What is 200×200 3d printer – What is a 200×200 3D printer? This term refers to a specific type of 3D printer with a build volume of 200mm x 200mm, offering a sizable workspace for creating various objects. These printers are popular among hobbyists and professionals alike due to their versatility and affordability.

They can be used to create a wide range of projects, from functional prototypes to intricate sculptures.

The 200×200 build volume provides ample space for creating larger objects, allowing you to bring your designs to life with greater detail and complexity. Whether you’re a beginner or an experienced maker, understanding the features and capabilities of 200×200 3D printers is essential for choosing the right model for your needs.

Introduction to 200×200 3D Printers

A 200×200 3D printer refers to a machine with a build volume of 200 millimeters (mm) by 200 mm, providing a square printing area. This build volume is a popular choice for many hobbyists and professionals due to its versatility and ability to accommodate a wide range of projects.The significance of the 200×200 build volume lies in its ability to produce larger and more complex models compared to smaller printers.

This size allows for the creation of detailed prototypes, functional parts, and even artistic creations.

Applications and Benefits of 200×200 3D Printers

The applications of 200×200 3D printers are vast and diverse, spanning across various industries and personal endeavors. Here are some of the key benefits and applications:

- Prototyping:200×200 3D printers are ideal for creating prototypes of products, tools, and designs. This build volume allows for the creation of larger and more detailed prototypes, enabling designers and engineers to test and refine their ideas before committing to expensive production methods.

- Functional Parts:These printers can produce functional parts for various applications, including mechanical components, custom tools, and even replacement parts for everyday objects. The larger build volume allows for the creation of more complex and robust parts.

