What is a raft in 3D printing? It’s a thin, flat layer of material printed directly onto the print bed, acting as a stable foundation for your 3D printed object. Without a raft, your print might struggle to stick to the bed, leading to warping, curling, or even complete detachment.

Rafts are especially helpful when working with materials like ABS or PLA, which can be prone to adhesion issues, or when printing objects with large flat surfaces or intricate details.

Rafts work by providing a larger, more stable surface for the first layer of your print to adhere to. This increased surface area helps to distribute the weight of the print evenly, reducing the risk of warping or curling. The raft material is typically chosen for its strong adhesion properties, ensuring a firm bond between the raft and the print bed.

Introduction to 3D Printing Rafts

Rafts are temporary structures added to the base of a 3D printed object to improve adhesion to the print bed. They are often used in situations where the object itself has a small surface area or is prone to warping or lifting during the printing process.

Rafts act as a larger, more stable base for the object to adhere to, increasing the contact area and providing a more even distribution of heat.

Why are Rafts Needed in 3D Printing?

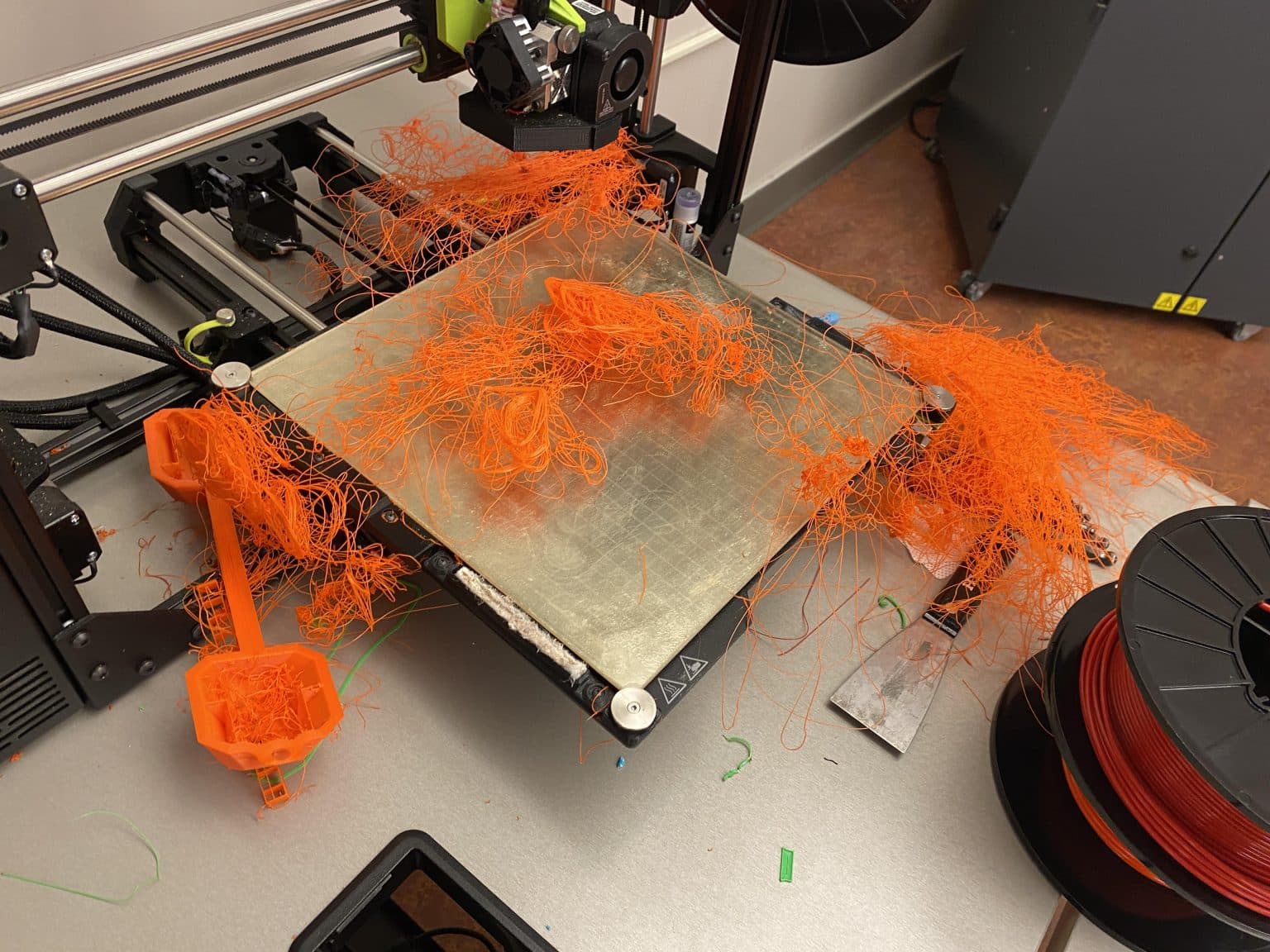

Without rafts, 3D printed objects can face various challenges, particularly in the early layers of printing. These include:

- Poor Adhesion:Objects with small surface areas or intricate designs might not have enough contact with the print bed, leading to weak adhesion and potential detachment during printing.

- Warping:As the first layers of a print cool, they can shrink and warp, especially with materials prone to warping like ABS. This can cause the object to detach from the print bed or result in an uneven surface.

- Lifting:When the first layers are not securely adhered, they can lift off the print bed during printing, leading to a failed print.

Materials and Print Settings Where Rafts are Beneficial

Rafts are particularly beneficial when printing with certain materials and settings:

- ABS:This thermoplastic is known for its tendency to warp due to its high shrinkage rate during cooling. Rafts help prevent warping and ensure a secure base for the print.

- Flexible Filaments:Flexible filaments, like TPU, often have poor adhesion to the print bed. Rafts provide a larger surface area for the first layers to adhere to, reducing the risk of lifting or detachment.

