What is UV printing? It’s a revolutionary printing process that utilizes ultraviolet (UV) light to cure inks, instantly solidifying them for a durable, high-quality finish. This technology has evolved from its humble beginnings in the 1970s, becoming a cornerstone in various industries, from signage and packaging to textiles and electronics.

UV printing stands out due to its exceptional print quality, vibrant colors, and remarkable durability. It’s a versatile technique that can be applied to a wide range of substrates, including plastics, metals, glass, and even wood. Let’s delve deeper into the intricacies of this cutting-edge printing method.

What is UV Printing?

UV printing is a specialized printing method that utilizes ultraviolet (UV) light to instantly cure inks, making them dry and resistant to smudging or scratching. It’s a versatile technique used for a wide range of applications, from high-quality graphics and packaging to industrial and even medical purposes.

History of UV Printing

UV printing technology has evolved over several decades, with significant advancements in ink formulations, curing lamps, and printing equipment. Early forms of UV printing emerged in the 1970s, primarily for specialized applications like screen printing. The development of digital UV printing in the late 1990s revolutionized the industry, offering greater flexibility and speed.

Comparison with Other Printing Methods

UV printing offers distinct advantages compared to traditional printing methods like offset and digital printing.

Offset Printing

Offset printing, a widely used technique, involves transferring ink from a plate to a rubber blanket and then to the printing surface. This process is cost-effective for large print runs but requires a longer setup time and can be less flexible for intricate designs.

Digital Printing

Digital printing, on the other hand, utilizes digital files to create prints directly onto the substrate. It’s known for its speed and customization options but often lacks the durability and vibrancy of UV printing.

UV printing offers a unique combination of high quality, durability, and speed, making it a popular choice for various applications.

How UV Printing Works

UV printing is a specialized printing method that utilizes ultraviolet (UV) light to cure inks instantly, making it a versatile and efficient process for a wide range of applications. This process differs significantly from traditional printing methods that rely on drying inks through evaporation.

UV printing is a popular choice for printing on a wide range of materials, but it’s not the only game in town. If you’re looking for a different approach, you might want to check out a DTF printer, which stands for Direct to Film.

What is a DTF printer ? In short, it’s a digital printing method that uses a special film to transfer designs onto fabrics. While UV printing excels at creating durable prints on hard surfaces, DTF printing is ideal for soft materials like t-shirts and hoodies.

Let’s explore the step-by-step process of UV printing and delve into the unique advantages it offers.

UV Printing Process

UV printing involves a series of steps, each contributing to the final print output. Here’s a breakdown of the process:

- Image Preparation:The printing process begins with the creation of a digital image file, which is then processed and prepared for printing. This step involves ensuring the image is of high resolution and optimized for the specific printing process.

- Image Transfer:The prepared image is then transferred to the printing device, typically a large-format printer. This transfer process involves converting the digital image into a format that the printer can understand and reproduce.

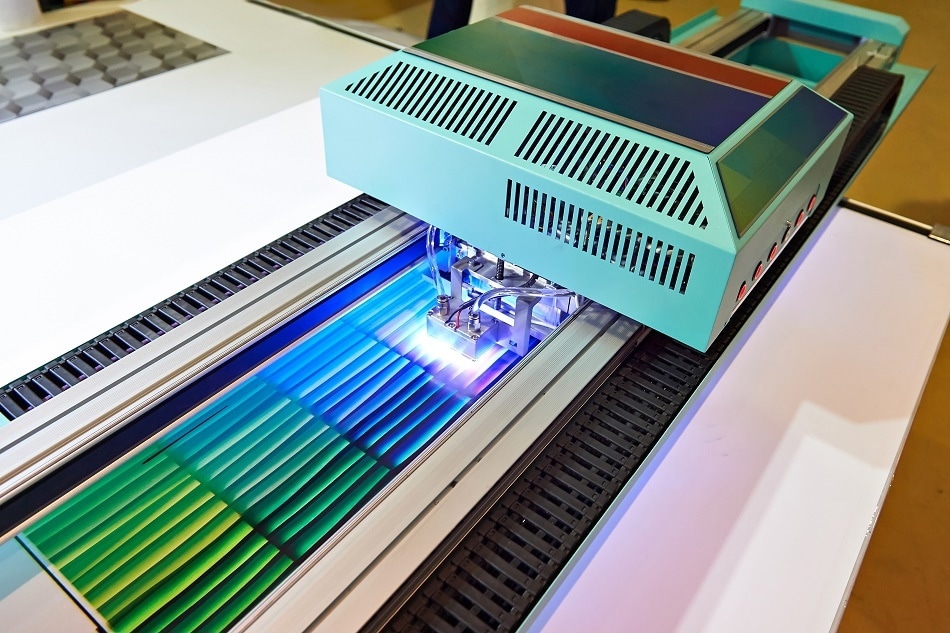

- Ink Application:The printing device applies UV inks onto the substrate, which can be a variety of materials such as paper, canvas, metal, or plastic. The inks are dispensed precisely onto the substrate, following the digital image data.

