What is the drum in a printer? It’s the unsung hero of the printing process, a vital component that ensures crisp, clear prints. Think of it as the canvas upon which your document is painted, and the quality of the drum directly affects the final output.

From the materials used in its construction to the intricate cleaning process, the drum plays a crucial role in how your printer operates. Understanding its function and maintenance can significantly improve the lifespan of your printer and the quality of your prints.

Understanding the Drum in a Printer

The drum, often referred to as the imaging drum, is a core component in both laser and inkjet printers, playing a crucial role in the printing process. It acts as the temporary storage space for the image data before it’s transferred to the paper.

The drum in a printer is a crucial component that holds the toner and transfers it to the paper. It’s kind of like the heart of the printing process. But before you can print, you need to connect your printer to Wi-Fi, which you can learn how to do here.

Once your printer is connected, you can start printing and see how the drum works its magic!

Materials Used in Drum Construction

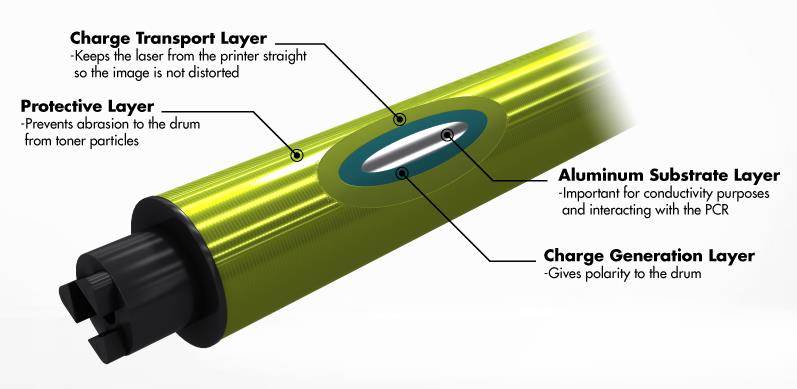

The construction of a printer drum involves a combination of materials, each contributing to its functionality and durability.

- Photoreceptor Drum:The heart of the drum, this is a light-sensitive surface coated with a photoconductive material. This material, typically selenium or organic photoconductors, possesses the unique property of changing its electrical conductivity when exposed to light. This change in conductivity is vital for the printing process.

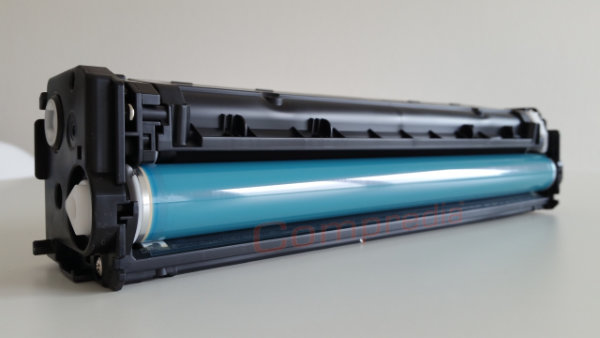

- Drum Housing:The photoreceptor drum is housed within a protective and rigid structure made of metal or plastic. This housing ensures the drum’s stability and protects it from external damage, ensuring a smooth and consistent printing experience.