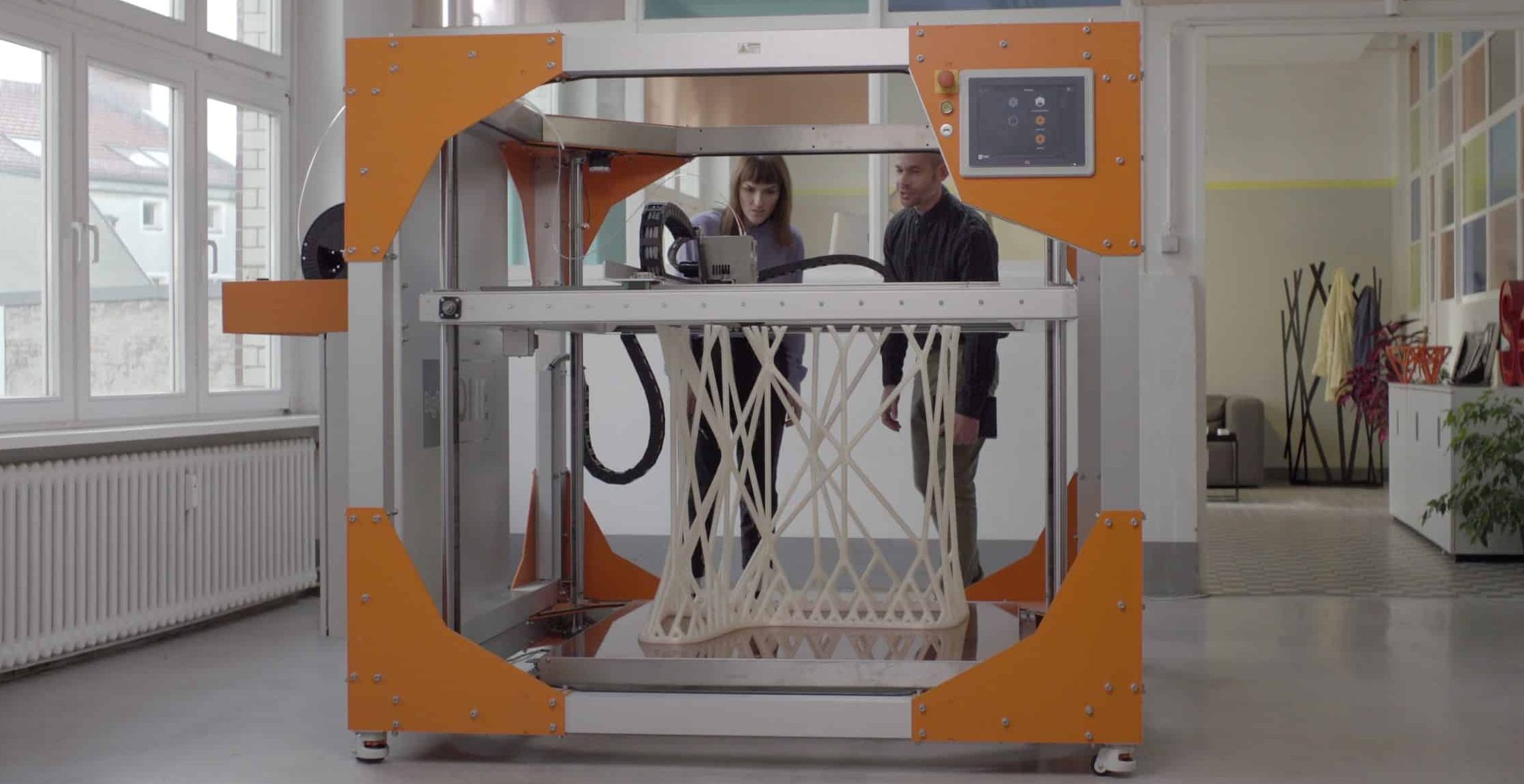

- Artistic Creations:200×200 3D printers are increasingly used for artistic purposes, allowing artists to create sculptures, models, and intricate designs. The larger build volume provides more space for complex geometries and intricate details.

- Education:200×200 3D printers are excellent tools for education, providing students with hands-on experience in design, engineering, and fabrication. The larger build volume allows for the creation of more complex and engaging projects.

- Hobbyists:These printers cater to hobbyists who enjoy creating custom items, models, and personalized projects. The larger build volume offers the flexibility to create larger and more intricate designs.

Examples of Projects Suitable for 200×200 Build Volume

Here are some examples of projects that can be successfully created using a 200×200 3D printer:

- Functional Prototypes:Imagine a prototype of a complex mechanical assembly, like a robotic arm or a gear system. A 200×200 printer allows you to create larger components that fit together realistically.

- Custom Tools:You could design and print custom tools like a specialized wrench, a jig for woodworking, or a mold for casting.

- Architectural Models:A 200×200 printer can create detailed scale models of buildings or structures, providing a tangible representation of architectural designs.

- Sculptures and Art:The larger build volume allows for the creation of intricate sculptures, busts, or even miniature scenes.

- Personalized Items:You could design and print personalized items like custom phone cases, jewelry, or decorative ornaments.

Types of 200×200 3D Printers: What Is 200×200 3d Printer

When exploring 200×200 3D printers, understanding the different technologies behind them is crucial. Each technology offers unique advantages and limitations, impacting the printing process, material compatibility, and final print quality.

Fused Deposition Modeling (FDM)

FDM is the most common 3D printing technology, known for its affordability and versatility. 200×200 FDM printers use a heated nozzle to extrude thermoplastic filament, layer by layer, building up the 3D model.The primary advantages of FDM 200×200 printers include:* Affordability:FDM printers are generally more budget-friendly compared to other technologies.

Versatility

FDM printers support a wide range of thermoplastic materials, including PLA, ABS, PETG, and Nylon.

Ease of Use

FDM printers are relatively easy to operate and maintain.However, FDM printing has limitations:* Print Resolution:FDM printers typically have lower print resolution compared to other technologies, resulting in visible layer lines.

Surface Finish

FDM prints can have a rougher surface finish compared to other technologies.

Material Limitations

FDM is primarily limited to thermoplastic materials, excluding more advanced materials like resins.Here’s a table summarizing the key specifications of FDM 200×200 printers:| Feature | Specification ||————————|————————————–|| Print Technology | Fused Deposition Modeling (FDM) || Print Volume | 200x200x200 mm || Print Resolution | 0.1-0.4 mm || Material Compatibility | Thermoplastics (PLA, ABS, PETG, etc.) || Price Range | $200-$2000 |

Stereolithography (SLA)

SLA 3D printing uses a vat of liquid photopolymer resin that is cured by a UV laser, layer by layer, to create the 3D model. This technology offers high resolution and detailed prints with smooth surface finishes.The benefits of SLA 200×200 printers include:* High Resolution:SLA printers offer significantly higher print resolution compared to FDM printers, resulting in smoother and more detailed prints.

Excellent Surface Finish

SLA prints have a very smooth surface finish, ideal for prototypes and models requiring fine details.

