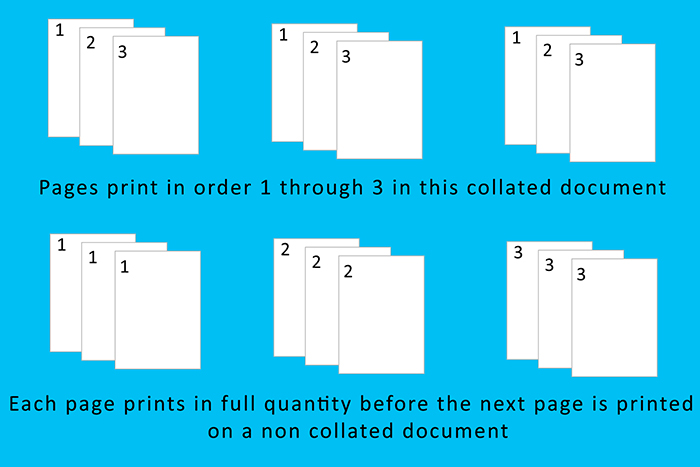

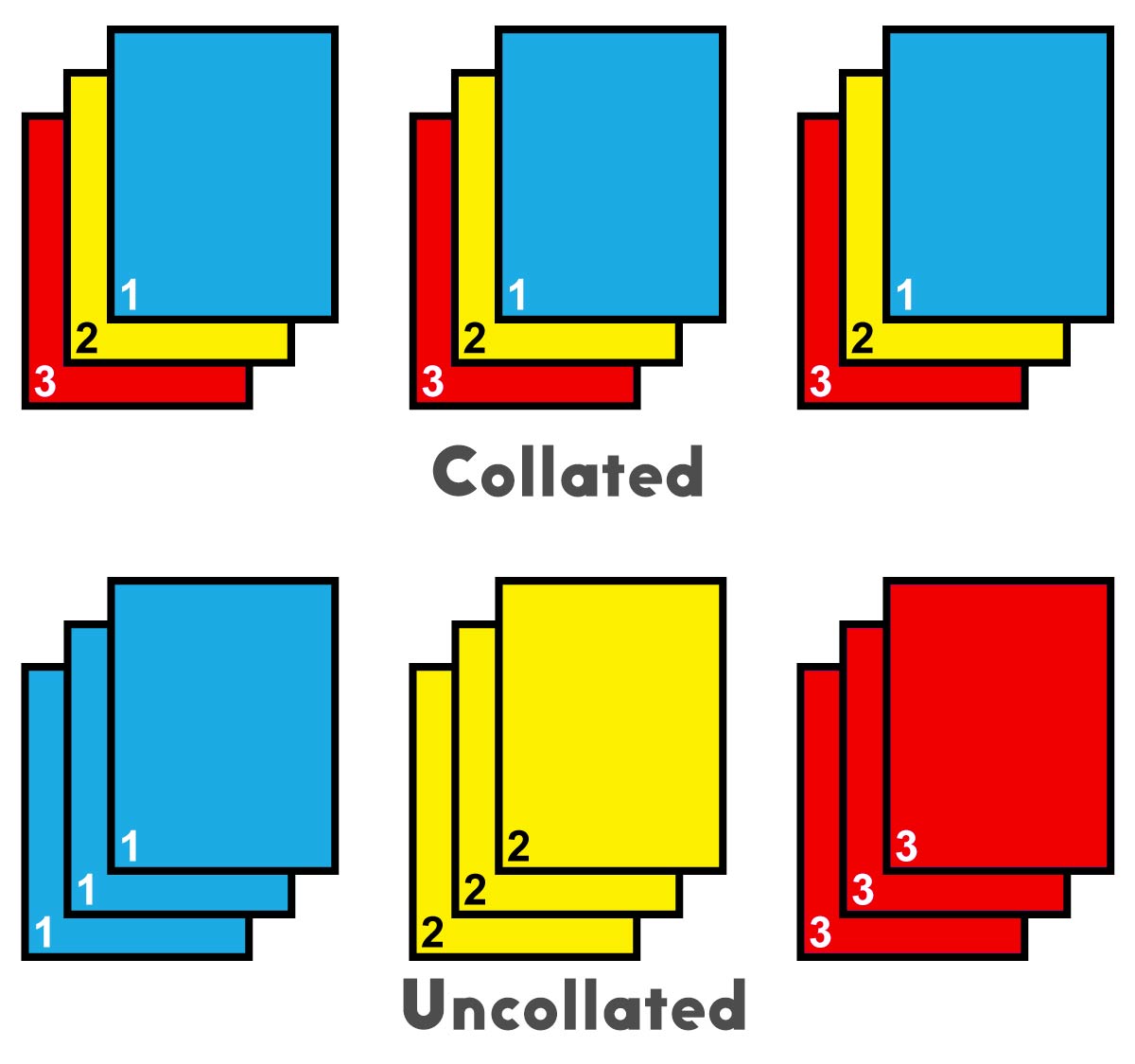

What does collate mean on printing sets the stage for this exploration, offering readers a glimpse into the world of print production. Collation, in essence, is the process of arranging printed sheets in the correct order before binding. This seemingly simple task is crucial for ensuring a professional and cohesive final product.