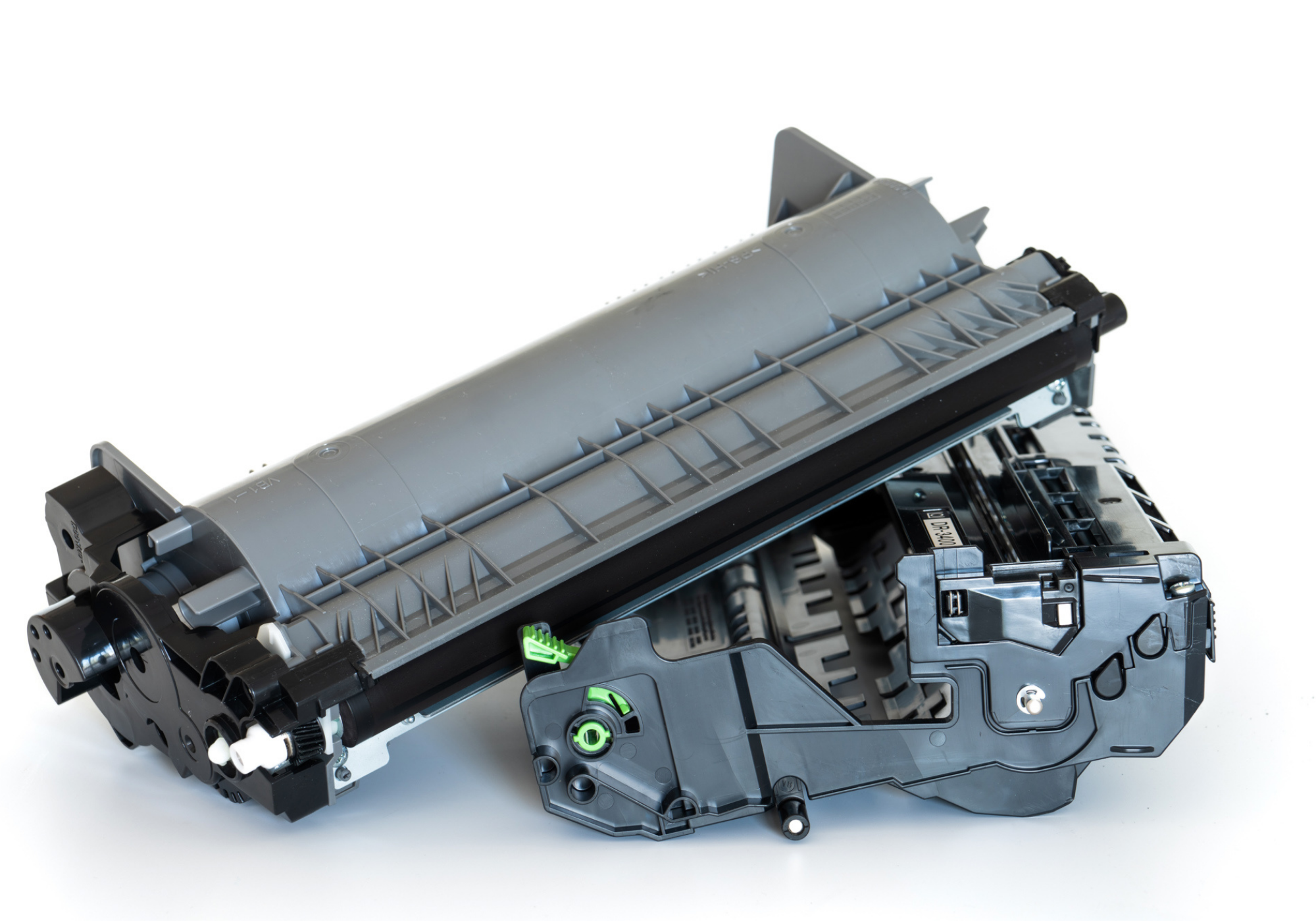

- Cleaning Blade:This blade is strategically positioned within the drum unit. It plays a crucial role in the cleaning process, removing excess toner from the drum surface after each print cycle. This ensures a clean drum for the next printing task, preventing smudging and blurry prints.

- Magnetic Roller:In laser printers, a magnetic roller is incorporated into the drum unit. This roller helps transfer the toner from the developer unit to the drum surface, adhering the toner particles to the photoreceptor drum.

Differences Between Laser and Inkjet Printer Drums

While both laser and inkjet printers utilize drums, they differ significantly in their construction and functionality due to the contrasting printing technologies they employ.

- Laser Printers:In laser printers, the drum is a cylindrical component coated with a photoconductive material. The drum’s surface is charged with static electricity, and then a laser beam scans the drum, selectively discharging areas corresponding to the image data. This creates a latent image on the drum, which attracts toner particles.

The toner is then transferred to the paper, resulting in a printed image.

- Inkjet Printers:Inkjet printers, on the other hand, employ a different approach. The drum in an inkjet printer is not directly involved in the image formation process. Instead, the drum is a rotating cylinder with a series of nozzles that spray ink onto the paper.

The drum’s primary role is to ensure accurate positioning of the paper during the printing process. It acts as a platform that moves the paper past the ink nozzles, allowing for precise ink application and sharp prints.

Cleaning Process for Printer Drums

The cleaning process for printer drums is crucial to maintaining print quality and extending the drum’s lifespan. This process involves removing excess toner and other debris from the drum’s surface.

