the printed model, sometimes resembling spider webs. These strands are usually made of the same material as the model, but they are often weaker and more brittle.

Common Scenarios Where Stringing Occurs

Stringing is more likely to occur in certain situations.

- High printing temperatures:When the filament is heated to a higher temperature, it becomes more fluid and prone to stringing.

- Fast printing speeds:When the print head moves quickly, the filament may not have enough time to solidify before it starts to flow out of the nozzle, resulting in stringing.

- Sharp corners and overhangs:When the print head needs to make sharp turns or print overhangs, it can be more challenging to control the flow of filament, increasing the likelihood of stringing.

- Improper retraction settings:Retraction is the process of pulling the filament back into the nozzle after the print head moves. If the retraction settings are not optimized, the filament may not retract fully, leading to stringing.

Advanced Stringing Solutions

So far, we’ve discussed the fundamentals of stringing and basic solutions. But what if those aren’t enough? Let’s delve into more advanced techniques to conquer this common 3D printing problem.

Specialized Printing Techniques

Specialized printing techniques can significantly reduce stringing. One such technique is retraction, which involves pulling the filament back slightly when the extruder moves between points. This prevents molten plastic from being left behind, minimizing stringing. Another technique is coast, which involves slowing down the extruder speed before it completely stops.

This allows the filament to cool slightly, reducing the amount of molten plastic that can form strings.

Benefits and Drawbacks of Support Structures

Support structures are essential for overhangs and complex geometries, but they can also contribute to stringing. While support structures can provide a platform for the print to adhere to, they can also create more surface area for molten plastic to adhere to, leading to stringing.

The key is to use the right support structure settings and material.

Optimizing Printing Parameters for Stringing Reduction

Tweaking your printing parameters can make a big difference in stringing reduction.

- Lowering the print temperaturecan help reduce the amount of molten plastic that can be extruded.

- Increasing the retraction speedcan minimize the amount of time the filament is exposed to the hot nozzle, reducing stringing.

- Adjusting the retraction distancecan ensure that enough filament is retracted to prevent stringing.

- Using a higher print speedcan help minimize the time the filament is exposed to the hot nozzle, reducing stringing.

Post-Processing Techniques for Removing Stringing

Post-processing techniques can help remove stringing after the print is complete.

- Using a sharp blade or hobby knifecan be used to carefully remove stringing from the print.

- Sandingcan be used to smooth out the surface of the print and remove any remaining stringing.

- Acetone vapor smoothingcan be used to smooth out the surface of the print and remove stringing.

3D Printing Software Settings for Stringing Reduction, What causes stringing in 3d printing

Many 3D printing software programs have settings specifically designed to reduce stringing.

Retraction settings

These settings control how much filament is retracted and how quickly it is retracted.

Coast settings

These settings control how long the extruder coasts before it completely stops.

Temperature settings

These settings control the temperature of the hot end, which can affect the amount of stringing.

Print speed settings

These settings control the speed at which the print is extruded, which can affect the amount of stringing.

FAQ Explained: What Causes Stringing In 3d Printing

What is the best way to clean up stringing after a print?

You can use a sharp hobby knife or a pair of tweezers to carefully remove stringing from your prints. If the stringing is stubborn, you can try using a small amount of rubbing alcohol to soften it.

Can stringing affect the structural integrity of a print?

In most cases, stringing is purely an aesthetic issue. However, if stringing is particularly thick or extensive, it can potentially weaken a print’s structural integrity.

Is stringing more common with certain filament types?

Yes, some filament types are more prone to stringing than others. For example, flexible filaments like TPU often string more than rigid filaments like PLA.