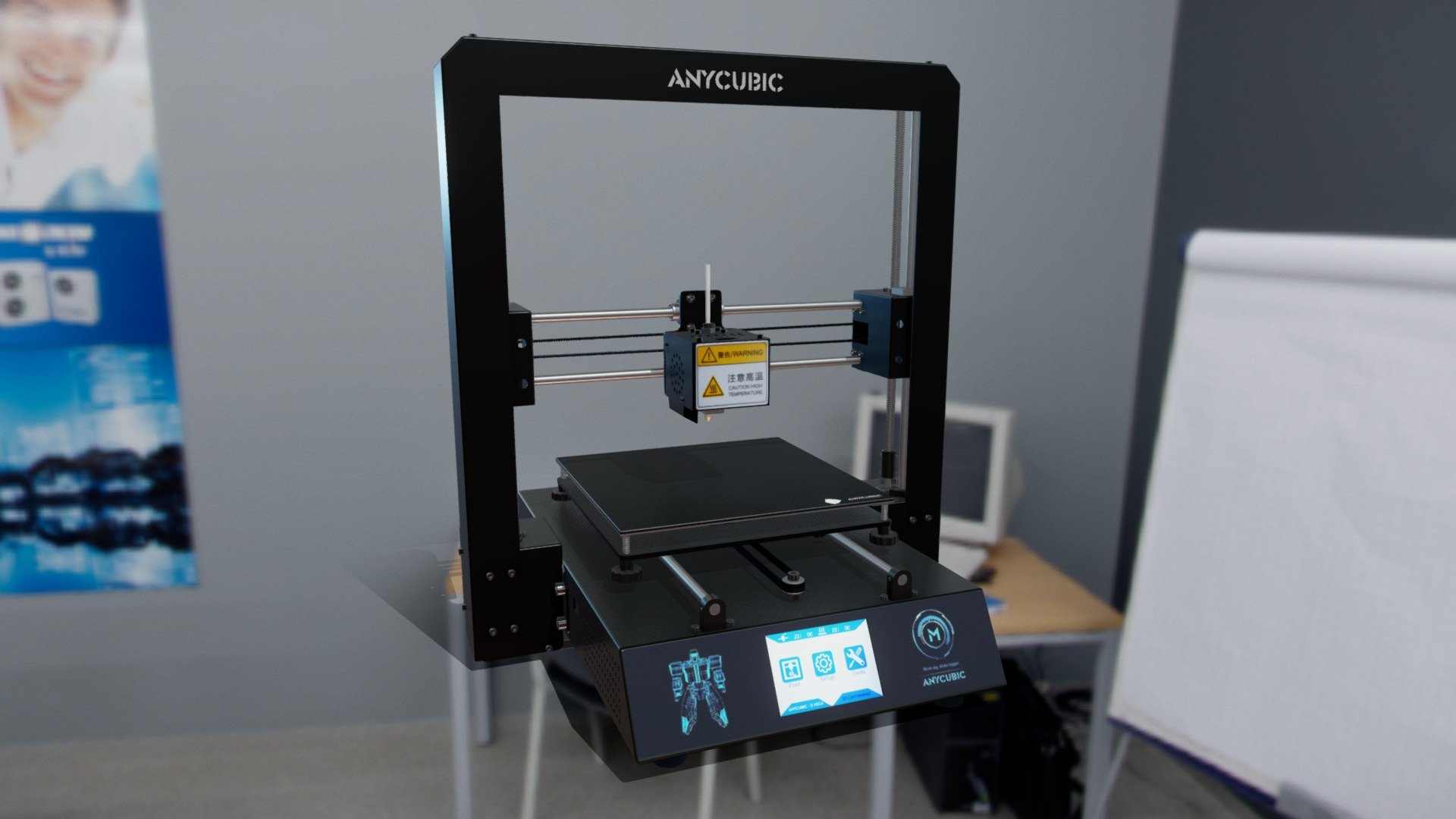

What file does the Anycubic i3 take to print? This question is essential for anyone stepping into the world of 3D printing with this popular machine. The Anycubic i3, like most 3D printers, relies on specific file formats to translate your digital designs into tangible objects.

Understanding these formats is crucial for getting your prints started and achieving the results you desire.

The primary file format used by the Anycubic i3 is the STL (Stereolithography) file. This format is a standard in the 3D printing world, representing a 3D model as a collection of triangular facets. The STL file contains information about the shape and size of the object, but it doesn’t include any details about the printing process itself.

Understanding File Types for 3D Printing

The Anycubic i3, like most 3D printers, works with specific file formats designed to represent three-dimensional models. These formats contain instructions for the printer to follow, dictating how to build your object layer by layer. Understanding these formats is crucial for preparing your designs for printing.

Common File Formats in 3D Printing

These are the most common file formats encountered in 3D printing:

- STL (Stereolithography): This is a widely used format that focuses on the surface geometry of a 3D model. It defines the model as a collection of triangular facets, effectively creating a mesh. STL files are simple and lightweight, making them suitable for sharing and basic 3D printing.

However, they lack information about colors, textures, or other details.

