What does collate mean for printing? In the world of printing, collation is the process of arranging pages in the correct order before they are bound or assembled into a final product. Imagine you’re building a house of cards; each card needs to be placed in the right spot to make the structure stand.

Collation is like that for printed documents – ensuring the pages are in the right sequence for a perfect final product.

Collation is essential for any printed material, from books and magazines to brochures and manuals. It ensures that the pages are in the correct order, so the reader can follow the flow of information without any confusion. Without proper collation, a printed document would be like a jigsaw puzzle with missing pieces, leaving the reader frustrated and confused.

Definition of Collation in Printing: What Does Collate Mean For Printing

Collation in printing refers to the process of arranging printed pages in the correct order before binding them into a book or booklet. It’s like assembling a puzzle, but instead of fitting shapes together, you’re arranging pages to create the intended sequence.

Collation in Printing: Analogy

Imagine you’re baking a cake and have all the ingredients in separate bowls. Collation in printing is like organizing the ingredients in the right order before mixing them to create the final cake. Each ingredient represents a page, and the order in which you combine them determines the final outcome of the cake, just as the order of pages in a book determines the flow of the story.

Collating for printing means organizing pages in the correct order, like a deck of cards. This ensures that your printed documents come out with all the pages in the right sequence. So, when you hear “collated print,” you’re basically asking for the printer to do this extra step for you.

Check out this article to learn more about what does collated print mean and how it works. Collation makes your printing experience smoother, especially for multi-page documents, by eliminating the need to manually organize the pages after printing.

Purpose of Collation in Printing

Collation is a crucial step in the printing process, ensuring that the pages of a printed document are arranged in the correct order. It is like assembling a puzzle, where each page is a piece that needs to be placed in its rightful position to create the complete picture.

Without proper collation, the final printed product would be a jumbled mess, rendering it useless.

Ensuring Page Order Accuracy

Collation plays a vital role in maintaining the accuracy of the printed document’s page order. It guarantees that pages are arranged sequentially, starting with the first page and ending with the last. This sequential arrangement is essential for the reader to follow the flow of information and understand the content presented.

Importance for Professional and Accurate Printing

Collation is not merely a cosmetic detail but a crucial aspect of producing a professional and accurate printed product. When pages are collated correctly, it reflects a high level of attention to detail and quality control. This meticulous approach enhances the credibility of the printed material and ensures that the intended message is conveyed effectively.

Collation Methods

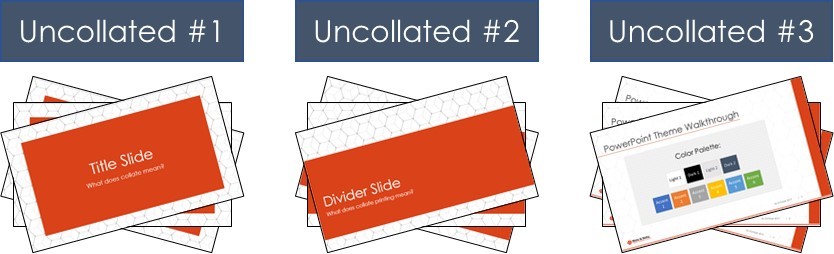

Collating printed materials is the process of arranging pages in the correct order before binding. There are several methods used for collation, each with its own advantages and disadvantages. These methods can be broadly categorized as manual collation and automated collation.

Manual Collation, What does collate mean for printing

Manual collation is the traditional method of collating printed materials. It involves manually arranging pages in the correct order, usually by hand. This method is simple and inexpensive, but it can be time-consuming and prone to errors.

- Stacking and Checking: This method involves stacking pages in the correct order, and then checking each stack against a master sheet or a checklist. This method is simple and inexpensive, but it can be time-consuming and prone to errors, especially for large print runs.

- Gathering: This method involves gathering pages from different stacks into a single unit. This method is more efficient than stacking and checking, but it can still be time-consuming and prone to errors.

Automated Collation

Automated collation is a more efficient and accurate method of collating printed materials. It involves using specialized machinery to collate pages automatically. This method is faster and more accurate than manual collation, but it can be more expensive.

- Sheet-fed Collators: These collators are used for collating sheets of paper that have been printed on a sheet-fed press. The sheets are fed into the collator in a specific order, and the collator arranges them into the correct sequence.