- Small Objects:Objects with small bases or intricate details can benefit from rafts, as they provide a more stable foundation for the print.

- High Print Speeds:When printing at high speeds, the rapid cooling of the first layers can lead to warping. Rafts help distribute the heat more evenly and reduce the risk of warping.

How Rafts Work in 3D Printing

Rafts are temporary support structures that are printed beneath a 3D model during the printing process. They provide a larger, flat surface for the model to adhere to, improving adhesion and preventing warping.

Raft Creation Process

The raft is created before the model itself. The 3D printer first lays down a series of layers of support material, typically in a grid pattern. This forms a flat, solid base that extends beyond the footprint of the model.

The number of layers in the raft can vary depending on the model’s size and complexity, and the printer’s settings.

Adhesion Between Raft and Print Bed

The adhesion between the raft and the print bed is crucial for successful printing. The raft material is usually chosen to have a high coefficient of friction, allowing it to grip the print bed surface firmly. This strong adhesion prevents the model from lifting or warping during the printing process.

Raft Materials

The material used for rafts is often the same as the material used for the model itself. This ensures that the raft and the model have similar properties and bond well together. Common raft materials include:

- PLA (Polylactic Acid):A biodegradable and bio-based thermoplastic, commonly used for 3D printing. It has good adhesion properties and is relatively easy to print.

- ABS (Acrylonitrile Butadiene Styrene):A strong and durable thermoplastic, often used for printing objects that require high impact resistance. ABS has excellent adhesion properties and is suitable for creating rafts.

- PETG (Polyethylene Terephthalate Glycol):A clear, strong, and durable thermoplastic with good adhesion properties. It is often used for printing objects that require a smooth finish.

- Nylon:A strong and durable thermoplastic, known for its high impact resistance and chemical resistance. Nylon is a good choice for creating rafts when printing with nylon models.

Benefits of Using Rafts in 3D Printing

Rafts are a valuable tool in 3D printing, particularly for improving adhesion and stability of prints. By providing a larger, flat surface for the first layer to adhere to, rafts help prevent warping and curling, leading to better overall print quality.