A 200×200 3D printer is a machine that creates three-dimensional objects layer by layer, using a process called additive manufacturing. This means the printer builds up the object from a digital model, one thin layer at a time. It’s important to remember that while a 3D printer doesn’t “collate” in the same way a regular printer does, you can think of each layer as being “collated” together to form the final object.

If you’re curious about what “collate” means in the context of a regular printer, check out this article: what does printer collate mean. So, while a 200×200 3D printer doesn’t have a collating function in the traditional sense, the process of layering is kind of like a 3D version of collating!

Material Variety

SLA printers support a wider range of photopolymer resins, including rigid, flexible, and translucent materials.However, SLA printing has some drawbacks:* Higher Cost:SLA printers are generally more expensive than FDM printers.

Post-Processing

SLA prints require post-processing, including cleaning and curing, to remove excess resin and achieve optimal strength.

Material Limitations

SLA printing is limited to photopolymer resins, which may not be suitable for all applications.Here’s a table summarizing the key specifications of SLA 200×200 printers:| Feature | Specification ||————————|————————————–|| Print Technology | Stereolithography (SLA) || Print Volume | 200x200x200 mm || Print Resolution | 0.025-0.1 mm || Material Compatibility | Photopolymer Resins || Price Range | $2000-$10,000 |

Digital Light Processing (DLP)

DLP 3D printing utilizes a projector to shine UV light onto a vat of photopolymer resin, curing specific areas to create the 3D model. This technology is known for its fast printing speeds and high resolution.The advantages of DLP 200×200 printers include:* Fast Printing Speeds:DLP printers can print much faster than SLA printers due to the simultaneous curing of entire layers.

High Resolution

DLP printers offer high print resolution, comparable to SLA printers.

Excellent Surface Finish

DLP prints have smooth surface finishes, similar to SLA prints.However, DLP printing also has its limitations:* Higher Cost:DLP printers are generally more expensive than SLA printers.

Material Limitations

DLP printing is limited to photopolymer resins, similar to SLA printing.

Post-Processing

DLP prints require post-processing, including cleaning and curing, to remove excess resin and achieve optimal strength.Here’s a table summarizing the key specifications of DLP 200×200 printers:| Feature | Specification ||————————|————————————–|| Print Technology | Digital Light Processing (DLP) || Print Volume | 200x200x200 mm || Print Resolution | 0.025-0.1 mm || Material Compatibility | Photopolymer Resins || Price Range | $3000-$15,000 |

Key Features and Considerations

Choosing the right 200×200 3D printer involves weighing several key features and considerations. These factors directly influence the printer’s capabilities, performance, and suitability for your specific needs.

Print Resolution and Layer Thickness

Print resolution and layer thickness are fundamental aspects that determine the quality and detail of your 3D prints.

- Print Resolutionrefers to the level of detail the printer can achieve, measured in microns (µm). A higher resolution (smaller micron value) results in finer details and smoother surfaces. However, higher resolution usually comes with slower printing speeds.

- Layer Thicknessis the height of each individual layer of material deposited during printing. Thinner layers produce smoother surfaces, but also increase printing time. Conversely, thicker layers are faster but can result in visible layer lines.

| Feature | Pros | Cons |

|---|---|---|

| High Print Resolution | Finer details, smoother surfaces | Slower printing speeds |

| Thin Layer Thickness | Smoother surfaces | Longer printing times |

Material Compatibility

Material compatibility determines the types of materials a 3D printer can handle.

- PLA (Polylactic Acid)is a common, readily available material known for its ease of printing and biodegradability.

- ABS (Acrylonitrile Butadiene Styrene)is a strong and durable material often used for functional parts. However, it requires a heated bed and enclosed print environment to prevent warping.

- PETG (Polyethylene Terephthalate Glycol)is a versatile material with good strength and flexibility. It’s easier to print than ABS and offers good dimensional stability.

- Nylonis a high-strength material suitable for demanding applications. It requires a heated bed and can be challenging to print.

- TPU (Thermoplastic Polyurethane)is a flexible material ideal for creating rubber-like objects. It can be challenging to print and requires a specific nozzle and print settings.

| Material | Pros | Cons |

|---|---|---|

| PLA | Easy to print, biodegradable | Lower strength, less heat resistance |

| ABS | Strong and durable | Requires heated bed and enclosed environment |

| PETG | Versatile, good strength and flexibility | Can be brittle |

| Nylon | High strength | Challenging to print, requires heated bed |

| TPU | Flexible, rubber-like properties | Challenging to print, requires specific nozzle and settings |

Printing Speed and Accuracy

Printing speed and accuracy are crucial factors that influence the efficiency and quality of your 3D prints.