- Web Collators: These collators are used for collating pages that have been printed on a web press. The web of paper is fed into the collator, and the collator cuts the web into sheets and arranges them into the correct sequence.

Comparison of Manual and Automated Collation

| Method | Speed | Accuracy | Cost |

|---|---|---|---|

| Manual Collation | Slow | Low | Low |

| Automated Collation | Fast | High | High |

Collation in Different Printing Processes

Collation, the process of arranging printed pages in the correct order, is essential for creating a finished product that is readable and usable. The way collation is implemented can vary depending on the printing process. This section explores how collation is carried out in offset printing, digital printing, and large-format printing.

Collation in Offset Printing

Offset printing is a widely used process for high-volume printing, and it relies on a complex system of plates, rollers, and inks to transfer images onto paper. Collation in offset printing is typically handled by a specialized piece of equipment called a “collator.” Collators are designed to gather and stack printed sheets in the correct order, ensuring that the final product is assembled correctly.

Offset printing often involves multiple printing units, each responsible for printing a different color or section of the page. After each unit, the printed sheets are fed into the collator, where they are assembled in the correct sequence. Collators can be configured to handle a variety of paper sizes and thicknesses, and they can be used to collate documents with different page counts.

Collation in Digital Printing

Digital printing offers several advantages over offset printing, including faster turnaround times, lower setup costs, and the ability to print on demand. In digital printing, collation is typically handled by the printing device itself, which is often equipped with an integrated finishing system.The digital printing process typically involves printing multiple pages onto a single sheet of paper, which is then cut and folded to create the final document.

This process eliminates the need for a separate collator, simplifying the printing workflow.

Collation in Large-Format Printing

Large-format printing is used to create posters, banners, maps, and other oversized printed materials. Collation in large-format printing presents unique challenges due to the size and weight of the printed sheets. Large-format printing often involves printing on rolls of paper, which are then cut into individual sheets after printing.

Collation in this context typically involves stacking the printed sheets in the correct order, ensuring that they are aligned and ready for further processing. Due to the size and weight of the sheets, manual collation is often used, requiring careful handling to prevent damage.

In some cases, specialized equipment may be used to facilitate collation, such as a “sheet-fed collator” that can handle large sheets of paper. However, these machines are often expensive and may not be practical for smaller print shops.

Impact of Collation on Printing Efficiency

Collation, the process of arranging printed sheets in the correct order, plays a crucial role in printing efficiency. Efficient collation directly impacts the overall speed and accuracy of the printing process, ultimately influencing the cost and timeliness of the final product.

Time Required for Collation

The time needed for collation varies significantly depending on the chosen method. Here’s a comparison of the time required for different collation methods:

| Collation Method | Time Required | Advantages | Disadvantages |

|---|---|---|---|

| Manual Collation | High | Cost-effective for small print runs | Prone to errors, time-consuming |

| Off-line Collation | Moderate | Faster than manual collation, suitable for medium print runs | Requires additional equipment, less accurate than in-line collation |

| In-line Collation | Low | Fastest method, highly accurate, ideal for large print runs | Requires specialized equipment, expensive |

Factors Influencing Collation Speed and Accuracy

Several factors can influence the speed and accuracy of collation:

- Print Run Size:Large print runs generally require faster collation methods like in-line collation, while smaller runs can be efficiently handled with manual or off-line collation.

- Number of Pages:More pages in a document increase the complexity and time required for collation.

- Collation Method:Different collation methods have varying levels of speed and accuracy, as highlighted in the table above.

- Equipment:The efficiency of collation equipment significantly impacts the speed and accuracy of the process. Modern, automated collation systems can handle high volumes with minimal errors.

- Operator Skill:For manual collation, the skill and experience of the operator play a significant role in the accuracy and speed of the process.

Collation Errors and Their Consequences

Collation errors, though seemingly minor, can have significant repercussions in the printing process, leading to misaligned pages, incorrect page order, and ultimately, a compromised final product. It’s crucial to understand the potential consequences of such errors and implement strategies to minimize their occurrence.

Types of Collation Errors

Collation errors can arise from various sources, leading to different types of mistakes.

- Missing Pages:This is a common error where one or more pages are omitted from the final document, leading to incomplete sections or chapters.

- Duplicate Pages:Conversely, duplicate pages can also occur, resulting in an unnecessarily lengthy document and potentially confusing readers.

