What is DTF printing? It’s a revolutionary printing method that’s taking the world of apparel and textiles by storm. Unlike traditional screen printing or direct-to-garment (DTG) printing, DTF uses a unique transfer film to create vibrant, long-lasting prints on a variety of fabrics.

DTF printing starts with a digital design that’s printed onto a special film using a specialized printer. This film is then coated with a layer of powder that adheres to the ink. The powder-coated film is then transferred to the fabric using heat and pressure, creating a durable and high-quality print.

The process is surprisingly simple, yet the results are impressive.

DTF Printing

DTF printing, short for Direct-to-Film printing, is a relatively new and innovative digital printing method that offers a unique blend of versatility and high-quality results. It’s quickly gaining popularity in various industries, particularly for its ability to create vibrant and durable prints on a wide range of materials.

The Concept of DTF Printing

DTF printing is a process where a design is printed onto a special film using a digital printer. This film is then coated with a special adhesive powder, which bonds the ink to the film. Once the powder is applied, the film is heat-pressed onto the desired material, transferring the design onto the surface.

The History of DTF Printing

DTF printing emerged in the early 2010s as an alternative to traditional screen printing and heat transfer methods. It was initially developed as a way to print on fabrics with intricate designs and fine details. As technology advanced, the applications of DTF printing expanded to include a broader range of materials and uses.

The Working Principles of DTF Printing

DTF printing involves a series of steps that transform a digital design into a permanent print on a chosen material.

- Design Creation:The printing process begins with creating a digital design using a graphic design software. This design can be anything from simple text to complex artwork.

- Film Printing:The design is then printed onto a special film using a digital printer. This film is typically made of a transparent material that allows for clear and precise printing.

- Powder Application:After printing, a special adhesive powder is applied to the film. This powder bonds with the ink, creating a durable and flexible layer.

- Heat Pressing:The film with the powder is then heat-pressed onto the desired material. The heat activates the adhesive powder, transferring the design to the material.

- Cooling and Peeling:After heat pressing, the film is allowed to cool before peeling off, leaving the design permanently printed on the material.

DTF Printing Process

DTF printing, or Direct-to-Film printing, is a relatively new digital printing method that has gained popularity for its versatility and high-quality results. It involves transferring a printed design onto a film, which is then heat-pressed onto the desired substrate. This process allows for detailed designs, vibrant colors, and a smooth, durable finish.

Step-by-Step Process

The DTF printing process consists of several steps, each contributing to the final product’s quality and appearance. Here is a detailed breakdown of the process, from design to finished product:

Design Creation

The process begins with the creation of the design. The design can be created using various graphic design software, such as Adobe Illustrator or CorelDRAW. It is essential to ensure the design is high-resolution and properly formatted for printing.

Printing on Film

Once the design is finalized, it is printed onto a special DTF film using a specialized DTF printer. This printer uses a unique ink that is specifically designed for DTF printing and adheres well to the film.

Powder Application

After the design is printed onto the film, a layer of hot-melt powder is applied to the wet ink. This powder acts as an adhesive, ensuring the design transfers effectively to the substrate.

Curing the Film

The film with the powder applied is then cured in an oven. This step melts the powder, binding it to the ink and creating a durable layer.

Transferring the Design

The cured film is then placed onto the desired substrate, such as a t-shirt, tote bag, or other fabric. A heat press is used to apply heat and pressure, transferring the design from the film to the substrate.

Peeling the Film

After the heat pressing, the film is carefully peeled off, leaving the design permanently attached to the substrate.

Final Finishing

The final step involves inspecting the design and ensuring it is properly transferred. Any imperfections can be addressed at this stage.

DTF printing is a cool new method where you print directly onto a transfer film, which you then heat press onto your fabric. It’s kind of like a fancy iron-on, but with much better results. Now, if you’re wondering about the order of your pages, you might want to check out what does collate mean printer.

This lets you know how your printer arranges your pages, which can be super helpful for DTF printing projects where you need to make sure everything is in the right order for the transfer film.