- OBJ (Wavefront OBJ): A more versatile format than STL, OBJ files can store not only geometry but also vertex normals, material properties, and even texture coordinates. This allows for more complex models and enables the representation of colors and surface details.

- AMF (Additive Manufacturing File Format): This format, developed by the ASTM International, aims to standardize 3D printing data. It offers a more comprehensive representation of 3D models, including detailed information about materials, colors, and even support structures. AMF files are becoming increasingly popular for their accuracy and flexibility.

- 3MF (3D Manufacturing Format): Introduced by Microsoft, 3MF aims to simplify 3D printing workflows. It combines the benefits of STL and OBJ while addressing their limitations. 3MF files can store multiple objects, materials, and even color information, making them ideal for complex designs.

File Format for Anycubic i3

The Anycubic i3 primarily accepts files in the STL format. This format is commonly used for 3D printing due to its simplicity and widespread compatibility with various 3D printing software and slicing programs.

Understanding STL File Structure

STL files are based on a simple text-based format that defines the surface of a 3D model as a collection of triangular facets. Each facet is represented by three vertices, which are points in 3D space. The STL file format also includes information about the normal vector of each facet, which helps determine the orientation of the triangle in space.

The STL file structure is relatively simple and straightforward. It consists of a header section followed by a list of facets. Each facet is defined by its three vertices and its normal vector.

STL files are often used for their simplicity and ease of use, but they lack the detailed information present in other formats like OBJ or 3MF. For basic 3D printing, the STL format is usually sufficient, but for more complex designs or applications requiring detailed material properties or color information, other formats may be preferred.

Preparing Files for the Anycubic i3

You’ve designed your 3D model, but before you can print it on your Anycubic i3, you need to prepare it. This involves slicing the model into layers, a process that creates the instructions your printer needs to build your creation.

Slicing the 3D Model

Slicing is the process of converting your 3D model into a format that your 3D printer can understand. This is done by a program called a slicer. There are many slicer programs available, but some popular options include:

- Cura

- PrusaSlicer

- Simplify3D

Each slicer has its own unique set of features and settings. However, the basic process of slicing a 3D model is similar across all slicers. Here’s a step-by-step guide to slicing a 3D model using Cura:

- Import your 3D model:Open Cura and click on “Open” to import your 3D model file. Supported file formats include STL, OBJ, and AMF.

- Select your printer:In Cura’s settings, choose your printer model. This ensures that the slicer generates instructions that are compatible with your Anycubic i3.

- Adjust slicing settings:This is where you can fine-tune the printing process. Some key settings to consider include:

- Layer height:This determines the thickness of each layer. Lower layer heights produce smoother prints, but take longer to print.

- Infill density:This controls the amount of material used to fill the inside of your print. Higher infill densities create stronger prints, but use more filament.

- Print speed:This controls the speed at which the printer extrudes filament. Faster speeds reduce print time, but may compromise print quality.

- Support structures:This setting adds support structures to your print, which are necessary for overhangs and complex geometries.

- Preview your print:Cura will generate a preview of your print, showing the sliced layers and the estimated print time. You can use this preview to make any final adjustments to your slicing settings.

- Save your sliced file:Once you’re happy with the slicing settings, save the sliced file. This file is typically in the G-code format, which your Anycubic i3 can understand.

Optimizing the Sliced File

Once you have your sliced file, you can further optimize it for optimal printing results. Here are some tips:

- Use a good quality filament:Filament quality can significantly affect the quality of your prints. Choose a reputable brand and ensure the filament is stored properly.

- Calibrate your printer:Ensure that your printer is properly calibrated. This includes adjusting the bed leveling, extruder calibration, and other settings.

- Use a heated bed:A heated bed helps to prevent warping and adhesion issues, especially with certain types of filament.

- Experiment with printing settings:Different models and filament types may require different printing settings. Experiment with various settings to find the optimal combination for your print.

Transferring Files to the Anycubic i3

You’ve designed your 3D model, sliced it into printable layers, and now you’re ready to bring your creation to life. The next step is transferring your 3D print file to the Anycubic i3. This guide will walk you through the common methods for loading your files onto the printer.

Connecting the Anycubic i3 to a Computer

Connecting your Anycubic i3 to your computer allows you to directly transfer files, manage settings, and even monitor the printing process. Here’s how you can establish this connection:* USB Cable:The Anycubic i3 usually comes with a USB cable that connects to a port on the printer.

This method is convenient for quick file transfers and allows you to access the printer’s control panel through the computer.

Software

Some 3D printing software, like Cura, includes a built-in function for connecting to your printer via USB. This provides an interface for uploading files, adjusting print settings, and monitoring the printing progress.

Your Anycubic i3 printer needs a file called an STL to print. It’s a 3D model file that tells the printer how to build your design layer by layer. You can find tons of cool STL files online, like this one for a a cold wall mens brutalist print cotton design, which would look super rad printed in a contrasting color.

Once you’ve got your STL, you can load it into your printer’s software and get printing!

Network Connection

Certain models of the Anycubic i3 support Wi-Fi or Ethernet connectivity. This allows you to connect the printer to your local network and transfer files from your computer without needing a direct USB connection.