- Printing Speedrefers to the rate at which the printer extrudes material. Faster speeds can save time but may compromise print quality, leading to less detailed features and rougher surfaces.

- Accuracyrefers to the printer’s ability to precisely follow the design specifications. Higher accuracy results in prints that are closer to the intended dimensions and geometry. Accuracy is influenced by factors like print resolution, layer thickness, and the printer’s mechanical precision.

| Feature | Pros | Cons |

|---|---|---|

| High Printing Speed | Faster production times | Potentially lower print quality |

| High Accuracy | Precise prints, closer to design specifications | Slower printing speeds |

Ease of Use

Ease of use is a critical factor for both beginners and experienced users.

- User-Friendly Interface: A simple and intuitive software interface makes it easier to operate the printer, load models, and adjust settings.

- Automatic Bed Leveling: This feature simplifies the process of ensuring the print bed is perfectly level, a crucial factor for consistent prints.

- Pre-Calibrated Settings: Many printers offer pre-calibrated settings for common materials, simplifying the setup and reducing the need for extensive manual adjustments.

- Good Documentation and Support: Comprehensive documentation and responsive customer support are essential for troubleshooting issues and learning how to use the printer effectively.

| Feature | Pros | Cons |

|---|---|---|

| User-Friendly Interface | Easier to operate, load models, and adjust settings | May lack advanced features |

| Automatic Bed Leveling | Simplifies bed leveling process, ensures consistent prints | Can be less precise than manual leveling |

| Pre-Calibrated Settings | Simplified setup, reduced need for manual adjustments | May not be suitable for all materials or applications |

| Good Documentation and Support | Easier to troubleshoot issues and learn how to use the printer | May not be available for all printers |

Applications and Use Cases

A 200×200 3D printer offers a generous build volume, making it suitable for a wide range of applications across various industries. This size allows for the creation of larger prototypes, functional parts, and even finished products, pushing the boundaries of what can be achieved with 3D printing.

Prototyping and Design

Prototyping is one of the most common applications for 3D printers, and a 200×200 build volume significantly expands the possibilities. This size enables the creation of larger and more complex prototypes, facilitating rapid iteration and design exploration.

- Product Design:Prototyping new products, testing designs, and exploring different functionalities. For example, a designer could create a full-scale prototype of a chair, a complex mechanical assembly, or a large-scale model of a building.

- Industrial Design:Creating prototypes of consumer products, furniture, and other objects that require a larger build volume.

- Automotive Design:Prototyping car parts, dashboards, and other components that require a larger size.

Manufacturing and Production

x200 3D printers are increasingly used in manufacturing and production for various applications. The larger build volume enables the creation of functional parts and products that are ready for use.

- Custom Parts:Producing custom parts for machinery, equipment, and tools, enabling businesses to create bespoke solutions tailored to their specific needs.

- Jigs and Fixtures:Creating jigs and fixtures for manufacturing processes, improving efficiency and accuracy.

- Production Runs:Printing small batches of finished products, allowing for quick and efficient production runs.

Art and Design, What is 200×200 3d printer

D printing has revolutionized the art and design world, and a 200×200 build volume opens up new creative possibilities.

- Sculptures and Installations:Creating large-scale sculptures, installations, and artistic pieces that require a substantial build volume.

- Custom Jewelry:Designing and printing intricate jewelry pieces, allowing for unique and personalized creations.

- Architectural Models:Creating detailed architectural models, showcasing designs and concepts in a tangible form.

Education and Research

x200 3D printers are valuable tools in education and research, facilitating hands-on learning and exploration.

- STEM Education:Introducing students to 3D printing technology, fostering creativity and problem-solving skills.

- Research and Development:Creating prototypes for research projects, testing new designs and materials, and developing innovative solutions.

- Medical Models:Printing anatomical models for medical education and research, providing realistic representations of human organs and structures.

Other Applications

Beyond these core applications, 200×200 3D printers find uses in various other industries, including:

- Aerospace:Creating parts for drones, satellites, and other aerospace applications.

- Construction:Printing concrete structures, architectural models, and custom building elements.

- Healthcare:Printing medical devices, prosthetics, and personalized implants.

- Fashion:Designing and printing custom clothing, accessories, and footwear.