Imagine receiving a book where the pages were out of order – frustrating, right? Collation prevents this chaos and ensures that your printed materials are presented in the intended sequence, making them easy to read and navigate.

Collation plays a vital role in a variety of printing projects, from simple brochures and flyers to complex books and magazines. Understanding the different methods, techniques, and potential challenges associated with collation can help you produce high-quality printed materials that meet your specific needs.

Whether you’re a seasoned printer or a curious individual interested in the intricacies of print production, this guide will provide you with a comprehensive understanding of collation in printing.

Understanding Collation in Printing

Collation is a crucial step in the printing process, especially when dealing with multi-page documents. It involves arranging printed sheets in the correct order to create a complete and accurate final product. Imagine printing a book – each page needs to be in the right sequence, ensuring a smooth reading experience.

The Purpose of Collation in Printing

Collation aims to ensure the correct sequence of printed pages in a document. This is essential for maintaining the integrity of the document and delivering a professional-looking final product. Without proper collation, printed materials might have pages out of order, leading to confusion and frustration for the reader.

Benefits of Collation in Printing

Collation offers several advantages:

- Accurate and Professional Final Product:Collation ensures the pages are arranged in the right order, delivering a professional-looking and accurate final product. This is crucial for documents like books, brochures, and reports where a logical sequence is essential.

- Reduced Errors:By systematically organizing pages, collation minimizes the risk of errors like missing pages or pages out of order, ensuring a flawless final product.

- Improved Efficiency:Collation streamlines the printing process by ensuring that pages are ready for binding or finishing in the correct order. This reduces the time and effort required for manual sorting and re-arranging.

Examples of Collation in Printing

Collation is vital for a variety of printing projects, including:

- Books:Collation is essential for assembling the pages of a book in the correct order, ensuring a smooth reading experience for the reader.

- Brochures:Brochures often contain multiple panels that need to be folded and assembled correctly. Collation ensures that the panels are arranged in the right order for a professional-looking final product.

- Magazines:Similar to books, magazines require collation to arrange pages in the correct order, ensuring a seamless reading experience.

- Reports:Reports often contain multiple sections that need to be assembled in a specific order. Collation ensures that the sections are arranged correctly, providing a clear and logical flow of information.

Collation Methods: What Does Collate Mean On Printing

Collating printed materials refers to the process of arranging pages in the correct order before binding or finishing. This is a crucial step in ensuring the final product is accurate and presentable. There are different methods used for collating, each with its own advantages and disadvantages.

Manual Collation

Manual collation involves physically arranging pages by hand. This method is often used for small print runs or when the complexity of the document doesn’t warrant automation.

Process

- The first step in manual collation is to gather all the printed pages and separate them into individual stacks based on their page number.

- Next, the stacks are arranged in numerical order, ensuring that the pages are aligned correctly.

- The collator then picks up one page from each stack and places them in the correct sequence, forming a complete set.

- This process is repeated until all the sets are complete.

Automated Collation

Automated collation utilizes specialized equipment to arrange pages in the correct order. This method is ideal for large print runs, complex documents, and when speed and accuracy are paramount.

Process

- Automated collation systems typically use a series of feeders and conveyors to move pages through the machine.

- The pages are fed into the machine in their respective stacks, and sensors detect the page numbers.

- The machine then arranges the pages in the correct order, often using a series of trays or bins to hold the completed sets.

- Automated collators can be programmed to handle different page sizes, orientations, and quantities, making them highly versatile.

Advantages and Disadvantages

| Method | Advantages | Disadvantages |

|---|---|---|

| Manual Collation |

|

|

| Automated Collation |

|

|

Collation Order and Sequence

Getting the collation order right is crucial for ensuring that your printed materials are assembled correctly. It’s like putting together a puzzle – each piece needs to be in the right place for the final product to be complete and accurate.

Determining the Correct Collation Sequence

Determining the correct collation sequence depends on the type of printed material and the desired outcome. Here’s how you can figure it out:

- Examine the layout:Look at the design of your printed piece. How many pages are there? Are there any specific sections or inserts? This will give you a good idea of the order in which the pages need to be assembled.