- UV Curing:The crucial step in UV printing is the curing process. Here, UV lamps emit ultraviolet light onto the wet ink, triggering a chemical reaction that instantly solidifies the ink. This process is known as photopolymerization.

- Post-Processing:Once the ink is cured, the print may undergo post-processing steps, depending on the application. These steps can include lamination, coating, or cutting, further enhancing the print’s durability, finish, or functionality.

UV Ink Curing

UV ink curing is a unique process that distinguishes UV printing from traditional methods. The inks used in UV printing contain photoinitiators, which are light-sensitive chemicals that initiate a polymerization reaction when exposed to UV light. This reaction causes the liquid ink to solidify rapidly, forming a durable and scratch-resistant coating.

Advantages of UV Curing

- Instant Curing:UV curing offers the significant advantage of instant drying, eliminating the need for lengthy drying times associated with traditional inks. This allows for immediate handling of the printed material and faster production turnaround times.

- High Durability:UV-cured inks form a tough, scratch-resistant surface, making them suitable for applications where durability is essential, such as signage, floor graphics, and product packaging.

- Vibrant Colors:UV inks offer a wide color gamut and high color saturation, producing vibrant and eye-catching prints. The inks’ ability to adhere to various substrates without fading ensures long-lasting color vibrancy.

- Eco-Friendly:UV curing processes often use less energy than traditional drying methods, making them a more environmentally friendly option. Furthermore, UV inks typically contain fewer volatile organic compounds (VOCs), reducing harmful emissions.

UV Printing Equipment

UV printing utilizes specialized equipment designed to handle the unique aspects of this process. The primary components of a UV printing system include:

- UV Printer:The core component of the system, the UV printer, is responsible for applying UV inks onto the substrate and exposing the inks to UV light for curing. UV printers come in various sizes and configurations, catering to different applications and production volumes.

- UV Lamps:UV lamps are essential for curing the inks. They emit high-intensity UV light, triggering the polymerization reaction in the ink. The type and intensity of the UV lamps used depend on the specific application and ink formulation.

- UV Inks:UV inks are specially formulated to cure rapidly when exposed to UV light. They are available in a wide range of colors and finishes, catering to various printing needs.

- Substrate Handling System:UV printing often involves handling large and rigid substrates, requiring specialized systems for feeding and transporting the material through the printer.

Applications of UV Printing

UV printing’s versatility and unique advantages have made it a popular choice for a wide range of applications, including:

- Signage and Display Graphics:UV printing is widely used for creating durable and vibrant signage, displays, and promotional materials. The high-resolution prints and long-lasting colors make them ideal for outdoor and indoor applications.

- Product Packaging:UV printing offers a high level of detail and vibrant colors, making it an excellent choice for packaging labels, boxes, and other printed materials. The durable inks ensure the packaging remains attractive and intact throughout its lifespan.

- Industrial Applications:UV printing is used in various industrial settings for printing on materials like metal, plastic, and glass. The process’s ability to cure inks quickly and adhere to different surfaces makes it ideal for industrial applications, such as product branding, component marking, and circuit board printing.

- Fine Art and Photography:UV printing offers exceptional color accuracy and detail, making it a popular choice for reproducing fine art prints, photographs, and other high-quality images. The durable prints can be displayed for extended periods without fading or deterioration.

Advantages of UV Printing

UV printing offers several advantages over traditional printing methods, making it a popular choice for various applications. These advantages stem from the unique properties of UV inks and the printing process itself.

Print Quality

UV printing excels in delivering high-resolution, vibrant, and detailed prints. The inks cure instantly upon exposure to UV light, resulting in crisp lines, sharp images, and rich colors. This precision is particularly valuable for applications requiring intricate designs or photographic quality.

Durability

UV inks are known for their exceptional durability. The instant curing process creates a hard, scratch-resistant surface that can withstand harsh conditions, including exposure to sunlight, moisture, and abrasion. This makes UV printing ideal for applications requiring long-lasting prints, such as outdoor signage, promotional materials, and industrial labeling.

Versatility

UV printing can be applied to a wide range of substrates, including plastics, glass, metal, wood, and even textiles. This versatility allows for creative applications across industries, from packaging and signage to personalized products and industrial components.

Applications Across Industries

The advantages of UV printing have made it a valuable tool in various industries. For example:

- Packaging:UV printing produces high-quality packaging with vibrant colors and intricate designs, enhancing brand appeal and product presentation.

- Signage:The durability and weather resistance of UV prints make them ideal for outdoor signage, ensuring long-lasting visibility and brand messaging.