Popular 200×200 3D Printer Models

The 200×200 mm build volume is a popular choice for 3D printers, offering a good balance between affordability and print size. This size is suitable for a wide range of projects, from small prototypes to larger models. Here, we’ll explore some of the most popular 200×200 3D printer models from reputable manufacturers, highlighting their key features, specifications, and pricing.

Popular 200×200 3D Printer Models

Here are some of the most popular 200×200 3D printer models available in the market:

- Creality Ender 3:A highly popular and affordable 3D printer known for its ease of use and reliability. It offers a build volume of 220x220x250 mm and features a heated bed, filament sensor, and a simple user interface. The Ender 3 is a great option for beginners and hobbyists.

Its price point is typically under $200.

- AnkerMake M5:This 3D printer boasts a 220x220x250 mm build volume, a direct drive extruder, and a heated bed. It is known for its user-friendly features, including an intuitive touchscreen interface and automatic bed leveling. The AnkerMake M5 is a good choice for users seeking a reliable and feature-rich 3D printer.

It typically costs around $500.

- Prusa i3 MK3S:The Prusa i3 MK3S is a well-regarded 3D printer known for its precision, reliability, and quality. It offers a build volume of 250x210x210 mm and features a heated bed, automatic bed leveling, and a powerful print head. The Prusa i3 MK3S is a popular choice for enthusiasts and professionals.

Its price is typically around $700.

- Ultimaker 2+:A high-end 3D printer known for its precision, reliability, and ease of use. It offers a build volume of 223x223x205 mm and features a heated bed, dual extruders, and an intuitive touchscreen interface. The Ultimaker 2+ is a good choice for professionals and users requiring high-quality prints.

Its price is typically around $2,500.

Key Features and Specifications

Here’s a table comparing the key features and specifications of the 3D printer models discussed above:

| Model | Build Volume (mm) | Technology | Extruder | Heated Bed | Price (USD) |

|---|---|---|---|---|---|

| Creality Ender 3 | 220x220x250 | Fused Deposition Modeling (FDM) | Bowden | Yes | $200 |

| AnkerMake M5 | 220x220x250 | Fused Deposition Modeling (FDM) | Direct Drive | Yes | $500 |

| Prusa i3 MK3S | 250x210x210 | Fused Deposition Modeling (FDM) | Bowden | Yes | $700 |

| Ultimaker 2+ | 223x223x205 | Fused Deposition Modeling (FDM) | Dual Bowden | Yes | $2,500 |

3D Printing Materials for 200×200 Printers

The choice of 3D printing material is crucial for achieving the desired properties and functionality of your printed object. 200×200 3D printers are versatile and support a wide range of materials, each with unique characteristics and applications. Understanding the properties, advantages, and limitations of these materials is essential for selecting the best option for your specific project.

Common 3D Printing Materials

The following table Artikels some of the most common 3D printing materials used with 200×200 printers:

| Material Type | Properties | Applications | Typical Uses |

|---|---|---|---|

| PLA (Polylactic Acid) | Biodegradable, easy to print, relatively strong, good for prototypes and functional parts. | Toys, models, household items, prototypes, functional parts. | PLA is a popular choice for beginners due to its ease of use and affordability. |

| ABS (Acrylonitrile Butadiene Styrene) | Strong, durable, impact-resistant, good for functional parts and complex designs. | Durable parts, housings, enclosures, automotive parts, prototypes. | ABS is a good choice for applications requiring high strength and impact resistance. |

| PETG (Polyethylene Terephthalate Glycol) | Strong, flexible, chemical-resistant, good for bottles, containers, and durable parts. | Food containers, bottles, packaging, prototypes, functional parts. | PETG is a good choice for applications requiring flexibility and chemical resistance. |

| TPU (Thermoplastic Polyurethane) | Flexible, elastic, durable, good for soft, flexible parts and prototypes. | Gaskets, seals, flexible parts, prototypes, footwear. | TPU is a good choice for applications requiring flexibility and durability. |

| Nylon (Polyamide) | Strong, durable, chemical-resistant, good for functional parts, prototypes, and high-performance applications. | Gears, bearings, housings, prototypes, functional parts. | Nylon is a good choice for applications requiring high strength and durability. |

| PVA (Polyvinyl Alcohol) | Water-soluble, good for support structures and temporary molds. | Support structures, temporary molds, prototypes. | PVA is often used in combination with other materials to create complex designs. |

| Carbon Fiber Reinforced PLA | Increased strength and stiffness compared to standard PLA, good for high-performance applications. | Functional parts, prototypes, automotive parts, aerospace components. | Carbon fiber reinforced PLA is a good choice for applications requiring high strength and stiffness. |

Understanding Material Properties

Each material possesses unique properties that determine its suitability for specific applications. Understanding these properties is crucial for choosing the right material for your project.