- Consider the intended use:Is it a brochure, a magazine, a book, or something else? The intended use will influence the collation order. For example, a brochure might be folded in a specific way, requiring a different collation sequence than a magazine.

- Consult a professional printer:If you’re unsure about the correct collation order, don’t hesitate to consult with a professional printer. They have experience with various printing projects and can provide expert advice.

Common Collation Sequences

Here are some common collation sequences used in different printing applications:

- Single-sheet documents:These are often printed in a single pass, so there’s no need for specific collation. However, if there are multiple copies, they might be stacked together in the correct order.

- Brochures:Brochures typically have a sequence of pages that are folded and then stapled or glued together. The most common collation order for a 4-page brochure is 1-4, 2-3, with the first page on top.

- Magazines:Magazines have a more complex collation order, depending on the number of pages and whether they have inserts or covers. A common sequence for a 32-page magazine might be 1-32, 2-31, 3-30, 4-29, 5-28, 6-27, 7-26, 8-25, 9-24, 10-23, 11-22, 12-21, 13-20, 14-19, 15-16, 17-18, with the cover pages being the last to be added.

- Books:Books require a precise collation order, with the pages arranged in the correct sequence for the entire volume. This is often done by professional binders, who use specialized equipment to ensure accurate collation.

Examples of Collation Orders

| Type of Printed Material | Collation Order ||—|—|| 4-page Brochure | 1-4, 2-3 || 8-page Booklet | 1-8, 2-7, 3-6, 4-5 || 16-page Magazine | 1-16, 2-15, 3-14, 4-13, 5-12, 6-11, 7-10, 8-9 || 32-page Book | 1-32, 2-31, 3-30, 4-29, 5-28, 6-27, 7-26, 8-25, 9-24, 10-23, 11-22, 12-21, 13-20, 14-19, 15-16, 17-18 |

Collation Errors and Troubleshooting

Collation errors can happen during the printing process, resulting in a misordered sequence of pages in your final printed product. It’s essential to understand common errors and how to troubleshoot them to ensure accurate and professional-looking printed materials.

Common Collation Errors

Collation errors can occur at different stages of the printing process. Some of the most common errors include:

- Missing Pages:This is one of the most common errors, where a page or pages are entirely absent from the final product.

- Duplicate Pages:The same page appears twice in the sequence, leading to a page count mismatch.

- Out-of-Order Pages:Pages are printed in the wrong sequence, resulting in a scrambled document.

- Incorrect Signatures:Signatures are groups of pages that are folded and stitched together. If signatures are misaligned, the entire document can be out of order.

Troubleshooting Collation Errors

Here’s a step-by-step approach to troubleshooting collation errors:

- Identify the Error:Carefully examine the printed product to determine the specific type of error. For example, are pages missing, duplicated, or out of order?

- Check the Collation Sequence:Verify the intended page order against the actual printed sequence. This can be done by comparing the printed document to the original file or a printed proof.

- Review the Collation Process:If the error is consistent throughout the entire print run, it’s likely a problem with the collation process itself. Examine the collation machine for any misalignments or malfunctions.

- Inspect the Signatures:If the error involves signatures, check if they are correctly assembled and stitched together. Misaligned or incorrectly stitched signatures can lead to out-of-order pages.

- Re-Collate and Re-Print:If the error is identified and corrected, the affected pages or signatures need to be re-collated and re-printed.

Impact of Collation Errors

Collation errors can have a significant impact on the final printed product, including:

- Professionalism:A document with collation errors can appear unprofessional and poorly produced.

- Clarity and Readability:Out-of-order pages can make it difficult for readers to follow the content and understand the information presented.

- Brand Reputation:Collation errors can damage the brand reputation of a company or organization.

- Cost and Time:Correcting collation errors can be time-consuming and costly, especially if a large print run is involved.

Troubleshooting Flowchart

Collating in printing is like putting pages in order, so you get a nice, organized document. But what if your document is a GIF? You might wonder what does a gif photo print look like , right? Well, it’s like printing a series of still images from the GIF, so you get a little story on paper.

But collating still applies, you’d want the frames in the right order to make sense!

| Start | |

| Identify the Collation Error | Missing pages, duplicate pages, out-of-order pages, incorrect signatures |

| Check the Collation Sequence | Compare printed document to original file or proof |

| Review the Collation Process | Examine collation machine for misalignments or malfunctions |

| Inspect the Signatures | Check if signatures are correctly assembled and stitched together |

| Re-Collate and Re-Print | |

| End | |

Collation in Digital Printing

Collation is an essential aspect of printing, ensuring that printed pages are arranged in the correct order for binding or assembly. In digital printing, collation takes on a different form compared to traditional offset printing, leveraging technology to streamline the process and achieve accurate results.