Using an SD Card

An SD card is a convenient way to load files onto the Anycubic i

3. Here’s how to use this method

* Formatting the SD Card:The SD card needs to be formatted with the correct file system. Most 3D printers, including the Anycubic i3, require the SD card to be formatted as FAT32. You can use your computer’s file explorer to format the card.

Transferring Files

After formatting the SD card, copy the 3D print file (usually in .gcode format) to the card.

Inserting the SD Card

Locate the SD card slot on your Anycubic i3. Insert the card and ensure it’s securely in place.

Selecting the File

On the printer’s control panel, navigate to the SD card menu and select the file you want to print.

File Management on the Anycubic i3: What File Does The Anycubic I3 Take To Print

The Anycubic i3 utilizes an SD card for storing and accessing 3D printing files. Understanding the file structure and navigating the printer’s display is crucial for managing your print projects.

File Structure on the SD Card

The SD card on the Anycubic i3 typically has a simple file structure. Here’s a breakdown:

| Folder | Purpose |

|---|---|

| / | Root directory of the SD card. |

| /gcode | Contains G-code files for printing. |

| /model | Contains STL or other 3D model files. |

| /config | Contains printer configuration files. |

| /other | A general folder for other files. |

Navigating the File System on the Printer’s Display

The Anycubic i3’s display has a simple menu system for navigating files on the SD card. * Use the navigation buttons to move between folders and files.

- Select files to view their details or initiate printing.

- The “Back” button returns to the previous directory.

Deleting, Renaming, and Moving Files

The Anycubic i3’s display allows basic file management actions. * To delete a file, select it and press the “Delete” button.

- To rename a file, select it and press the “Rename” button. Enter the new name using the navigation buttons.

- To move a file, select it and press the “Move” button. Choose the destination folder using the navigation buttons.

Troubleshooting File Issues

File-related issues can be a frustrating hurdle in the 3D printing journey. Luckily, most problems are easily solved with a little troubleshooting. This section will guide you through identifying and fixing common file-related errors.

File Format Incompatibility, What file does the anycubic i3 take to print

The Anycubic i3 typically accepts files in STL and OBJ formats. If you try to print a file in an unsupported format, the printer won’t recognize it.Here’s how to resolve format incompatibility:

- Convert the file:Use a 3D modeling software or an online converter to change the file format to STL or OBJ. Popular online converters include:

- Online 3D Converter: [Link to a reliable online 3D converter]

- Convertify: [Link to a reliable online 3D converter]

- Check the printer’s manual:Refer to the Anycubic i3’s manual for a list of supported file formats. Some printers might accept additional formats.

Slicing Errors

Slicing errors occur when the slicing software fails to properly prepare the 3D model for printing. This can lead to errors like:

- Incorrect layer height:The slicer may struggle to create layers if the model’s details are too small or the layer height is set too low.

- Overlapping geometry:The slicer might encounter issues if the model contains overlapping surfaces.

- Insufficient support:Models with overhangs or complex geometries might require support structures that the slicer hasn’t generated correctly.

To troubleshoot slicing errors:

- Review the slicer settings:Ensure the layer height, infill percentage, and support settings are appropriate for your model and printer.

- Simplify the model:If possible, try simplifying the model by removing unnecessary details or reducing the level of detail.

- Use a different slicer:If you continue to encounter errors, try using a different slicing software. Popular options include:

- Cura: [Link to Cura download page]

- PrusaSlicer: [Link to PrusaSlicer download page]

Corrupted Files

Corrupted files can cause unexpected behavior during printing, leading to errors or incomplete prints.Here’s how to identify and fix corrupted files:

- Try opening the file in a different program:If the file opens without errors in another software, the problem might be with the original program.

- Download the file again:If you downloaded the file, try downloading it again to ensure it wasn’t corrupted during the download process.

- Use a file repair tool:Several online tools can help repair corrupted files. Search for “file repair tool” online to find suitable options.

Seeking Help

If you’re still facing file-related issues, there are several resources available for help:

- Online forums:Search for forums dedicated to 3D printing, such as [Link to a relevant forum]. You can post your issue and get assistance from experienced users.

- Manufacturer support:Contact Anycubic’s customer support for guidance on file-related issues.

- 3D printing communities:Join online communities like [Link to a relevant 3D printing community] to connect with other enthusiasts and seek advice.

Detailed FAQs

What are some popular slicing software options for the Anycubic i3?

Popular slicing software options for the Anycubic i3 include Cura, PrusaSlicer, and Simplify3D. These programs allow you to prepare your STL files for printing, setting parameters like layer height, infill density, and support structures.

How do I troubleshoot a file format incompatibility error on the Anycubic i3?

If you encounter a file format incompatibility error, ensure you’re using an STL file. If you have a different file type, you’ll need to convert it to STL using a 3D modeling software or online converter. Double-check that the file is not corrupted or damaged.

Can I use a USB drive to transfer files to the Anycubic i3?

Yes, you can use a USB drive to transfer files to the Anycubic i3. Many models have a USB port for this purpose. Simply format the USB drive to FAT32 and copy the STL file to the root directory of the drive.