Equipment and Materials

The following equipment and materials are typically used in the DTF printing process:

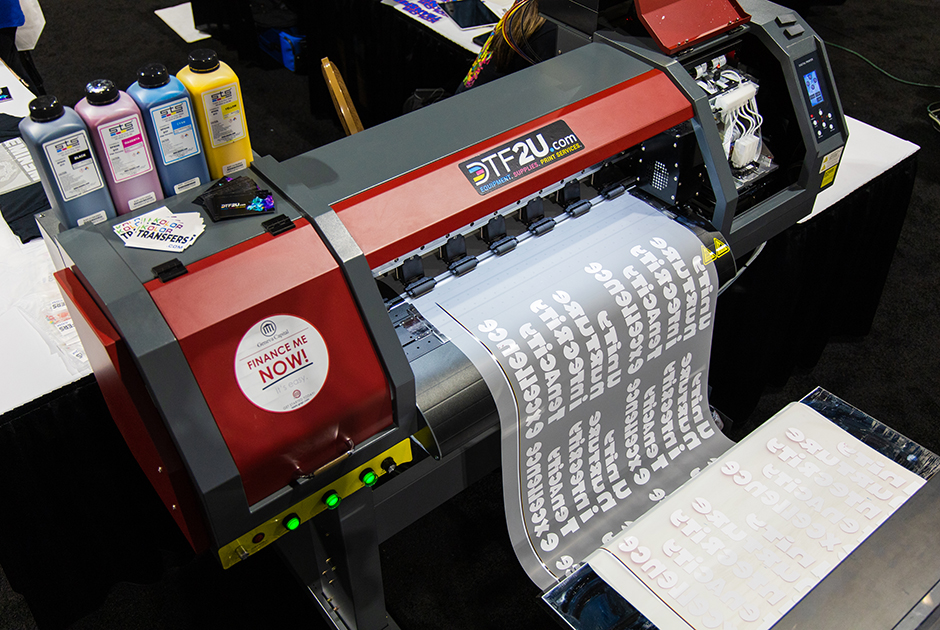

- DTF Printer: A specialized printer designed for printing onto DTF film.

- DTF Film: A special type of film that accepts the DTF ink and powder.

- DTF Ink: A unique ink specifically formulated for DTF printing.

- Hot-Melt Powder: A fine powder that acts as an adhesive, binding the ink to the film.

- Curing Oven: An oven used to melt the powder and cure the film.

- Heat Press: A machine that applies heat and pressure to transfer the design from the film to the substrate.

Advantages and Disadvantages of DTF Printing

DTF printing, or Direct-to-Film printing, has emerged as a popular and versatile printing method, offering a unique blend of benefits and drawbacks. Understanding these aspects is crucial for making informed decisions about whether DTF printing is the right choice for your specific needs.

Comparison with Other Printing Methods

DTF printing shares similarities with other printing methods, such as screen printing and direct-to-garment (DTG) printing, but also exhibits distinct differences.

- Screen printingis a traditional method that involves creating a stencil on a mesh screen and using it to transfer ink onto the fabric. This method is highly efficient for large-scale production runs, offering excellent durability and vibrant colors. However, screen printing requires a significant upfront investment in screen creation and is less suitable for intricate designs or small orders.

- DTG printinginvolves printing directly onto the fabric using specialized inkjet printers. This method offers high detail and versatility, allowing for personalized designs and small-scale orders. However, DTF printing can be more expensive for larger quantities, and the ink may not be as durable as screen printing.

- DTF printingbridges the gap between these methods, offering a balance of versatility, affordability, and durability. It allows for intricate designs and small orders, while still maintaining a high level of detail and color accuracy.

Key Advantages of DTF Printing

DTF printing offers several key advantages that make it a compelling choice for various printing applications.

- Versatility: DTF printing can be used on a wide range of fabrics, including cotton, polyester, and blends. It also allows for the creation of intricate designs with fine details, making it ideal for personalized apparel, promotional items, and even artwork.

- Durability: DTF prints are known for their durability, offering resistance to fading, cracking, and peeling. This makes DTF printing suitable for items that will be washed and worn frequently, such as t-shirts, hoodies, and bags.

- Affordability: DTF printing is generally more affordable than other methods, especially for small orders. This makes it a cost-effective option for businesses and individuals who need to print personalized items or limited-edition designs.

Potential Drawbacks of DTF Printing

While DTF printing offers numerous benefits, it also has some limitations that should be considered.

- Color Accuracy: DTF printing may not always achieve the same level of color accuracy as other methods, particularly when printing on dark fabrics. This is due to the fact that the ink is applied to a film before being transferred to the fabric, which can affect the final color appearance.