- Strength:

Strength refers to a material’s ability to withstand forces without breaking or deforming. Strong materials are suitable for applications requiring high load-bearing capacity, such as gears, housings, and structural components.

- Flexibility:

Flexibility refers to a material’s ability to bend or deform without breaking. Flexible materials are suitable for applications requiring movement or conforming to irregular shapes, such as gaskets, seals, and wearable devices.

- Durability:

Durability refers to a material’s ability to withstand wear and tear over time. Durable materials are suitable for applications requiring long-term use and resistance to harsh conditions, such as outdoor furniture, automotive parts, and industrial equipment.

- Heat Resistance:

Heat resistance refers to a material’s ability to withstand high temperatures without degrading or melting. Heat-resistant materials are suitable for applications requiring exposure to high temperatures, such as engine components, heat sinks, and food-safe containers.

- Chemical Resistance:

Chemical resistance refers to a material’s ability to withstand exposure to chemicals without degrading or reacting. Chemical-resistant materials are suitable for applications requiring contact with chemicals, such as medical devices, laboratory equipment, and industrial containers.

- Biodegradability:

Biodegradability refers to a material’s ability to decompose naturally over time. Biodegradable materials are suitable for applications where environmental impact is a concern, such as packaging, disposable products, and compostable items.

Considerations for Material Selection

When selecting a 3D printing material, several factors should be considered:

- Application:

The intended use of the printed object will dictate the required material properties. For example, a toy may require a flexible material, while a structural component may require a strong and durable material.

- Budget:

Different materials have varying costs. It’s important to consider your budget when selecting a material.

- Printer Compatibility:

Not all materials are compatible with all 3D printers. It’s essential to check the compatibility of your printer with the chosen material before purchasing.

- Print Settings:

Different materials require different print settings, such as temperature, speed, and layer height. It’s important to adjust the print settings according to the chosen material.

Choosing the Right Material for Your Project

By understanding the properties, advantages, and limitations of different 3D printing materials, you can make an informed decision about the best material for your project. Consider the intended use of the object, your budget, and the capabilities of your printer.

Setting Up and Operating a 200×200 3D Printer

Setting up and operating a 200×200 3D printer might seem daunting at first, but it’s a straightforward process with a little guidance. This section will walk you through the essential steps, from preparing your printer to printing your first 3D model.

Leveling the Print Bed

Leveling the print bed is crucial for ensuring that your prints adhere properly and achieve a smooth finish. An uneven print bed can lead to prints detaching mid-print or having uneven layers.

- Locate the leveling knobs:These are typically located on the corners of the print bed. They allow you to adjust the height of the bed relative to the print nozzle.

- Heat the print bed:Heat the print bed to the recommended temperature for the filament you are using. This will help the filament adhere better during the leveling process.

- Use a piece of paper:Place a piece of paper between the print nozzle and the print bed. The paper should slide easily but not be loose.

- Adjust the leveling knobs:Adjust the leveling knobs until the paper slides with a slight resistance in all four corners and the center of the print bed. You can use a feeler gauge for more precise measurements.

- Test print:Perform a small test print to confirm that the bed is properly leveled.

Loading Filament

Loading filament is the process of feeding the filament into the 3D printer’s extruder.

- Insert the filament:Insert the filament end into the filament guide and feed it through the extruder.

- Preheat the extruder:Preheat the extruder to the recommended temperature for your filament type.

- Start the filament feed:Use the printer’s control panel or software to start the filament feed. The extruder will push the filament through the nozzle.

- Check for filament flow:Check if the filament is flowing smoothly out of the nozzle. If it’s not, try pushing the filament manually or adjusting the extruder temperature.

- Prime the nozzle:Once the filament is flowing, prime the nozzle by extruding a small amount of filament onto the print bed. This will ensure a clean and consistent print.

Slicing Models

Slicing is the process of converting a 3D model into instructions that the 3D printer can understand.

- Choose a slicing software:There are many slicing software programs available, such as Cura, PrusaSlicer, and Simplify3D.