- Incorrect Page Order:This is a significant error where pages are arranged in the wrong sequence, disrupting the flow of the document and creating a confusing reading experience.

- Misaligned Pages:In some cases, pages might be misaligned within the document, leading to uneven margins and a visually unappealing presentation.

Consequences of Collation Errors

Collation errors can have a range of consequences, impacting the quality, efficiency, and cost of the printing process.

- Reduced Quality:Collation errors result in a substandard final product, affecting the overall presentation and professionalism of the document.

- Increased Costs:Rectifying collation errors often involves reprinting and re-collating, leading to additional expenses and delays in production.

- Damaged Reputation:Errors in printed materials can reflect negatively on the organization or individual responsible for the publication, potentially damaging their reputation.

- Customer Dissatisfaction:Receiving a document with collation errors can lead to customer dissatisfaction, resulting in negative feedback and potential loss of business.

Preventing Collation Errors

Preventing collation errors requires a multi-faceted approach, involving careful planning, meticulous execution, and effective quality control measures.

- Clear and Accurate Page Numbering:Ensuring accurate and consistent page numbering is crucial for correct collation. Using a numbering system that is easy to follow and visually distinct helps avoid errors.

- Double-Checking Page Order:It is essential to thoroughly review the page order before and after collation, verifying that pages are arranged correctly and sequentially.

- Utilizing Collation Software:Specialized collation software can automate the collation process, minimizing the risk of human error and ensuring accuracy.

- Implementing Quality Control Measures:Implementing a robust quality control system, involving multiple checks at different stages of the printing process, helps identify and rectify collation errors before final printing.

Collation in Different Industries

Collation isn’t just a printing process; it’s a vital aspect of various industries, ensuring the correct order and arrangement of printed materials. This meticulous process guarantees the intended flow of information and enhances the overall quality of the final product.

Collation in Publishing

Collation plays a crucial role in the publishing industry, particularly for books, magazines, and journals. The accurate sequencing of pages is essential for a seamless reading experience.

“Collation in book publishing ensures that the pages are arranged in the correct order, preventing readers from encountering a jumbled mess of text and images.”

For instance, in a book, collation ensures that chapters, sections, and pages appear in the intended order. Incorrect collation can lead to confusion and frustration for readers.

Collation in Marketing

In the marketing realm, collation is vital for creating impactful marketing materials, such as brochures, flyers, and catalogs. The accurate arrangement of pages ensures that the intended message is delivered effectively.

“Collation in marketing materials guarantees that the marketing message is presented in the correct order, maximizing its impact and effectiveness.”

For example, a brochure promoting a new product might have different sections showcasing features, benefits, and testimonials. Accurate collation ensures that these sections appear in the intended sequence, creating a compelling narrative.

Collation in Education

Collation is also essential in the education sector, especially for textbooks, manuals, and workbooks. Accurate collation guarantees that students receive the information in the correct order, facilitating their learning process.

“Collation in educational materials ensures that students receive the information in the correct order, promoting effective learning and understanding.”

For instance, a math textbook might have chapters covering different topics, each with exercises and examples. Collation ensures that these chapters and their associated content are presented in the intended sequence, allowing students to progress through the material systematically.

Collation Requirements for Different Printed Products

| Printed Product | Collation Requirements ||—|—|| Books | Complex, involving multiple signatures, sections, and pages || Brochures | Simple, often requiring two or four pages to be collated || Manuals | Varies depending on the complexity of the manual, often involving multiple sections || Flyers | Usually simple, requiring only two pages to be collated || Magazines | Similar to books, with multiple signatures and sections || Journals | Often require complex collation due to multiple articles and sections |

Quick FAQs

What happens if pages are not collated correctly?

If pages are not collated correctly, the printed document will be out of order, making it difficult or impossible to read. This can lead to confusion and frustration for the reader, and may even damage the reputation of the publisher or printer.

How do I know if a document has been collated correctly?

You can check if a document has been collated correctly by flipping through the pages and making sure that they are in the correct sequence. You can also look for any obvious misalignments or missing pages.

Is collation necessary for all types of printed materials?

Yes, collation is necessary for any printed material that has multiple pages, such as books, magazines, brochures, and manuals. It is essential for ensuring that the pages are in the correct order, so the reader can follow the flow of information without any confusion.