- Print Resolution: DTF printing may have a slightly lower print resolution compared to DTG printing. This means that very fine details or intricate patterns may not be as sharp or defined.

- Limited Fabric Types: While DTF printing can be used on a wide range of fabrics, it may not be suitable for all types of materials. For example, DTF printing may not be ideal for delicate fabrics or fabrics with a textured surface.

Applications of DTF Printing

DTF printing, with its versatility and high-quality output, finds applications in various industries, particularly those involving apparel, textiles, and promotional products. This printing method offers a unique blend of durability, vibrant colors, and intricate detail, making it suitable for a wide range of projects.

Apparel and Textiles

DTF printing is particularly well-suited for apparel and textile applications due to its ability to produce high-resolution, detailed designs on a variety of fabrics. It’s a popular choice for:

- T-shirts:DTF printing can be used to create custom designs on t-shirts, from simple logos to intricate artwork. The resulting prints are soft and comfortable, and they won’t crack or peel with repeated washing.

- Sportswear:The durability of DTF printing makes it ideal for sportswear, where garments are subjected to frequent washing and wear. It can be used to create team logos, player numbers, and other custom designs on jerseys, shorts, and other sportswear items.

- Fashion Apparel:DTF printing offers fashion designers the flexibility to create unique and eye-catching designs on a wide range of fabrics, from cotton to silk. The printing process allows for intricate details and gradients, enabling designers to express their creativity without limitations.

- Bags and Accessories:DTF printing can be used to create custom designs on bags, totes, backpacks, and other accessories. The prints are durable and washable, making them perfect for everyday use.

Promotional Products

DTF printing is a cost-effective and versatile option for creating personalized promotional products. It can be used to:

- Branded Merchandise:Businesses can use DTF printing to create branded merchandise such as t-shirts, hats, tote bags, and other items to promote their brand or event. The high-quality prints help create a professional and lasting impression.

- Custom Gifts:DTF printing allows for the creation of personalized gifts such as mugs, phone cases, and keychains. The ability to print intricate designs and photographs makes these gifts truly unique and memorable.

- Event Decor:DTF printing can be used to create custom banners, posters, and other decorative items for events. The vibrant colors and high-resolution prints make these items eye-catching and impactful.

Suitability for Different Materials, What is dtf printing

| Material | Suitability | Comments |

|---|---|---|

| Cotton | Excellent | DTF printing adheres well to cotton fabrics, producing vibrant and durable prints. |

| Polyester | Good | Polyester fabrics can also be printed with DTF, although pre-treatment may be required for optimal adhesion. |

| Blends | Good | DTF printing works well on fabric blends, but the specific blend may affect adhesion and print quality. |

| Leather | Limited | DTF printing is not typically recommended for leather due to the material’s texture and surface properties. |

| Plastic | Limited | DTF printing can be used on some plastics, but adhesion may vary depending on the type of plastic and its surface finish. |

Choosing the Right DTF Printer and Supplies: What Is Dtf Printing

Choosing the right DTF printer and supplies is crucial for achieving high-quality prints and maximizing your investment. Factors such as your budget, printing volume, and desired print quality will influence your decision. Let’s explore the different types of DTF printers available and the key factors to consider when selecting one.

DTF Printer Types

DTF printers can be broadly classified into two main categories: desktop printers and industrial printers. Each type has its own advantages and disadvantages, making it suitable for specific applications and production volumes.

- Desktop DTF Printers: These printers are compact and affordable, ideal for small businesses, hobbyists, or individuals starting with DTF printing. They typically use a standard A4 or A3 size printing area and offer lower print speeds compared to industrial models.

However, they are easy to set up and operate, making them a good entry point for beginners.

- Industrial DTF Printers: Industrial DTF printers are designed for high-volume production and offer larger printing areas, faster print speeds, and higher print resolutions. These printers are typically more expensive than desktop models but are essential for businesses that need to produce large quantities of prints efficiently.

Key Considerations for Choosing a DTF Printer

- Print Resolution: Higher print resolution results in sharper and more detailed prints. Desktop DTF printers typically offer resolutions ranging from 1440×1440 dpi to 2880×2880 dpi, while industrial printers can reach resolutions of 3600×3600 dpi or even higher.

- Print Speed: Print speed is an important factor to consider, especially for high-volume printing. Desktop DTF printers typically have print speeds ranging from 10 to 20 seconds per A4 page, while industrial printers can print up to 50 or even 100 pages per minute.