Digital Collation Methods

Digital printing technologies often eliminate the need for manual collation, automating the process through software and specialized equipment. Digital printing machines typically use a technique called “in-line collation,” where pages are printed and collated simultaneously. This method involves using a series of feeders and stackers that align and arrange pages in the correct sequence as they are printed.

Comparison with Offset Printing

Traditional offset printing relies heavily on manual collation, where printed sheets are stacked and sorted by hand. This method is labor-intensive and prone to errors, particularly for large print runs. Digital printing, on the other hand, automates the collation process, reducing the risk of errors and improving efficiency.

Software Tools for Digital Collation

Digital printing workflows often utilize specialized software tools to manage collation. These tools provide features for creating and managing print jobs, including specifying collation sequences and verifying the accuracy of the final output. Some commonly used software tools for digital collation include:

- Prepress Software:Prepress software, such as Adobe InDesign and QuarkXPress, allow users to define page order and create imposition layouts for digital printing. These layouts determine the sequence in which pages are printed and collated.

- Digital Printing Workflow Software:Digital printing workflow software, such as EFI Fiery Command WorkStation and Kodak Prinergy, provide comprehensive tools for managing print jobs, including collation settings and output verification.

- RIP Software:Raster Image Processors (RIPs) translate vector-based images into raster images that can be printed by digital presses. Some RIP software includes features for managing collation and ensuring accurate output.

Collation and Binding

Collation and binding are two essential processes in the printing industry that work together to create a finished, organized, and durable printed product. Collation refers to the process of arranging printed sheets in the correct order, while binding refers to the method used to physically attach the pages together.

The Relationship Between Collation and Binding

Collation ensures that the printed pages are arranged in the correct sequence before they are bound. This is crucial for maintaining the intended reading order and creating a coherent document. The binding method chosen directly impacts the collation process. For instance, a book with a spine that requires pages to be folded in a specific way will necessitate a different collation sequence than a document that will be stapled or glued together.

How Collation Prepares Printed Materials for Binding

Collation is a vital step in preparing printed materials for binding. It ensures that the pages are in the correct order, allowing the binder to create a cohesive and readable document. The collation process involves carefully arranging individual printed sheets or signatures (groups of sheets folded together) into the correct sequence.

This process is typically done manually or using automated collation machines.

Different Binding Methods and Their Impact on the Collation Process

Various binding methods are available, each requiring specific collation procedures.

Different Binding Methods

- Perfect Binding: This method involves gluing the edges of the pages together to create a smooth spine. Perfect binding is commonly used for books, magazines, and brochures. Collation for perfect binding typically involves arranging signatures in the correct order, ensuring that the spine edge is aligned for efficient gluing.

- Saddle Stitch Binding: This method involves folding pages in half and stapling them through the fold line. Saddle stitching is often used for brochures, pamphlets, and magazines with a low page count. The collation process for saddle stitching involves arranging the pages in the correct order, ensuring that they are folded correctly before stapling.

- Spiral Binding: Also known as coil binding, this method involves punching holes down the spine of the document and inserting a plastic or metal coil. Spiral binding is commonly used for reports, notebooks, and presentations. The collation process for spiral binding involves arranging the pages in the correct order and punching holes in the spine for the coil.

- Wire-O Binding: This method involves punching holes down the spine of the document and inserting a double-loop wire. Wire-O binding is commonly used for calendars, notebooks, and journals. The collation process for Wire-O binding involves arranging the pages in the correct order and punching holes in the spine for the wire.

Examples of Collation and Binding in Specific Printing Projects, What does collate mean on printing

- Book Printing: For a book with a large page count, collation would involve arranging signatures in the correct order and then stitching them together to form sections. These sections are then glued together to create the book’s spine, a process known as perfect binding.

- Magazine Printing: Magazines often use saddle stitching, where the pages are folded in half and stapled together. The collation process would involve arranging the pages in the correct order, ensuring that they are folded correctly before stapling.

- Brochure Printing: Brochures can be bound using various methods, including saddle stitching, perfect binding, and spiral binding. The collation process would depend on the chosen binding method. For example, a saddle-stitched brochure would require the pages to be arranged in the correct order and folded before stapling.

User Queries

What are the most common collation errors?

Common collation errors include missing pages, duplicate pages, pages in the wrong order, and pages that are upside down or rotated.

How can I avoid collation errors?

To avoid collation errors, carefully check the order of the pages before binding, use a collation machine, and have a quality control process in place.

What is the difference between collation and binding?

Collation is the process of arranging pages in the correct order, while binding is the process of attaching the pages together to create a finished product.