- Promotional Materials:UV printing allows for the creation of high-impact promotional materials, such as brochures, flyers, and posters, with sharp details and vivid colors.

- Industrial Labeling:UV printing provides durable and weather-resistant labels for industrial applications, ensuring product identification and traceability.

Comparison with Other Printing Methods

| Feature | UV Printing | Offset Printing | Digital Printing |

|---|---|---|---|

| Print Quality | High-resolution, vibrant colors, sharp details | High-quality, consistent color reproduction | Variable quality, depending on printer and ink |

| Durability | Highly durable, scratch-resistant, weather-resistant | Moderate durability, susceptible to fading and scratching | Variable durability, depending on ink and substrate |

| Versatility | Wide range of substrates, including plastics, glass, metal, wood | Limited to paper and cardstock | Variable substrate compatibility, depending on printer |

| Speed | Moderate speed, suitable for medium to high-volume printing | High speed, ideal for large-scale printing | High speed, suitable for short-run and personalized printing |

| Cost | Moderate cost, suitable for medium to high-volume printing | Low cost per unit, ideal for large-scale printing | Variable cost, depending on printer and ink |

Applications of UV Printing

UV printing is a versatile technology with a wide range of applications across various industries. It’s known for its high-quality, durable prints and ability to work on a diverse range of materials.UV printing is used in numerous applications, from producing personalized products to creating large-scale signage.

It’s a popular choice for businesses looking to create high-impact visuals that are both aesthetically pleasing and long-lasting.

Printing on Different Materials

UV printing excels at adhering to various surfaces, making it a preferred choice for a wide range of applications.

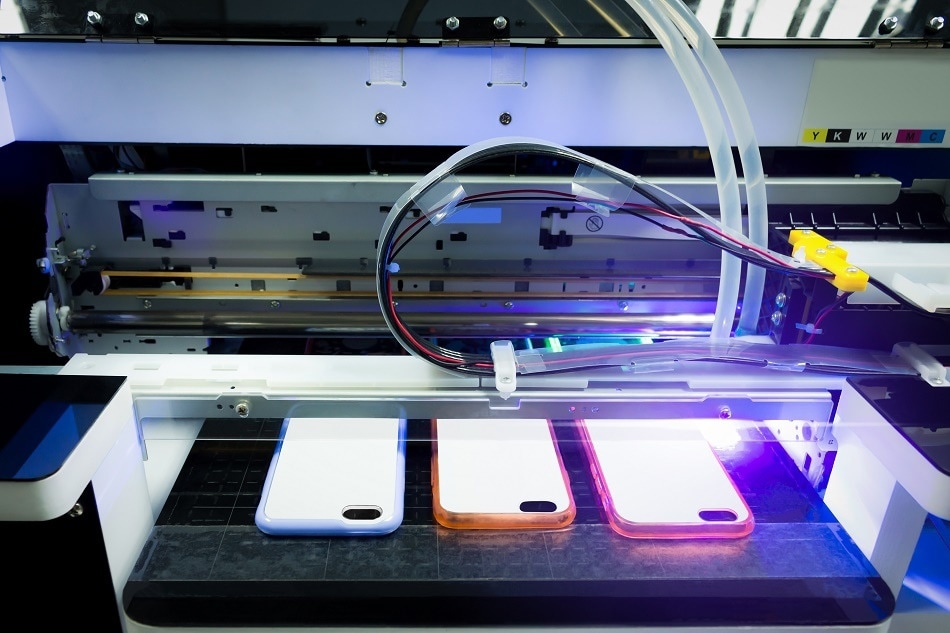

- Plastic:UV printing is ideal for printing on plastic products like phone cases, promotional items, and packaging. It creates vibrant, durable prints that resist scratches and fading.

- Metal:UV printing is used for printing on metal surfaces, such as signage, automotive parts, and industrial equipment. It provides a high-quality, durable finish that can withstand harsh environments.

- Wood:UV printing is used for printing on wooden surfaces, such as furniture, signage, and decorative items. It allows for intricate designs and vibrant colors to be applied to wood, enhancing its aesthetic appeal.

- Glass:UV printing is used for printing on glass surfaces, such as windows, mirrors, and decorative items. It creates high-resolution prints that are scratch-resistant and fade-proof, enhancing the look of glass products.

- Textile:UV printing is used for printing on fabrics, such as t-shirts, banners, and flags. It produces high-quality prints with vibrant colors that are durable and washable.

Examples of UV Printing Applications

Here are some examples of how UV printing is used in different industries:

- Promotional Products:UV printing is used to create personalized promotional products like pens, mugs, keychains, and phone cases. These items are often used for branding, advertising, and customer engagement.

- Signage and Displays:UV printing is widely used for creating high-quality signage, displays, and posters. Its ability to print on various materials like acrylic, PVC, and metal makes it suitable for both indoor and outdoor applications.