Improved Adhesion and Stability

Rafts create a more stable base for your print, ensuring that the first layer adheres firmly to the print bed. This is especially beneficial for prints with large flat areas, complex geometries, or delicate features.

- Larger Surface Area:Rafts offer a larger surface area for the first layer to bond to, minimizing the risk of detachment and improving overall print stability.

- Enhanced Bond Strength:The larger surface area of the raft increases the contact area between the print and the print bed, leading to stronger adhesion and reduced chances of warping or curling.

Prevention of Warping and Curling

Warpage and curling occur when the first layer of a print doesn’t adhere properly to the print bed, causing the print to distort or curl upwards. Rafts address this issue by:

- Uniform Heat Distribution:The raft acts as a heat sink, absorbing heat from the print and distributing it more evenly. This helps to prevent localized temperature differences that can cause warping.

- Increased Print Bed Coverage:The raft covers a larger area of the print bed, reducing the chances of uneven heating and cooling that can contribute to warping.

Impact on Print Quality and Finish

Rafts can significantly enhance the overall print quality and finish by:

- Smoother Base:Rafts provide a smooth and flat base for the print, improving the overall finish and reducing visible layer lines.

- Reduced Print Defects:The improved adhesion and stability provided by rafts minimize the occurrence of print defects such as delamination, warping, and curling, resulting in a more consistent and high-quality print.

Types of Rafts in 3D Printing

Rafts are essential in 3D printing, especially for models with large surface areas or delicate features. Different types of rafts cater to various printing needs and materials, offering distinct advantages and limitations. Understanding the types of rafts and their characteristics allows you to select the most suitable option for your 3D printing project.

Types of Rafts

The most common types of rafts used in 3D printing are:

- Solid Raft:This is the most basic type of raft, providing a solid base for the model. It is created by extruding a layer of material directly on the print bed, covering the entire build area. Solid rafts are typically used for models with large surface areas, ensuring a stable base for the print.

- Grid Raft:Unlike a solid raft, a grid raft has a pattern of holes or gaps, allowing for better adhesion and easier removal. This type of raft is ideal for models with small surface areas or intricate designs, minimizing the risk of warping and ensuring a smooth finish.

- Brim Raft:A brim raft is a thin layer of material that extends slightly beyond the model’s perimeter. It acts as a barrier, preventing the model from lifting off the print bed during printing. Brims are commonly used for models with thin walls or fragile features, providing extra support during the initial layers.

- Skirt Raft:A skirt raft is similar to a brim, but it is wider and does not directly attach to the model. It serves as a barrier and also helps to calibrate the printer’s nozzle height and ensure consistent filament flow. Skirts are particularly useful for models with complex geometries or intricate details, ensuring a clean and precise print.

- Support Raft:Support rafts are specifically designed for models with overhangs or complex geometries. They provide temporary support for the model during printing, allowing the material to solidify properly. Support rafts are typically made of a soluble material, which can be dissolved after printing, leaving a clean and finished model.

A raft in 3D printing is like a temporary base that helps your print stick to the build plate. It’s usually a thin layer of support material that gets removed after printing. It’s a bit like how you might use a piece of paper to help you write a check more neatly, but instead of paper, it’s plastic! You can learn more about printing checks on Bookkeeper here , but let’s get back to rafts.

They’re important for preventing your print from warping or detaching from the build plate, especially for complex designs with lots of overhangs.

Choosing the Appropriate Raft Type

Selecting the appropriate raft type depends on several factors, including:

- Model Size and Geometry:For large models with flat surfaces, a solid raft might be suitable. For smaller models or those with intricate details, a grid raft or a brim could be more effective.

- Material Properties:Certain materials, such as ABS or PLA, might require a specific type of raft to prevent warping or adhesion issues.

- Printing Quality and Finish:If a smooth finish is desired, a grid raft or a skirt might be preferred. For models with overhangs or complex geometries, a support raft might be necessary.

- Print Bed Adhesion:If the print bed has a tendency to release the model prematurely, a brim or a skirt could be helpful.