- Automatic Cleaning:Most modern printers feature automatic drum cleaning mechanisms. These mechanisms use a cleaning blade or a combination of brushes and vacuum suction to remove toner residue from the drum’s surface after each print cycle. This automated cleaning ensures a clean drum for the next printing task, minimizing the risk of smudging or blurry prints.

- Manual Cleaning:While automatic cleaning is common, some printers may require occasional manual cleaning. This usually involves using a cleaning kit specifically designed for the printer model. The cleaning kit may include a cleaning blade, a cleaning solution, and a set of instructions.

Manual cleaning should be performed carefully, following the manufacturer’s guidelines to avoid damaging the drum.

Types of Printer Drums

Printer drums are the core components of laser and LED printers, responsible for transferring toner onto the paper. They come in various types, each with unique features and performance characteristics. Understanding the different types of printer drums is essential for choosing the right printer for your needs and ensuring optimal print quality and longevity.

Types of Printer Drums

Printer drums are categorized based on their technology, primarily revolving around the material used for the drum surface and the method of toner transfer.

- Photoreceptor Drum:The most common type of printer drum, using a photoconductive material like selenium or organic photoconductors. This material becomes electrically conductive when exposed to light, enabling the transfer of toner to the paper. Photoreceptor drums are known for their durability and reliability, offering excellent print quality and longevity.

- Organic Photoconductor Drum:These drums use organic photoconductors, which are more sensitive to light than selenium drums. This allows for faster printing speeds and lower energy consumption. However, organic photoconductor drums are typically less durable than selenium drums and may be susceptible to degradation over time.

- Liquid Toner Drum:This type of drum uses a liquid toner that is transferred to the paper using a series of rollers. Liquid toner drums offer exceptional print quality, with smoother transitions and sharper details. They are also known for their ability to produce vibrant colors.

However, liquid toner drums are more expensive than traditional toner drums and require specialized cleaning procedures.

Comparison of Drum Types

| Drum Type | Material | Toner Transfer Method | Advantages | Disadvantages |

|---|---|---|---|---|

| Photoreceptor Drum | Selenium or Organic Photoconductors | Electrostatic Transfer | Durable, Reliable, High Print Quality | May be more expensive than other drum types |

| Organic Photoconductor Drum | Organic Photoconductors | Electrostatic Transfer | Faster Printing Speeds, Lower Energy Consumption | Less Durable than Selenium Drums, May Degrade over Time |

| Liquid Toner Drum | Liquid Toner | Roller Transfer | Exceptional Print Quality, Vibrant Colors | More Expensive, Requires Specialized Cleaning Procedures |

Drum Maintenance and Replacement

Just like any other printer component, the drum needs regular maintenance and eventual replacement. Understanding the signs that indicate a drum is nearing the end of its lifespan is crucial for ensuring optimal print quality and preventing costly repairs. This section will guide you through recognizing these signs, replacing the drum effectively, and extending its lifespan.

Identifying Signs of a Worn-out Drum

Recognizing the signs of a worn-out drum is essential to avoid printing issues and ensure optimal print quality. Several factors can indicate that your drum needs replacement.

- Uneven or Faded Prints:If you notice uneven or faded prints, it could be a sign of a worn-out drum. The drum’s surface may have scratches or wear, causing the toner to distribute unevenly.

- Vertical Lines or Streaks:Vertical lines or streaks on your printed documents are another indication of a worn-out drum. These lines are often caused by scratches or debris on the drum’s surface.

- Ghosting:Ghosting, or the appearance of faint images from previous prints on new documents, is a common sign of a worn-out drum. This happens when toner particles remain on the drum’s surface after printing.

- Drum Error Messages:Modern printers often display error messages when they detect issues with the drum. If you see a message related to the drum, it’s a clear sign that it needs replacement.

Replacing a Printer Drum

Replacing a printer drum is a relatively straightforward process. Follow these steps to ensure a smooth replacement:

- Turn off the printer and unplug it.This is essential for safety and prevents any electrical shocks.

- Open the printer cover and locate the drum.The drum is typically located near the toner cartridge, often in a separate compartment.

- Release the drum latch or lever.This will allow you to remove the drum from the printer.

- Carefully remove the old drum.Handle the drum with care to avoid damaging the sensitive surface.

- Insert the new drum.Align the drum correctly and ensure it’s securely in place.