- Import your 3D model:Import the 3D model you want to print into the slicing software.

- Configure print settings:Adjust the print settings, such as the infill density, layer height, and printing speed. These settings will affect the quality, strength, and print time of your model.

- Select your filament type:Choose the filament type that you will be using for your print.

- Slice the model:Click the “Slice” button to convert your 3D model into G-code instructions for the 3D printer.

Initiating Prints

Once you have sliced your model and loaded the filament, you are ready to initiate the print.

- Save the G-code file:Save the generated G-code file to your computer.

- Connect the printer:Connect the 3D printer to your computer using a USB cable or wireless connection.

- Load the G-code file:Load the G-code file into the 3D printer’s control panel or software.

- Start the print:Click the “Print” button to start the printing process.

- Monitor the print:Monitor the print process to ensure that it is running smoothly. You may need to pause or cancel the print if there are any issues.

Maintenance and Troubleshooting

Keeping your 200×200 3D printer in top condition is essential for optimal performance and longevity. Routine maintenance and effective troubleshooting are key to ensuring smooth operation and high-quality prints.

Routine Maintenance

Regular maintenance is crucial for preventing problems and extending the lifespan of your 3D printer.

- Clean the print bed:After each print, gently remove any debris or leftover filament from the print bed using a scraper or a soft brush. This prevents adhesion issues and ensures a clean surface for future prints.

- Clean the nozzle:The nozzle can become clogged with filament residue, leading to poor print quality. Use a nozzle cleaning tool or a needle to remove any obstructions.

- Check and tighten screws:Over time, screws on the printer frame and hotend can loosen, affecting alignment and stability. Regularly inspect and tighten them to ensure proper operation.

- Lubricate moving parts:Bearings, sliders, and other moving parts can benefit from occasional lubrication to reduce friction and wear. Use a light oil specifically designed for 3D printers.

- Inspect the belts:Check the belts for signs of wear, cracks, or slippage. Replace them if necessary to maintain smooth and accurate movement of the print head.

- Check the wiring:Inspect the wiring for any damage, loose connections, or fraying. Ensure all connections are secure and properly insulated.

- Clean the fans:Fans play a crucial role in cooling the hotend and the electronics. Regularly clean them to prevent dust buildup and ensure proper airflow.

- Calibrate the printer:Regularly calibrate the printer to ensure accurate dimensions and consistent print quality. This involves adjusting the bed leveling, nozzle height, and other parameters.

Troubleshooting Common Issues

Encountering issues with your 3D printer is inevitable. Understanding common problems and their solutions can help you quickly resolve them.

- Nozzle clogging:A clogged nozzle can cause filament to not extrude properly, resulting in poor print quality or complete failure. This can be caused by filament residue, debris, or incorrect temperature settings.

- Print bed adhesion issues:The print may not stick to the print bed, leading to warping or detachment. This can be caused by a dirty print bed, incorrect temperature settings, or insufficient adhesion.

- Inconsistent filament extrusion:Uneven filament flow can result in uneven layers, gaps, or other print defects. This can be caused by a clogged nozzle, incorrect temperature settings, or a faulty filament feeder.

- Z-axis binding:The Z-axis is responsible for raising and lowering the print head. Binding can cause uneven layers or jerky movements. This can be caused by loose screws, worn bearings, or a clogged Z-axis rod.

- Vibrations and noise:Excessive vibrations or noise can indicate mechanical issues, such as loose screws, worn bearings, or unbalanced parts.

- Print head movement errors:Incorrect print head movement can lead to misaligned prints or skipped layers. This can be caused by loose belts, worn gears, or software glitches.

Troubleshooting Guide

| Problem | Possible Causes | Recommended Solutions |

|---|---|---|

| Nozzle Clogging | Filament residue, debris, incorrect temperature settings | Clean the nozzle with a cleaning tool or needle, adjust temperature settings, try a different filament. |

| Print Bed Adhesion Issues | Dirty print bed, incorrect temperature settings, insufficient adhesion | Clean the print bed, adjust temperature settings, use a glue stick or hairspray to improve adhesion. |

| Inconsistent Filament Extrusion | Clogged nozzle, incorrect temperature settings, faulty filament feeder | Clean the nozzle, adjust temperature settings, check the filament feeder for any obstructions. |

| Z-axis Binding | Loose screws, worn bearings, clogged Z-axis rod | Tighten screws, replace worn bearings, clean the Z-axis rod. |

| Vibrations and Noise | Loose screws, worn bearings, unbalanced parts | Tighten screws, replace worn bearings, ensure all parts are properly balanced. |

| Print Head Movement Errors | Loose belts, worn gears, software glitches | Tighten belts, replace worn gears, update firmware or troubleshoot software issues. |