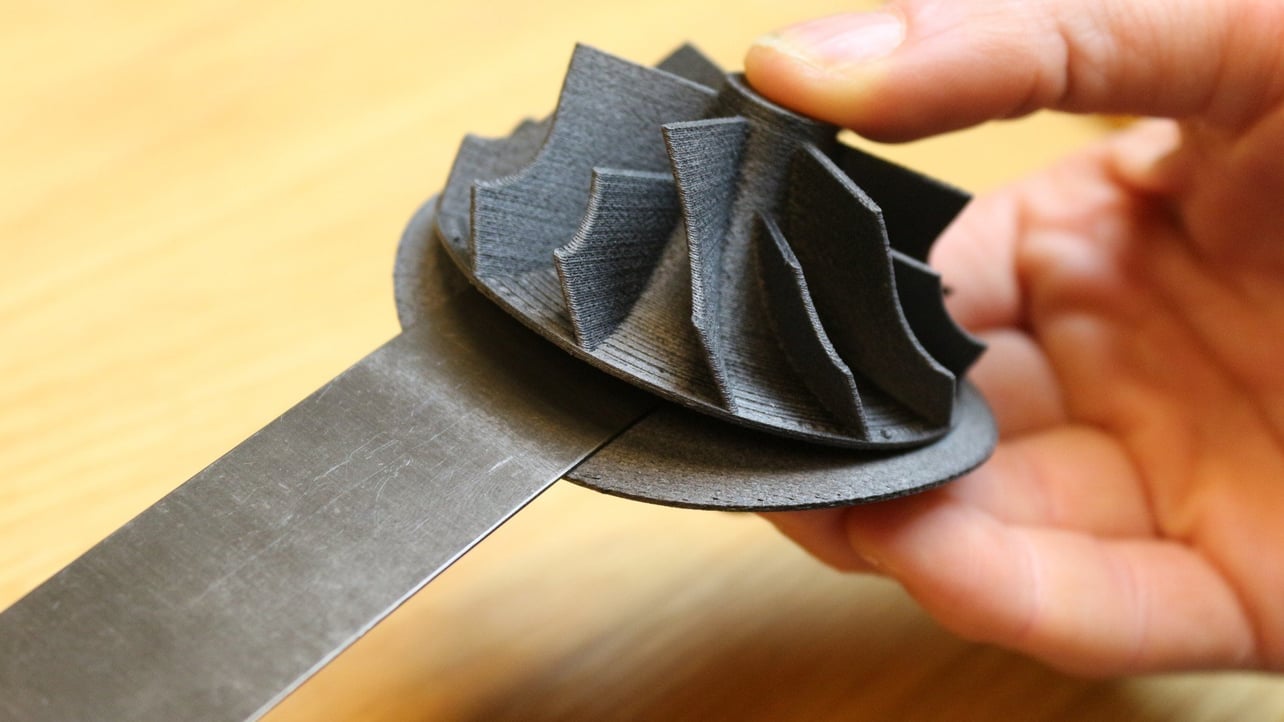

Removing Rafts from 3D Printed Objects: What Is A Raft In 3d Printing

After the printing process is complete, removing the raft is essential to reveal the final printed object. It’s a crucial step, as it can impact the overall quality and aesthetics of your print. Removing rafts properly requires care and attention to detail to avoid damaging your print.

Methods for Removing Rafts

The method you choose for removing a raft will depend on the type of raft used, the material of the print, and the complexity of the object. Here are some common methods:

- Manual Removal:This involves using a sharp tool, like a hobby knife or a scraper, to carefully pry the raft away from the print. Be cautious, as applying too much pressure can damage the object. This method works best with simple rafts and for objects with flat surfaces.

- Breaking Off:This method involves applying force to the raft, causing it to break off. This method is faster than manual removal, but it can leave behind small pieces of raft material on the print. It’s recommended for simple rafts on objects with a smooth surface.

- Soaking:This involves submerging the print in water or a solvent to soften the raft material. This makes it easier to remove, but it’s crucial to choose the right solvent for the material of the print. Be careful not to leave the print in the solvent for too long, as it could damage the object.