- Close the printer cover and plug it back in.

- Turn on the printer and wait for it to initialize.

Importance of Using Compatible and Genuine Drum Cartridges, What is the drum in a printer

Using compatible and genuine drum cartridges is crucial for maintaining optimal print quality and avoiding potential damage to your printer.

- Genuine Drum Cartridges:Genuine drum cartridges are manufactured by the printer manufacturer and are designed specifically for your printer model. They offer the best performance and compatibility, ensuring optimal print quality and longevity.

- Compatible Drum Cartridges:Compatible drum cartridges are manufactured by third-party companies and are designed to work with specific printer models. While they may be cheaper than genuine cartridges, they might not offer the same level of performance and quality.

Extending the Lifespan of a Printer Drum

While printer drums have a limited lifespan, you can take steps to extend their longevity and maximize their performance.

- Regular Cleaning:Regularly cleaning the drum’s surface can remove dust and debris that can accumulate and affect print quality. Use a soft, lint-free cloth to gently wipe the drum surface.

- Avoid Exposing the Drum to Direct Sunlight:Direct sunlight can damage the drum’s surface and reduce its lifespan. Store the drum in a cool, dry place when not in use.

- Use High-Quality Toner:Using high-quality toner can help extend the lifespan of the drum. Avoid using generic or cheap toner cartridges, as they may contain impurities that can damage the drum.

- Proper Handling:Handle the drum with care to avoid scratching or damaging the sensitive surface. Avoid dropping or mishandling the drum.

Drum and Print Quality: What Is The Drum In A Printer

The drum plays a crucial role in determining the quality of your printed documents. A healthy drum ensures sharp, clear prints, while a damaged or worn-out drum can lead to various print quality issues. Understanding the connection between drum condition and print quality is essential for maintaining optimal printing performance.

The drum’s primary function is to transfer toner onto the paper. It’s coated with a photosensitive material that responds to light, creating a latent image that attracts toner particles. If the drum is damaged or worn, it can affect the transfer process, leading to problems like uneven toner distribution, faded prints, or streaks.

Drum Defects and Their Effects on Printing

Various factors can contribute to drum defects, each impacting print quality in unique ways.

- Scratches or Abrasions:These can occur from improper handling, foreign objects entering the printer, or wear and tear. Scratches on the drum surface can lead to white streaks or lines on printed documents.

- Static Discharge:Excessive static electricity can attract dust and debris to the drum, causing black specks or blotches on prints.

- Toner Adhesion Issues:A worn-out drum can lose its ability to hold toner properly, resulting in faded or patchy prints.

- Drum Wear:Over time, the drum surface can wear down, leading to uneven toner distribution and blurry prints.

- Drum Cleaning Issues:If the drum isn’t cleaned regularly, accumulated toner particles can create streaks or smudges on prints.

Troubleshooting Printing Issues Related to the Drum

Several symptoms can indicate a drum-related issue.

- Streaks or Lines:These often point to scratches or abrasions on the drum surface.

- Faded or Patchy Prints:A worn-out drum or toner adhesion issues can cause faded or patchy prints.

- Black Specks or Blotches:Static discharge can attract dust and debris to the drum, leading to black specks or blotches on prints.

- Uneven Toner Distribution:Drum wear or cleaning issues can cause uneven toner distribution, resulting in light or dark areas on prints.

Examples of Common Print Defects and Their Corresponding Drum Issues

Here are some common print defects and their likely causes related to the drum:

| Print Defect | Possible Drum Issue |

|---|---|

| White streaks or lines | Scratches or abrasions on the drum surface |

| Black specks or blotches | Static discharge attracting dust and debris to the drum |

| Faded or patchy prints | Worn-out drum or toner adhesion issues |

| Uneven toner distribution | Drum wear or cleaning issues |

Query Resolution

What is the lifespan of a printer drum?

The lifespan of a printer drum varies depending on usage and the type of printer. On average, a drum can last anywhere from 10,000 to 50,000 pages.

How do I know if my printer drum needs replacing?

Common signs include faded or streaky prints, horizontal lines, or blank pages. You can also check the drum’s condition by looking for scratches or damage.

Can I use a generic printer drum in my printer?

While generic drums may be cheaper, they can sometimes cause compatibility issues and may not deliver the same print quality as genuine cartridges.