- Packaging:UV printing is used for printing on packaging materials like cartons, boxes, and labels. It provides vibrant colors and detailed graphics, enhancing the aesthetics and brand appeal of products.

- Industrial Applications:UV printing is used for printing on industrial parts, components, and equipment. It allows for the creation of durable, high-resolution prints that can withstand harsh environments and industrial processes.

- Fine Art and Photography:UV printing is used to create high-quality prints of fine art and photography. It allows for the reproduction of intricate details and vibrant colors, making it suitable for museum-quality prints.

Emerging Trends and Future Applications

UV printing technology is constantly evolving, leading to new and innovative applications. Here are some emerging trends and future applications:

- 3D Printing:UV printing is being integrated into 3D printing processes to create high-resolution, multi-colored 3D objects. This allows for the creation of intricate designs and complex structures.

- Sustainable Printing:UV printing is becoming increasingly popular in sustainable printing applications due to its ability to print on recycled materials and reduce waste.

- Personalized Products:UV printing is being used to create highly personalized products, such as custom-designed shoes, clothing, and accessories. This allows for greater individual expression and customization.

- Interactive Printing:UV printing is being used to create interactive prints that respond to touch or light. This opens up new possibilities for marketing, education, and entertainment.

Considerations for UV Printing

UV printing, while offering numerous advantages, also presents certain considerations that should be factored into your decision-making process. Understanding these limitations and cost implications can help you determine if UV printing is the right choice for your specific needs.

Cost of UV Printing, What is uv printing

The cost of UV printing can vary depending on factors such as the size and complexity of the print job, the type of materials used, and the volume of prints required. However, in general, UV printing is considered a more expensive printing method than traditional offset printing.

This is due to the specialized equipment and inks used in UV printing, as well as the higher energy consumption required for curing the inks. Here’s a comparison of UV printing costs with other printing methods:

| Printing Method | Cost (Approximate) | Advantages | Disadvantages |

|---|---|---|---|

| UV Printing | Higher | High quality, durability, versatility | Higher initial investment, higher running costs |

| Offset Printing | Lower | Large print runs, cost-effective for high volumes | Less versatile, limited substrate options |

| Digital Printing | Moderate | On-demand printing, short turnaround times | Lower quality than UV printing, limited substrate options |

For small print runs or projects requiring high-quality, durable prints, UV printing can be a cost-effective option despite its higher initial investment. However, for large-volume print jobs, offset printing may be a more economical choice.

Limitations of UV Printing

While UV printing offers many benefits, it also has certain limitations that you should be aware of:

- Limited Substrate Compatibility:UV inks are designed to cure on specific materials, such as rigid substrates like glass, metal, and plastic. They may not be suitable for all types of materials, such as textiles or porous surfaces.

- Higher Energy Consumption:UV curing requires high-intensity UV lamps, which consume significant energy. This can be a concern for businesses seeking environmentally friendly printing solutions.

- Potential for Color Shift:The UV curing process can sometimes cause slight color shifts, particularly with certain inks and substrates. It’s important to conduct color matching tests before starting large print runs.

- Limited Print Area:The size of the print area is limited by the size of the UV printing machine. If you need to print large-format designs, you may need to consider alternative printing methods.

Choosing the Right UV Printing Solution

The best UV printing solution for your needs will depend on several factors, including:

- Print Volume:If you need to print large volumes of materials, offset printing may be a more cost-effective option. However, for smaller print runs or projects requiring high-quality prints, UV printing can be a suitable choice.

- Substrate Type:UV printing is best suited for rigid substrates like glass, metal, and plastic. If you need to print on textiles or other porous surfaces, you may need to consider alternative printing methods.

- Budget:UV printing can be more expensive than other printing methods. It’s important to consider your budget and the overall cost of the project before making a decision.

- Quality Requirements:UV printing offers high-quality, durable prints. If you need high-resolution prints with excellent color accuracy and durability, UV printing can be a good choice.

Expert Answers

What are the benefits of UV printing over traditional printing methods?

UV printing offers several advantages, including faster drying times, superior color vibrancy, and greater durability compared to traditional methods. It also allows for printing on a wider range of substrates.

Is UV printing environmentally friendly?

UV printing is considered more environmentally friendly than some traditional printing methods because it uses less energy and produces less waste. The inks used in UV printing are also generally solvent-free and non-toxic.

What types of applications are UV printing best suited for?

UV printing is well-suited for a wide range of applications, including signage, packaging, promotional materials, textiles, and even personalized products.

Is UV printing expensive?

The cost of UV printing can vary depending on factors like the size and complexity of the project, the substrate used, and the volume of printing. However, the long-lasting quality and durability of UV prints often make it a cost-effective choice in the long run.