Future Trends in 200×200 3D Printing

The world of 3D printing is constantly evolving, with new advancements and innovations emerging regularly. The 200×200 3D printing segment is no exception, experiencing rapid progress in areas like resolution, printing speed, and material development. This section delves into the exciting future trends shaping the landscape of 200×200 3D printing and its impact on various industries.

Improved Resolution and Detail

The quest for higher resolution in 3D printing is driven by the demand for intricate and detailed designs. 200×200 3D printers are increasingly incorporating advanced technologies to achieve finer print resolutions.

- Smaller Nozzle Sizes:Manufacturers are developing smaller nozzles, enabling the deposition of finer layers of material, leading to improved surface finish and intricate details.

- Enhanced Software Algorithms:Sophisticated software algorithms are being implemented to optimize print paths and layer adhesion, contributing to sharper edges and smoother surfaces.

- Multi-Jet Fusion Technology:This technology utilizes multiple jets to deposit and fuse powdered materials, resulting in high-resolution prints with fine details and smooth surfaces.

These advancements are opening up new possibilities for creating highly detailed prototypes, intricate jewelry, and even functional parts with complex geometries.

Faster Printing Speeds

The need for faster printing speeds is paramount in industries where time is of the essence. 200×200 3D printers are being equipped with technologies to accelerate printing processes.

- High-Speed Extrusion Systems:Improved extrusion systems with faster material flow rates enable faster deposition of material, reducing overall print times.

- Multi-Extrusion Heads:Utilizing multiple extrusion heads allows for simultaneous deposition of different materials, significantly reducing print times for complex designs.

- Parallel Processing:Advancements in software and hardware enable parallel processing, allowing for simultaneous execution of multiple tasks, resulting in faster overall printing speeds.

These innovations are empowering manufacturers to create prototypes and functional parts more efficiently, reducing lead times and accelerating product development cycles.

New Material Innovations

The development of new and advanced materials is driving innovation in 200×200 3D printing.

- Biocompatible Materials:The use of biocompatible materials is expanding the application of 3D printing in healthcare, enabling the creation of personalized implants, prosthetics, and surgical guides.

- High-Performance Polymers:The development of high-performance polymers with enhanced strength, durability, and heat resistance is opening up new possibilities for 3D printing in aerospace, automotive, and other demanding industries.

- Conductive and Magnetic Materials:The use of conductive and magnetic materials is enabling the creation of functional prototypes and parts with integrated electronics and sensors.

These material innovations are expanding the capabilities of 200×200 3D printing, enabling the creation of more sophisticated and functional products.

Future Impact on Industries

The advancements in 200×200 3D printing technology are poised to revolutionize various industries.

- Manufacturing:200×200 3D printers will play a crucial role in enabling mass customization and on-demand manufacturing, allowing companies to produce personalized products and reduce reliance on traditional manufacturing processes.

- Healthcare:3D printing is transforming healthcare by enabling the creation of personalized implants, prosthetics, and surgical tools, leading to improved patient outcomes and more effective treatments.

- Education:200×200 3D printers are becoming increasingly popular in educational institutions, providing students with hands-on learning experiences in design, engineering, and technology.

- Construction:3D printing is being explored for its potential in construction, enabling the creation of complex and customized structures with reduced waste and construction time.

The future of 200×200 3D printing is bright, with its potential to reshape industries and create new possibilities.

Detailed FAQs

What are the most popular 200×200 3D printer models?

Some popular models include the Creality Ender 3, the Anycubic i3 Mega, and the Elegoo Mars 2.

What are the different types of materials compatible with 200×200 3D printers?

Common materials include PLA, ABS, PETG, and resin.

How much does a 200×200 3D printer cost?

Prices vary depending on the features and technology used, but you can find good quality 200×200 3D printers for around $200 to $500.

What are the advantages of using a 200×200 3D printer?

Advantages include a larger build volume for creating larger objects, versatility in material compatibility, and affordability.

What are the limitations of a 200×200 3D printer?

Limitations can include print resolution, printing speed, and potential for artifacts or imperfections in prints.