- Using a Heat Gun:A heat gun can be used to soften the raft material, making it easier to remove. This method is effective for most types of rafts, but it’s important to use the heat gun cautiously to avoid damaging the print.

Minimizing Damage to the Printed Object

Here are some tips for minimizing damage during raft removal:

- Use a sharp, clean tool:A dull tool can tear or scratch the print. Use a sharp blade, like a hobby knife or a scraper, for manual removal.

- Apply gentle pressure:Avoid using excessive force, as it can damage the print. Work slowly and carefully, using a scraping motion to separate the raft from the print.

- Use a lubricant:A small amount of lubricant, like WD-40, can help to loosen the raft and make it easier to remove. However, be cautious, as some lubricants can damage the print.

- Avoid bending or twisting the print:Be careful not to apply pressure to the object that could cause it to bend or twist, as this can damage the print.

- Clean the print after removal:After removing the raft, clean the print with a soft brush or a damp cloth to remove any remaining raft material.

Impact of Raft Removal on Print Finish

The method used for raft removal can impact the overall finish of the printed object. Some methods, like breaking off, can leave behind small pieces of raft material that require additional cleaning. Manual removal, while slower, can provide a cleaner finish, but it requires more care and attention to detail.

Choosing the right method for removing rafts is crucial for achieving a high-quality print finish.

When Rafts are Not Necessary

Rafts are a valuable tool in 3D printing, but they’re not always required. There are scenarios where printing without a raft can be just as successful, sometimes even preferable. Several factors determine whether a raft is necessary, and understanding these factors can help you make informed decisions about your printing process.

Factors Influencing Raft Necessity

The need for a raft is influenced by various factors, including the material used, the design of the print, and the printer’s capabilities.

- Print Material:Some materials, like ABS and PLA, are prone to warping during printing. Rafts can help prevent warping by providing a stable base for the print to adhere to. However, materials with better adhesion properties, such as PETG or Nylon, often don’t require rafts.

These materials have a stronger bond to the print bed, reducing the risk of warping.

- Print Design:Prints with large flat surfaces or thin, delicate features can benefit from rafts. Rafts provide a solid foundation that prevents these features from detaching from the print bed during printing. On the other hand, prints with a strong base and substantial geometry may not need rafts.

The print’s own structure can provide sufficient support.

- Printer Capabilities:The type of print bed and the quality of its surface can affect the need for rafts. A heated print bed can improve adhesion and reduce the need for rafts. Similarly, a print bed with a smooth, consistent surface can minimize the risk of prints detaching.

Printers with advanced features like auto-bed leveling can also improve adhesion, making rafts less necessary.

Examples of 3D Printing Applications Without Rafts

There are many 3D printing applications where rafts are typically avoided.

- Prints with Strong Bases:Objects with a wide, flat base that provides ample contact with the print bed generally don’t require rafts. For example, a model of a building with a solid foundation can be printed without a raft. The base of the print itself provides enough support.

- Prints with Support Structures:Prints that incorporate support structures, such as overhangs or complex geometries, often don’t need rafts. Support structures are designed to provide stability and prevent sagging, making a raft redundant. For instance, a model of a human figure with intricate details can be printed with support structures, eliminating the need for a raft.

- Prints with Minimal Adhesion Issues:Certain materials, like PETG or Nylon, have excellent adhesion properties and rarely require rafts. These materials adhere well to the print bed, minimizing the risk of warping or detaching. For example, a functional prototype made from PETG can be printed without a raft, as the material’s inherent adhesion provides sufficient support.

Alternative Solutions to Rafts

Rafts, while effective in promoting adhesion, are not the only solution for preventing warping and detaching in 3D printing. Various techniques can achieve similar results with their own advantages and disadvantages. Let’s explore some of these alternative methods.

Using a Build Plate Adhesion Promoter

Adhesion promoters are coatings applied to the build plate that enhance the bond between the printed object and the surface. These promoters come in various forms, including:

- Adhesive tapes: These are readily available and provide a temporary, strong adhesion. They are easily replaceable and offer a clean removal process.