- Printing Area: The printing area determines the size of the designs you can print. Desktop DTF printers typically have a printing area of A4 or A3 size, while industrial printers can offer printing areas up to 60 inches wide or even larger.

- Print Quality: DTF printing offers excellent print quality, with vibrant colors and fine details. However, the quality of the print can be affected by the printer’s resolution, ink quality, and the type of film used. It’s essential to choose a printer that meets your specific quality requirements.

- Ease of Use: DTF printers can be complex to operate, especially for beginners. It’s essential to choose a printer that is easy to set up and operate and has user-friendly software.

- Price: DTF printers come in a wide range of prices, from a few hundred dollars for desktop models to tens of thousands of dollars for industrial printers. It’s important to set a budget before you start shopping for a printer and to consider the long-term cost of consumables such as ink and film.

Popular DTF Printer Models and Specifications

The following table compares the specifications and prices of some popular DTF printer models:

| Model | Type | Print Resolution | Print Speed | Printing Area | Price (USD) |

|---|---|---|---|---|---|

| [Model Name 1] | Desktop | 1440×1440 dpi | 15 seconds/A4 | A4 | $500

|

| [Model Name 2] | Desktop | 2880×2880 dpi | 10 seconds/A4 | A3 | $1000

|

| [Model Name 3] | Industrial | 3600×3600 dpi | 50 pages/minute | 60 inches | $10,000

|

| [Model Name 4] | Industrial | 3600×3600 dpi | 100 pages/minute | 100 inches | $20,000

|

Choosing the Right DTF Supplies

Choosing the right DTF supplies is just as important as selecting the right printer. The quality of the ink, film, and powder will directly impact the quality and durability of your prints.

- DTF Ink: DTF ink is specifically designed for use with DTF printers and is typically available in CMYK colors. Look for inks that are fade-resistant, water-resistant, and durable.

- DTF Film: DTF film is a special type of film that is used to transfer the printed design to the substrate. It is typically made of PET or PVC and comes in different thicknesses and finishes. Choose a film that is compatible with your printer and that meets your specific requirements for durability and adhesion.

- DTF Powder: DTF powder is used to adhere the printed design to the film. It is typically made of a blend of polymers and resins and comes in different colors and finishes. Choose a powder that is compatible with your ink and film and that provides a smooth and durable finish.

DTF Printing Techniques and Tips

DTF printing is a relatively new technology, but it has quickly become popular for its versatility and high-quality results. To achieve optimal results with DTF printing, it’s essential to understand the nuances of the process and apply some key techniques.

This section will cover essential tips and tricks to help you get the most out of your DTF printing setup.

Using High-Quality Materials and Equipment

Using high-quality materials and equipment is crucial for achieving optimal DTF printing results. The quality of your materials directly impacts the longevity, vibrancy, and overall aesthetic of your prints. Here’s a breakdown of key materials and their importance:

- DTF Film:Choose DTF film with a high-quality adhesive layer to ensure the ink adheres properly to the film and transfers effectively to the garment. A strong adhesive prevents ink from smearing or bleeding during the transfer process.

- DTF Ink:Opt for DTF inks specifically designed for DTF printing. These inks are formulated to adhere well to the film and transfer effectively to various fabrics. Consider factors like ink viscosity, color gamut, and lightfastness when selecting DTF inks.

- DTF Printer:Invest in a reliable DTF printer that can handle the demands of DTF printing. Look for a printer with a high-resolution print head, precise ink delivery, and a durable build to ensure consistent and high-quality prints.

- Hot Press:A hot press is essential for transferring the DTF film to the garment. The hot press applies heat and pressure to bond the ink to the fabric. Select a hot press with adjustable temperature and pressure settings to ensure optimal transfer results for various fabric types.

- Pre-Treatment Solution:Pre-treatment solution is crucial for preparing fabric surfaces for DTF printing. It helps the ink adhere better to the fabric, preventing it from peeling or cracking. Choose a pre-treatment solution compatible with your chosen fabric type.

Calibrating and Maintaining Your DTF Printer

Proper calibration and maintenance are essential for ensuring the longevity and optimal performance of your DTF printer. Here’s how to ensure your printer is operating at its best:

- Regular Cleaning:Clean the print head and other critical components of your DTF printer regularly to prevent ink clogs and maintain print quality. Follow the manufacturer’s instructions for cleaning procedures.