- Adhesive sprays: These offer a more permanent solution compared to tapes. They are applied as a thin layer to the build plate and create a strong bond. However, they may require a cleaning process after printing.

- Build plate coatings: These are specialized coatings that permanently adhere to the build plate, providing a durable and long-lasting adhesion solution. They often require specific cleaning agents for optimal performance.

Adhesion promoters are generally easy to use and offer a cost-effective solution compared to rafts. They can be particularly beneficial for small and delicate objects, as they minimize the need for post-processing. However, the effectiveness of these promoters can vary depending on the printing material and build plate type.

Printing with a Brim

A brim is a thin, circular base layer that extends slightly beyond the perimeter of the printed object. It provides a larger contact area with the build plate, increasing adhesion and stability.

- Easy to implement: Brims are a simple feature to enable in most slicer software, making them accessible for beginners.

- Minimal post-processing: Brims are easily removed by hand after printing, requiring minimal effort compared to rafts.

- Less material consumption: Brims use less material compared to rafts, leading to a more efficient printing process.

However, brims can be less effective for complex geometries with intricate details. They may also leave a slight residue on the object’s base, which might require further cleaning.

Utilizing a Skirt

A skirt is a series of concentric circles printed around the object before the actual print begins. It serves as a “test print” to ensure proper adhesion and extrusion settings before the object itself is printed.

- Diagnostic tool: Skirts help identify potential issues with adhesion or extrusion settings before the actual print starts, allowing for adjustments to be made.

- Improved adhesion: The extruded material from the skirt can help create a more uniform and stable surface for the object to adhere to.

- Minimal material waste: Skirts are typically thin and use minimal material compared to rafts.

Skirts can be less effective for objects with intricate details, as the skirt material might interfere with the print. They also require a slight increase in printing time compared to other methods.

Employing a Support Structure, What is a raft in 3d printing

Support structures are temporary structures printed alongside the object to provide support for overhangs and intricate geometries. While primarily designed for structural support, they can also enhance adhesion by providing a larger contact area with the build plate.

- Enhanced structural support: Support structures ensure proper formation of overhangs and complex geometries, resulting in a high-quality print.

- Improved adhesion: The contact area between the support structures and the build plate can significantly enhance adhesion, especially for objects with complex shapes.

- Versatility: Support structures can be customized to suit the specific needs of the object, offering flexibility in print design.

Support structures require post-processing to remove them, which can be time-consuming and require careful handling to avoid damaging the printed object. They also add to the overall printing time and material consumption.

Optimizing Print Settings

Adjusting print settings can play a crucial role in achieving good adhesion without relying on rafts. Key parameters to consider include:

- Bed temperature: A slightly higher bed temperature can improve adhesion by softening the filament and allowing it to bond better with the build plate.

- Nozzle temperature: Optimizing the nozzle temperature for the specific filament material can ensure proper flow and adhesion.

- Print speed: A slower print speed can allow the filament to cool and solidify properly, leading to better adhesion.

- First layer height: A slightly thicker first layer can provide a stronger base for the object, improving adhesion.

- Infill density: A higher infill density can increase the object’s rigidity and reduce warping, leading to better adhesion.

While optimizing print settings can improve adhesion, it requires experimentation and understanding of the specific printer and filament material. Finding the optimal settings can be time-consuming and require multiple test prints.

FAQ

What are the different types of rafts?

There are several types of rafts, including solid rafts, grid rafts, and support rafts. Each type offers different levels of support and adhesion, so the choice depends on the specific printing needs.

How do I remove a raft from my print?

Rafts can be removed using a scraper or by gently peeling them off. It’s important to be careful not to damage the printed object during removal.

Are rafts always necessary?

No, rafts are not always necessary. For some materials and designs, good adhesion can be achieved without using a raft. Factors like the print material, bed temperature, and print design all play a role in determining whether a raft is needed.

What are some alternatives to using rafts?

Alternatives to rafts include using a brim, a skirt, or a glue stick to improve adhesion. These methods can be effective in certain situations, but they may not provide the same level of support as a raft.