- Print Head Alignment:Ensure your print head is properly aligned to achieve accurate and sharp prints. Follow the manufacturer’s guidelines for aligning the print head. Misalignment can lead to blurry prints and uneven ink distribution.

- Color Profile Calibration:Calibrate the color profile of your DTF printer to ensure accurate color reproduction. Use a colorimeter or spectrophotometer to calibrate the printer’s color profile, achieving consistent and vibrant prints.

Future Trends in DTF Printing

DTF printing is a relatively new technology, but it has already made a significant impact on the printing industry. Its versatility, affordability, and high-quality output have made it a popular choice for businesses and individuals alike. As the technology continues to evolve, we can expect to see even more exciting developments in the years to come.

Advancements in DTF Printing Technology

The future of DTF printing is bright, with several exciting advancements on the horizon. These advancements are expected to enhance the efficiency, quality, and accessibility of DTF printing, making it even more appealing to a wider range of users.

- Improved Printheads:The development of more precise and durable printheads will lead to sharper images, smoother gradients, and finer details. This will allow for even more intricate designs and patterns to be printed with exceptional clarity.

- Enhanced Film Transfer Technology:The film transfer process is a crucial aspect of DTF printing, and advancements in this area will improve the overall quality and efficiency of the process. For instance, new film materials could offer better adhesion, quicker drying times, and greater resistance to tearing or wrinkling.

- Automated DTF Printing Systems:The integration of automation into DTF printing systems will streamline the process and reduce manual labor. Automated systems could handle tasks like film transfer, curing, and even garment preparation, increasing efficiency and reducing production time.

Growing Demand for DTF Printing

The demand for DTF printing is expected to continue growing rapidly in the coming years, driven by several factors.

- Increased Customization and Personalization:DTF printing allows for highly customized designs and personalized products, which is increasingly in demand as consumers seek unique and individualistic items. This trend is particularly evident in the fashion and apparel industry, where DTF printing is being used to create one-of-a-kind garments and accessories.

- Expansion into New Markets:DTF printing is becoming increasingly popular in various industries beyond traditional printing applications. For example, it is being used for product branding, signage, promotional materials, and even interior design. This expansion into new markets will further fuel the demand for DTF printing.

- Cost-Effectiveness and Efficiency:DTF printing offers a cost-effective solution for businesses and individuals, especially for small-scale projects and personalized orders. Its efficiency and ability to produce high-quality prints at a lower cost compared to traditional printing methods make it an attractive option for various applications.

Future Applications of DTF Printing

The versatility of DTF printing opens up a wide range of potential applications in the future.

- 3D Printing Integration:DTF printing could be integrated with 3D printing technologies to create unique and complex designs. This combination would allow for the printing of intricate patterns and textures onto 3D-printed objects, opening up new possibilities in product design and manufacturing.

- Interactive and Smart Textiles:DTF printing could be used to create interactive and smart textiles with embedded electronics and sensors. This technology could enable the development of clothing with built-in lighting, temperature control, and even communication capabilities.

- Bioprinting and Medical Applications:DTF printing could be adapted for use in bioprinting, allowing for the creation of customized medical devices, prosthetics, and even organs. The technology’s ability to print intricate designs and patterns could revolutionize the field of regenerative medicine.

Questions Often Asked

What are the main advantages of DTF printing?

DTF printing offers several advantages, including its versatility, durability, and affordability. It can be used on a wide range of fabrics, including cotton, polyester, and blends. DTF prints are also highly durable and resistant to fading and cracking. Compared to other methods like screen printing, DTF printing is often more cost-effective, especially for small runs or custom designs.

Is DTF printing suitable for all types of fabrics?

While DTF printing is highly versatile, it works best on fabrics with a smooth surface. Some fabrics, like heavily textured materials, might require pre-treatment or special techniques to achieve optimal results.

How does DTF printing compare to direct-to-garment (DTG) printing?

Both DTF and DTG printing are digital methods, but they differ in their processes and applications. DTG printing prints directly onto the fabric, while DTF uses a transfer film. DTG is generally better for intricate designs and small details, while DTF excels in producing bold, vibrant prints on a larger scale.

What are some popular DTF printer models?

The market offers various DTF printer models from different manufacturers. Some popular options include the Epson EcoTank ET-2760, the Canon PIXMA TR8620, and the Brother MFC-J995DW. These printers are known for their quality, reliability, and user-friendliness.